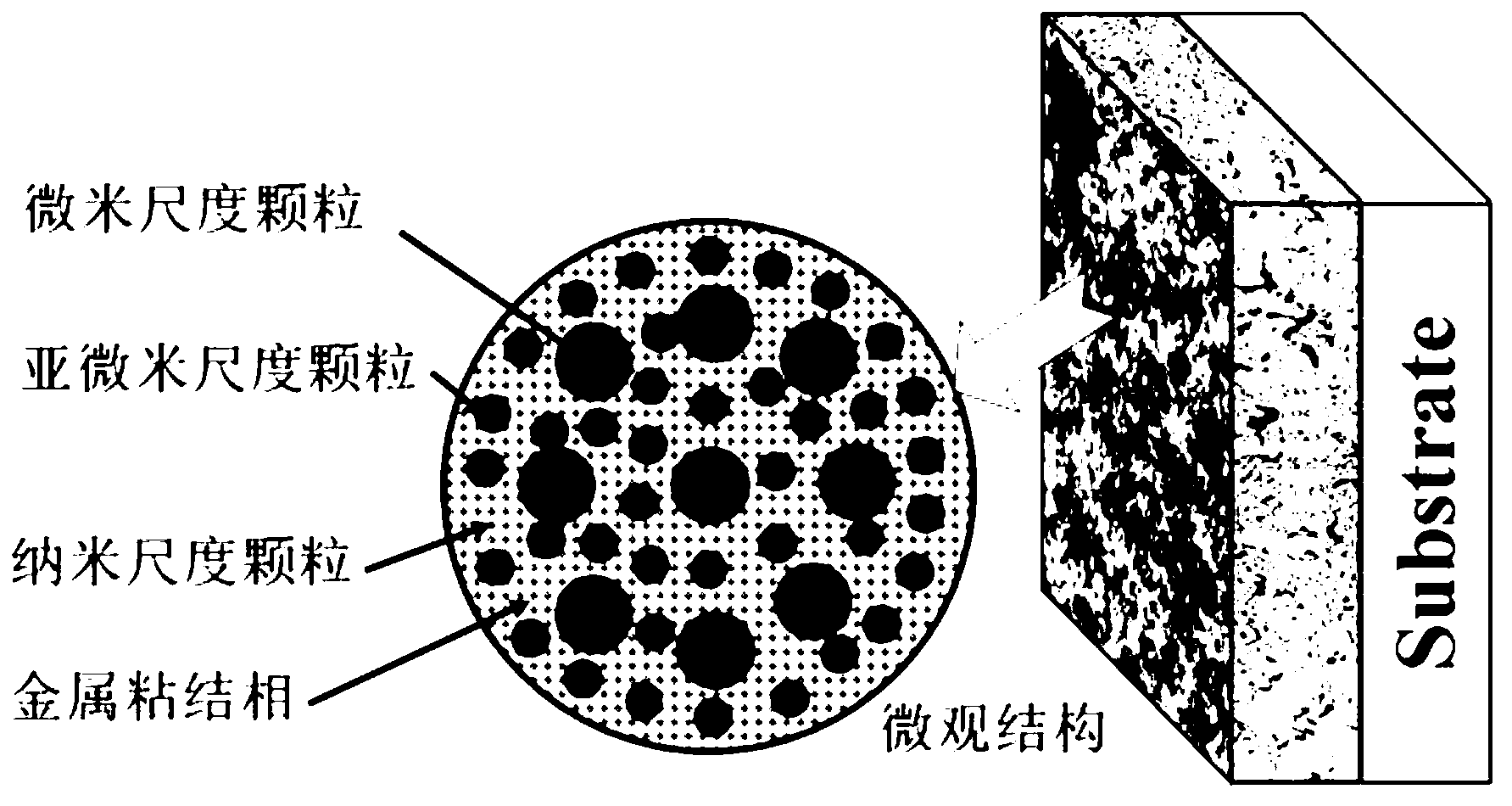

Metal ceramic coating provided with multi-scale WC (wolfram carbide) crystal grains and preparation method

A cermet coating, multi-scale technology, applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of toughness decline, unable to meet the technical requirements of engineering machine parts remanufacturing, and achieve the goal of improving toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

