Film with oil-water separation tapered needle array having underwater oleophilic property on surface as well as preparation method and use of film

An oil-water separation and conical needle technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of complex process, accelerated progress, separation, etc., and achieve the effects of low preparation cost, easy cleaning and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] ⑴Heat and press the high-density polyethylene particles at 180℃ to form high-density polyethylene sheets with a smooth surface and thickness of about 1-2mm, cut them into 2cm×2cm size, clean them, and dry them at room temperature;

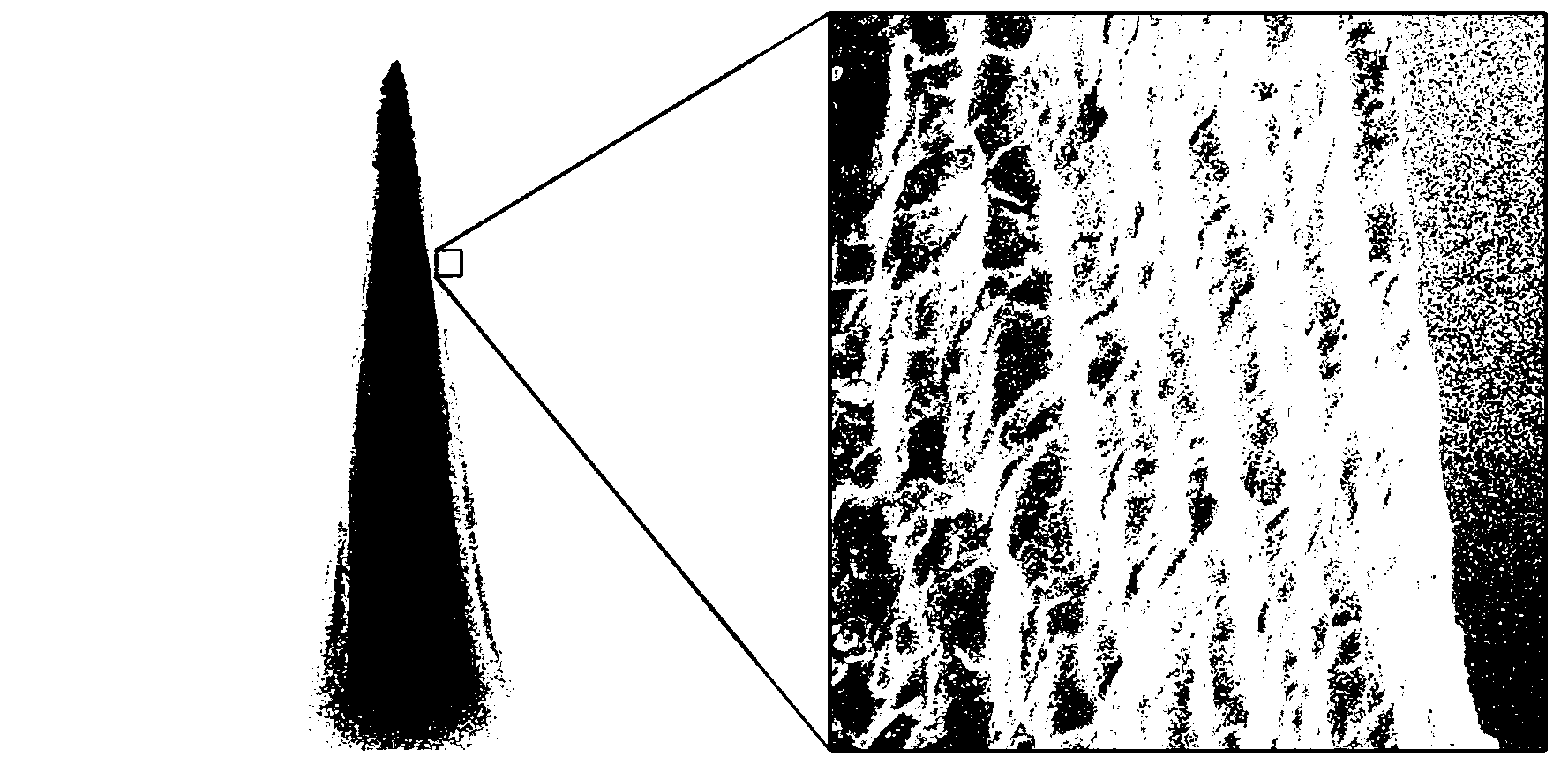

[0036] ⑵Use 2000 # Sandpaper, sanding from the root to the tip of the tapered stainless steel needle, sand the surface of the tapered stainless steel needle to form a ridge-like rough structure that is compatible with the edges and corners of the sand on the sandpaper, clean it, and dry at room temperature;

