High-toughness bainite wear-resistant steel suitable for liner plate of large semi-autogenous mill and preparation method of high-toughness bainite wear-resistant steel

A semi-autogenous mill, high-strength and toughness technology, applied in the field of wear-resistant steel, can solve the problems of increasing the difficulty of smelting, prone to segregation, high Mn content, etc., and achieve the effect of uniform hardness, uniform structure and composition, and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

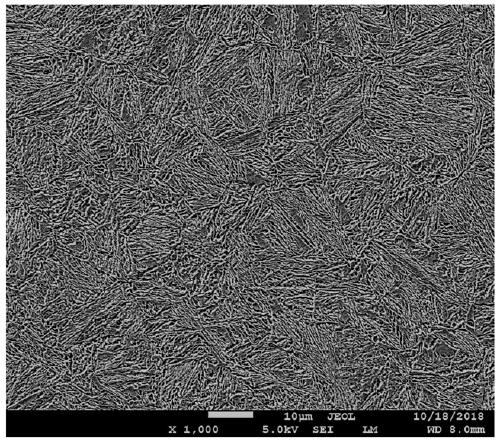

Image

Examples

Embodiment 1

[0042] 1. Melting: Melt high-quality steel scrap in an electric furnace, add ferrosilicon, ferrochrome, add electrolytic manganese, molybdenum, niobium, and recarburizer to adjust to the required composition, then transfer to a refining furnace for refining, use aluminum deoxidation during smelting, and Add rare earths to the vacuum degassing bag. Then it is cast into electrode rods, and electroslag remelting is carried out (diameter of electroslag ingot is 450mm). During electroslag remelting, ternary high-alkaline slag system is used for desulfurization and deoxidation, and then annealing process is used for electroslag ingots to eliminate casting stress.

[0043] The composition of the obtained electroslag ingot is 0.62% for C, 1.4% for Si, 1.4% for Mn, 1.7% for Cr, 0.3% for Mo, 0.03% for Nb, 0.1% for Cu, 0.2% for Ni, and 0.02% for Al , P is 0.013%, S is 0.008%, RE is 0.1%, and N is 0.01%;

[0044] 2. Forging: heating temperature 1150-1200°C, initial forging temperature 11...

Embodiment 2

[0048] 1. Melting: Melt high-quality steel scrap in an electric furnace, add ferrosilicon, ferrochrome, add electrolytic manganese, molybdenum, niobium, and recarburizer to adjust to the required composition, then transfer to a refining furnace for refining, use aluminum deoxidation during smelting, and Add rare earths to the vacuum degassing bag. Then it is cast into electrode rods, and electroslag remelting is carried out (diameter of electroslag ingot is 450mm). During electroslag remelting, ternary high-alkaline slag system is used for desulfurization and deoxidation, and then annealing process is used for electroslag ingots to eliminate casting stress.

[0049] The composition of the obtained electroslag ingot is 0.58% of C, 1.5% of Si, 1.3% of Mn, 1.7% of Cr, 0.7% of Mo, 0.03% of Nb, 0.2% of Cu, 0.2% of Ni, 0.015% of Al, P 0.015% for S, 0.01% for S, 0.05% for RE, and 0.008% for N;

[0050] 2. Forging: Heating temperature 1150-1200°C, initial forging temperature 1150°C, ...

Embodiment 3

[0054] 1. Melting: Melt high-quality steel scrap in an electric furnace, add ferrosilicon, ferrochrome, add electrolytic manganese, molybdenum, niobium, and recarburizer to adjust to the required composition, then transfer to a refining furnace for refining, use aluminum deoxidation during smelting, and Add rare earths to the vacuum degassing bag. Then it is cast into electrode rods, and electroslag remelting is carried out (diameter of electroslag ingot is 450mm). During electroslag remelting, ternary high-alkaline slag system is used for desulfurization and deoxidation, and then annealing process is used for electroslag ingots to eliminate casting stress.

[0055] The composition of the obtained electroslag ingot is 0.7% for C, 1.4% for Si, 1.1% for Mn, 2.5% for Cr, 0.5% for Mo, 0.03% for Nb, 0.3% for Cu, 0.3% for Ni, and 0.03% for Al , P is 0.01%, S is 0.004%, RE is 0.02%, and N is 0.015%;

[0056] 2. Forging: Heating temperature 1150-1200°C, initial forging temperature 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com