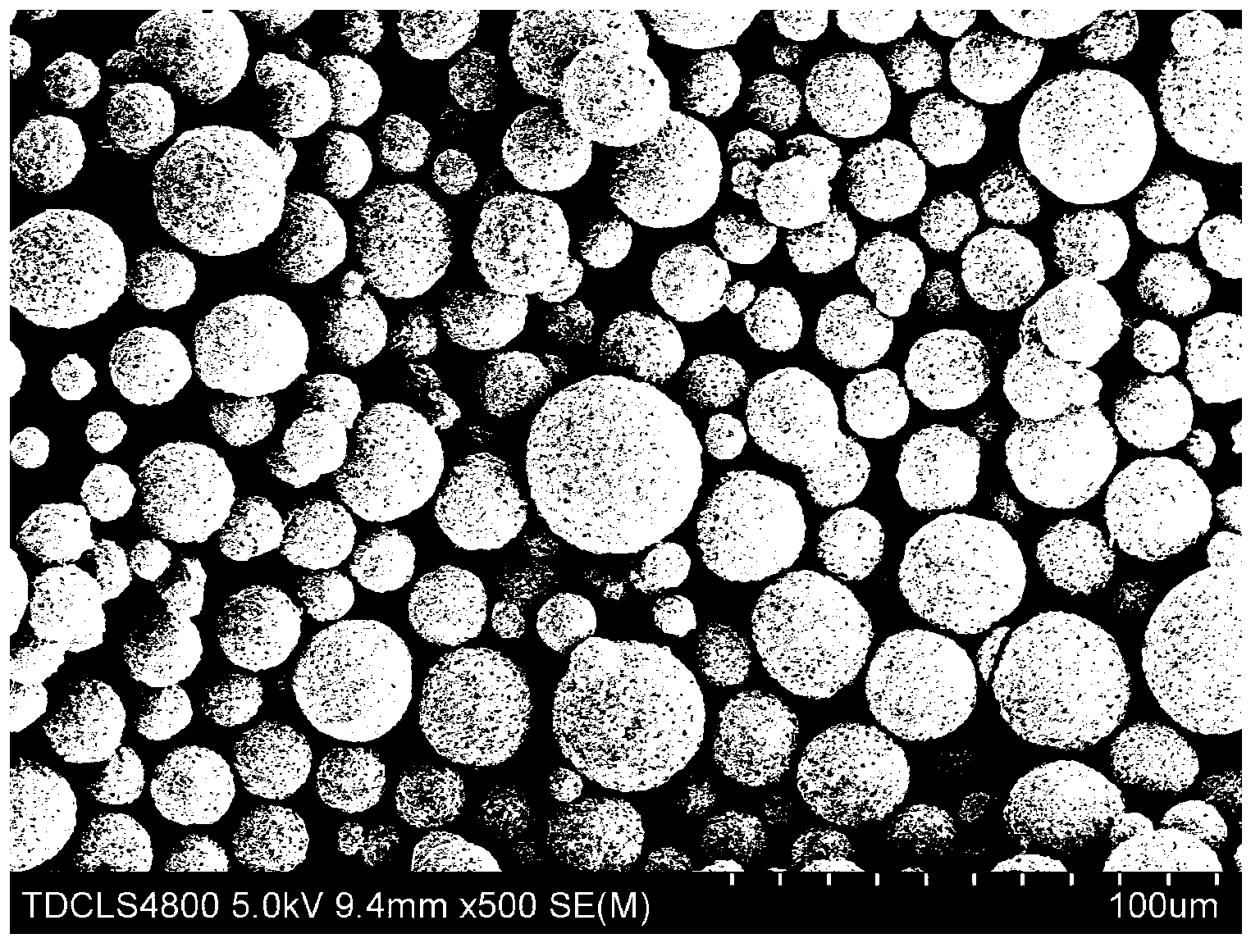

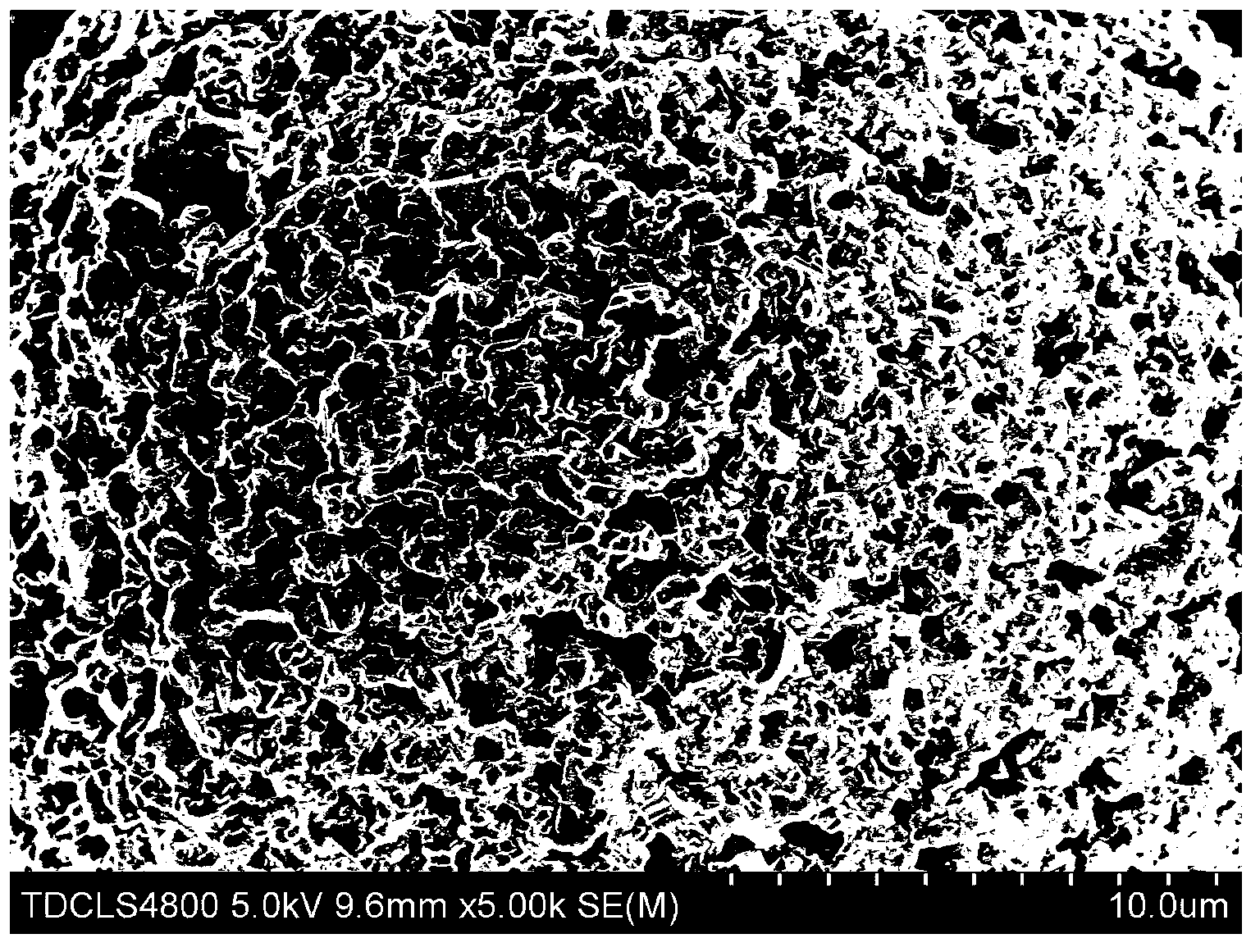

[0025] Using 88% WC and 12% Co mixture as raw material, in a liquid medium, first mix WC powder and Co powder evenly, then spray dry to form solid aggregate particles with Co as an organic binder, and finally conduct heat treatment . The heat treatment temperatures are 1000°C, 1200°C and 1600°C respectively. WC-12Co powders with WC grains of nanoscale (10nm≤d3 / h, propane pressure is 0.65MPa, propane gas flow is 1.35m 3 / h, the spraying distance is 250mm, the powder feeding gas is N 2 , the gas pressure is 0.6MPa, and the powder feeding speed is 2r / min. After spraying, the coating is cooled with compressed air (see Figure 3(b, c)) and the thickness is 300μm. The SEM microstructure of the coating is shown in Figure 3(c). In the prepared coating, nano WC grains account for about 12%, submicron WC grains account for about 22%, and micron WC grains account for about 66%. Finally, after testing, its strength is ≥ 70MPa and hardness is 1200HV 0.1 ~1300HV 0.1 , the fracture toug...

Embodiment 2

[0027]Using 88% WC and 12% Co mixture as raw material, in a liquid medium, firstly mix WC powder and Co powder evenly, then spray dry to form solid aggregate particles with Co as organic binder, and finally conduct heat treatment . The heat treatment temperatures are 1100°C, 1200°C and 1500°C respectively. The WC-12Co powders with WC grains in nanometer scale (10nm≤d3 / h, propane pressure is 0.65MPa, propane gas flow is 1.35m 3 / h, the spraying distance is 250mm, the powder