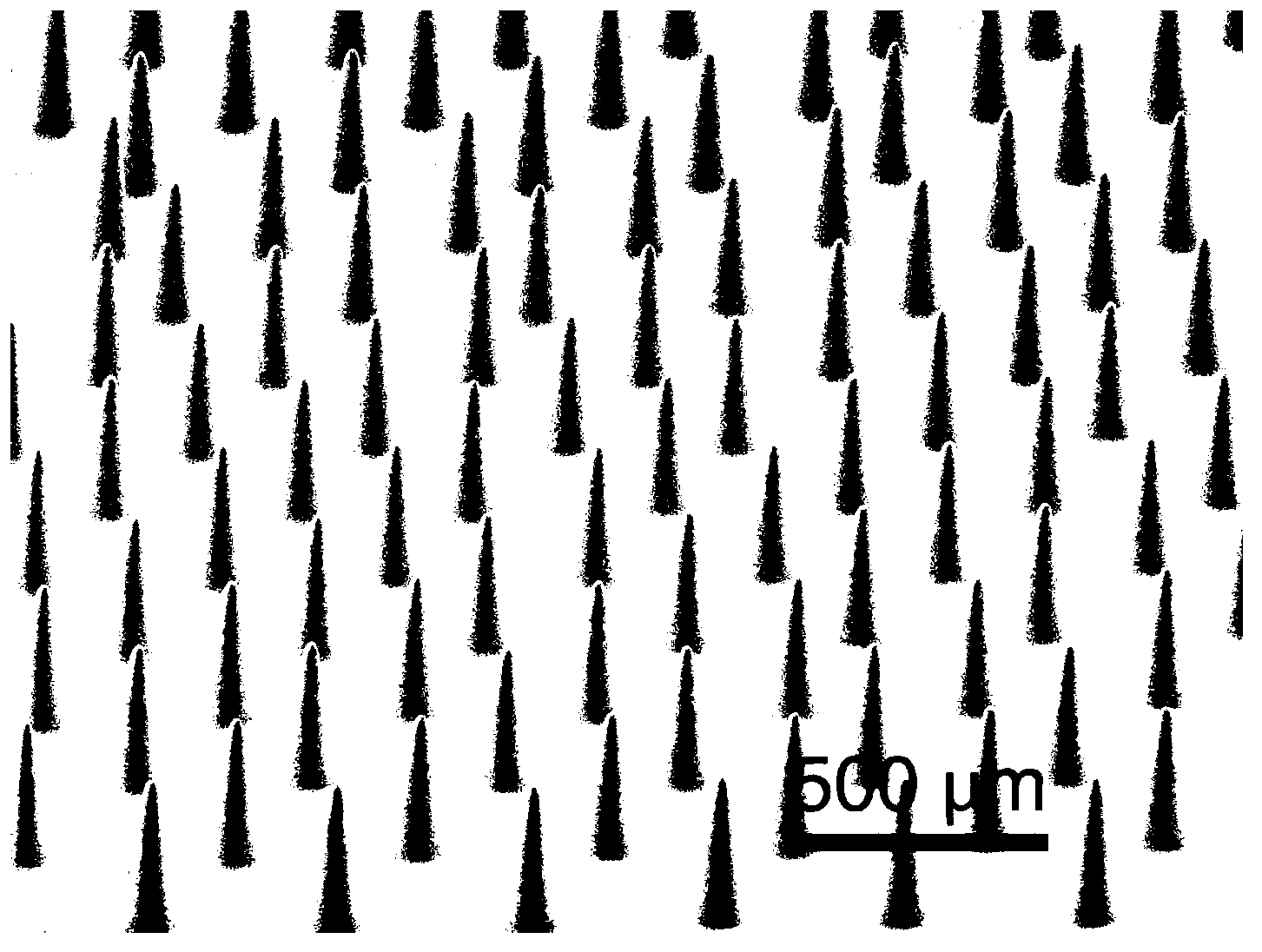

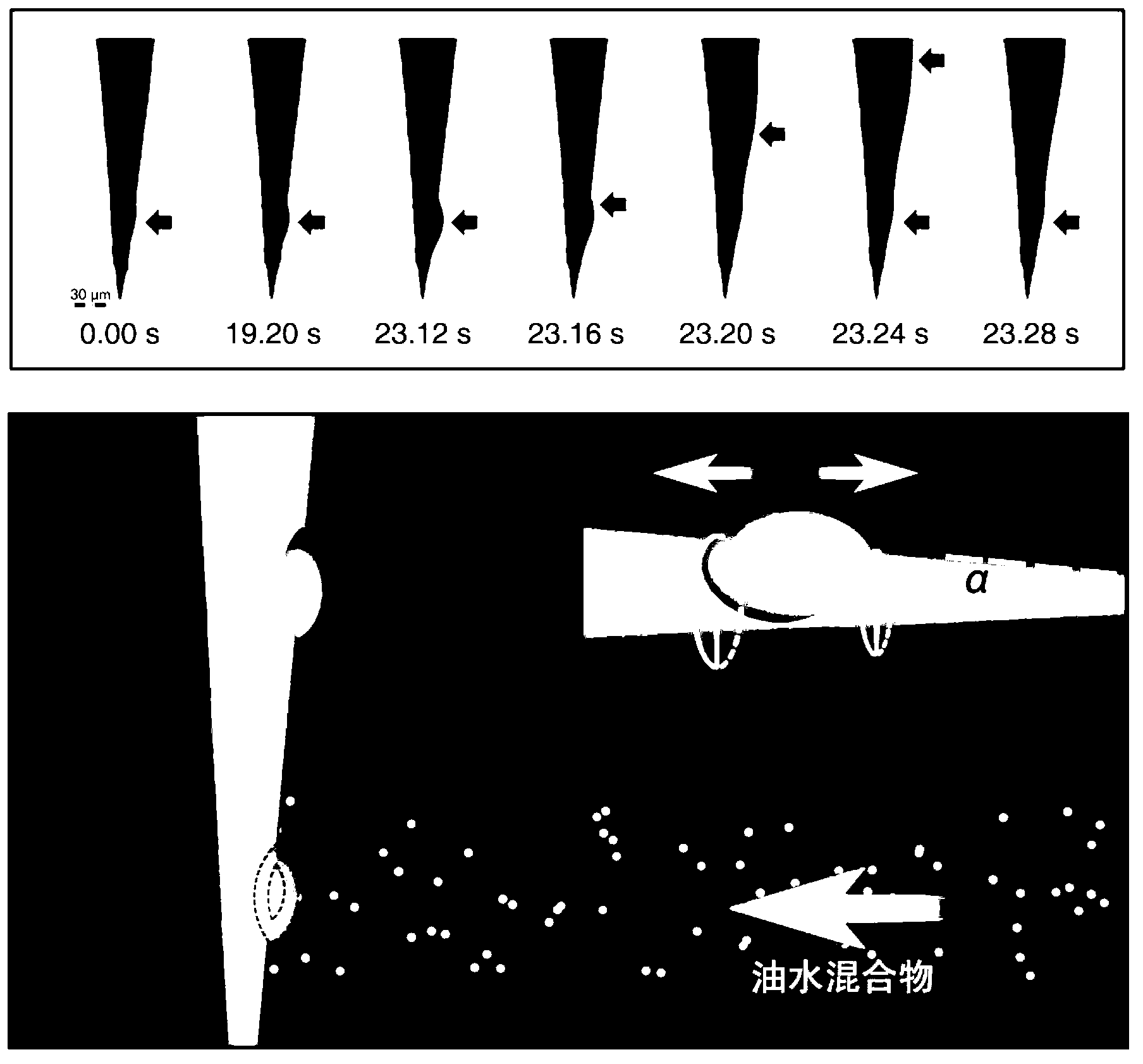

[0037] (3) Place the high-density polyethylene sheet obtained in step (1) and the tapered stainless steel needle with a ridge-like rough structure on the surface obtained in step (2) in the xyz control system of the dispenser (Nordson EFD-PicoDot, USA), and use the dispensing The machine makes the needle tips of the tapered stainless steel needles perforate arrayed on the high-density polyethylene sheet to obtain a tapered pinhole array on th...

Embodiment 2

[0042] ⑴Heat and press the high-density polyethylene particles at 180℃ to form high-density polyethylene sheets with a smooth surface and thickness of about 1-2mm, cut them into 2cm×2cm size, clean them, and dry them at room temperature;

[0043] ⑵Use 100 # Sandpaper, sanding from the root to the tip of the tapered stainless steel needle, sand the surface of the tapered stainless steel needle to form a ridge-like rough structure that is compatible with the edges and corners of the sand on the sandpaper, clean it, and dry at room temperature;

[0044] (3) Place the high-density polyethylene sheet obtained in step (1) and the tapered stainless steel needle with a ridge-like rough structure on the surface obtained in step (2) in the xyz control system of the dispenser (Nordson EFD-PicoDot, USA), and use the dispensing The machine makes the needle tips of the tapered stainless steel needles perforate arrayed on the high-density polyethylene sheet to obtain a tapered pinhole array on the...

Embodiment 3

[0049] ⑴Heat and press the high-density polyethylene particles at 180℃ to form high-density polyethylene sheets with a smooth surface and thickness of about 1-2mm, cut them into 2cm×2cm size, clean them, and dry them at room temperature;

[0050] ⑵Use 800 # Sandpaper, sanding from the root to the tip of the tapered stainless steel needle, sand the surface of the tapered stainless steel needle to form a ridge-like rough structure that is compatible with the edges and corners of the sand on the sandpaper, clean it, and dry at room temperature;

[0051] (3) Place the high-density polyethylene sheet obtained in step (1) and the tapered stainless steel needle with a ridge-like rough structure on the surface obtained in step (2) in the xyz control system of the dispenser (Nordson EFD-PicoDot, USA), and use the dispensing The machine makes the needle tips of the tapered stainless steel needles perforate arrayed on the high-density polyethylene sheet to obtain a tapered pinhole array on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com