Preparation method for spherical nano-silicon dioxide

A technology of nano silicon dioxide and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problem of low yield of nano silicon dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

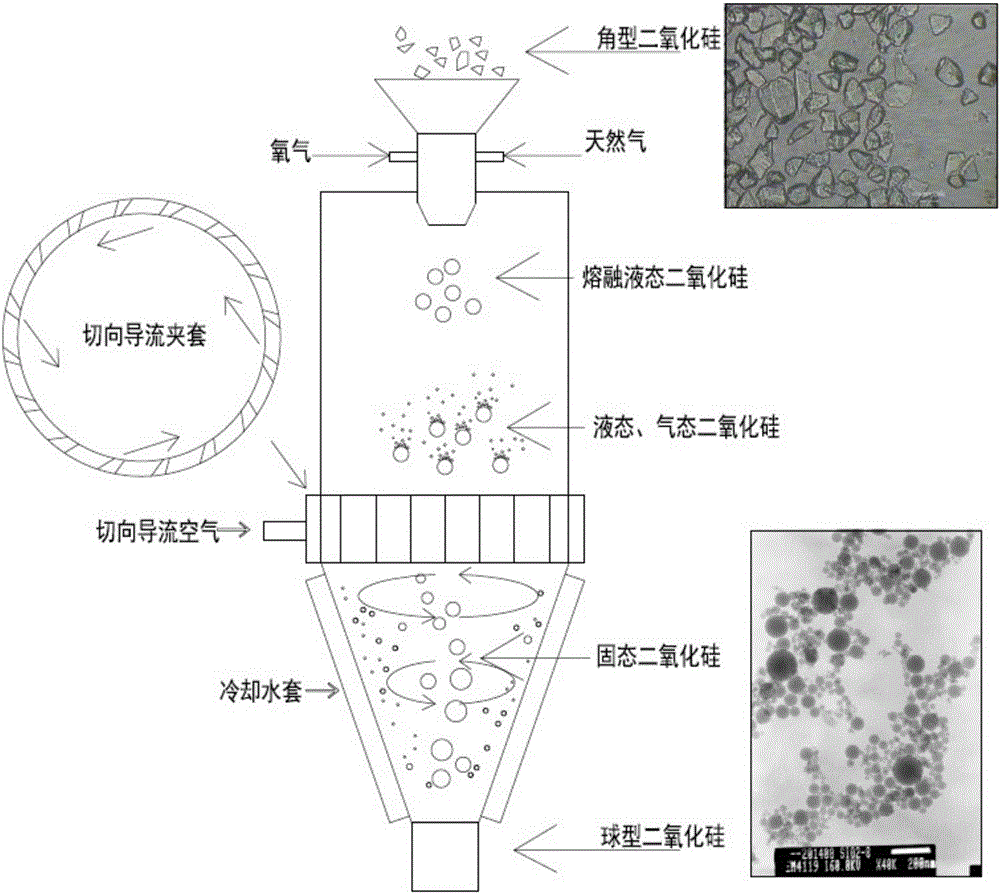

Method used

Image

Examples

Embodiment 1

[0023] S1, provide natural quartz powder with a particle size of 10 μm.

[0024] S2, using natural gas and oxygen to generate flames to form a flame field, along the conveying direction of natural quartz powder, the flame field includes a first flame field with a temperature between 1700-2000°C and a second flame field with a temperature between 2300-2600°C , the natural quartz powder is vertically injected into the flame field and melted in the first flame field to form molten liquid quartz particles, and the molten liquid quartz particles are in the high temperature condition exceeding the gasification point temperature and the high-speed downward high temperature in the second flame field Under the action of air flow, the surface of molten liquid quartz particles evaporates to form nanoscale vapors. Wherein, the length of the first flame field is 2m, and the length of the second flame field is 0.5m.

[0025] S3, rapid cooling and shaping. 2000m 3 / h of air is used for va...

Embodiment 2

[0029] S1, provide fused silica with a particle size of 5 μm.

[0030] S2, using natural gas and oxygen to generate a flame to form a flame field, along the conveying direction of the silica particles, the flame field includes a first flame field with a temperature between 1700-2000°C and a second flame with a temperature between 2300-2500°C Silica particles are injected vertically into the flame field and melted into liquid spherical particles in the first flame field. The molten liquid quartz particles are in the high temperature condition exceeding the gasification point temperature and the high-speed downward motion in the second flame field. Under the action of high-temperature air flow, the surface of molten liquid quartz particles evaporates to form nanoscale vapors. Wherein, the length of the first flame field is 3m, and the length of the second flame field is 1.5m.

[0031] S3, rapid cooling and shaping. 3000m 3 / h of air is used for vapor dispersion, cooling, and ...

Embodiment 3

[0035] S1, providing silica particles with a particle size of 3 μm.

[0036] S2, using natural gas and oxygen to generate flames to form a flame field, along the conveying direction of silica particles, the flame field includes a first flame field with a temperature between 1700-2000°C and a second flame with a temperature between 2300-2600°C In the second flame field, the silicon dioxide particles are sprayed vertically into the flame field and melted to form spherical liquid quartz particles in the first flame field. Under the action of high-temperature air flow, the surface of molten liquid quartz particles evaporates to form nano-scale vapors. Wherein, the length of the first flame field is 3m, and the length of the second flame field is 1.2m.

[0037] S3, rapid cooling and shaping. 2500m 3 / h of air is used for vapor dispersion, cooling, and diversion. In addition, cooling water flowing through the jacketed furnace walls is used for cooling. To ensure that the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com