feeding gas is N 2 , gas pressure 0.6MPa, powder feeding speed 2r / min. After spraying, use compressed air to cool the coating thickness to 350μm. In the prepared coating, nano WC grains account for about 16%, submicron WC grains account for about 27%, and micron WC grains account for about 57%. Finally, after testing, its strength is ≥ 65MPa, and its hardness is 1100HV 0.1 ~1250HV 0.1 , the fracture toughness measured by indentation method is 13.3±1.4MPa·m 1 / 2 . Its comprehensive mechanical properties ...

Embodiment 3

[0029] Using 88% WC and 12% Co mixture as raw material, in a liquid medium, firstly mix WC powder and Co powder evenly, then spray dry to form solid aggregate particles with Co as organic binder, and finally conduct heat treatment . The heat treatment temperatures are 1100°C, 1200°C and 1400°C respectively. The WC-12Co powders with WC grains in nanometer scale (10nm≤d3 / h, propane pressure is 0.65MPa, propane gas flow is 1.35m 3 / h, the spraying distance is 250mm, the powder feeding gas is N 2 , gas pressure 0.6MPa, powder feeding speed 2r / min. After spraying, use compressed air to cool the coating thickness to 320μm. In the prepared coating, nano WC grains account for about 12%, submicron WC grains account for about 22%, and micron WC grains account for about 66%. Finally, after testing, its strength is ≥ 66MPa, and its hardness is 1100HV 0.1 ~1250HV 0.1 , the fracture toughness measured by indentation method is 13.3±1.6MPa·m 1 / 2 . Its comprehensive mechanical properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com