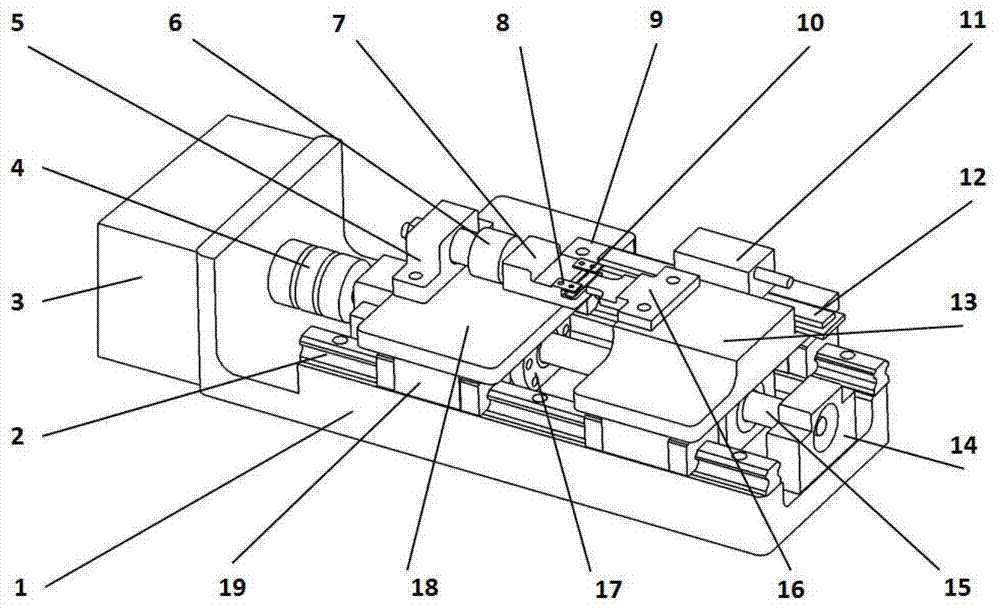

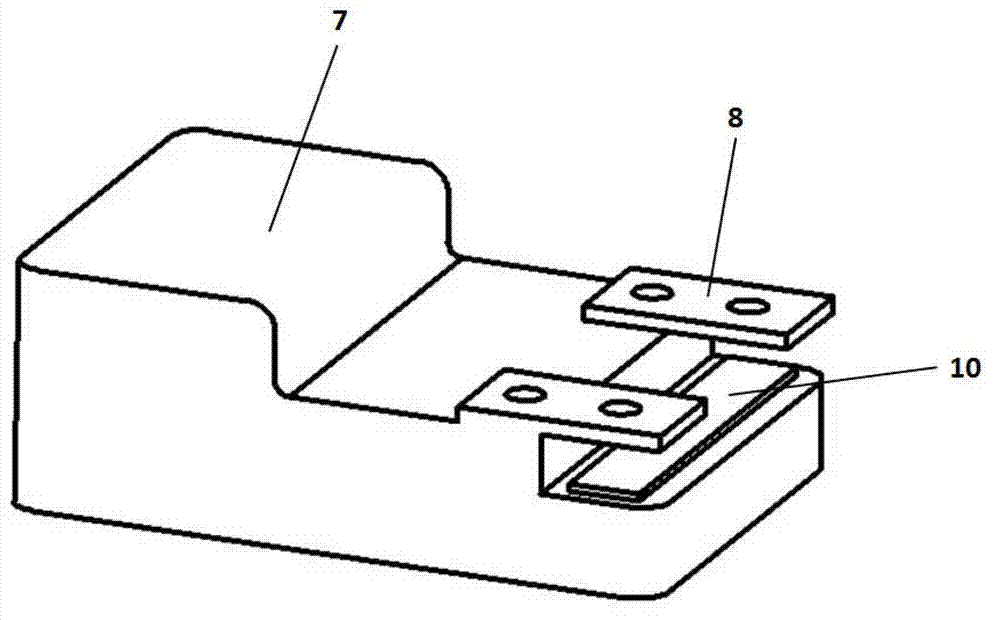

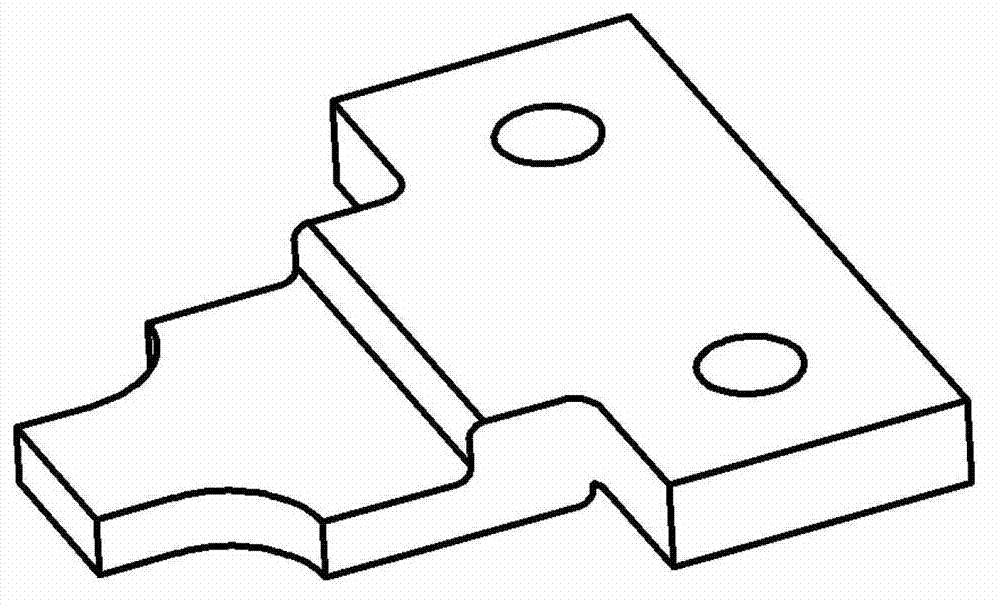

Mechanical-thermal composite in-situ loading system

A thermal compounding and in-situ loading technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as transverse cracks, film debonding and structural failure, and achieve uniform heating, simple and reliable loading methods, and high performance. The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] use figure 1 The setup shown is an example of an experiment with a 150 nm thick aluminum film deposited on a plexiglass substrate. Base material size: length 8mm, width 5mm, height 3mm, observed with 1000 times optical microscope. Pic 4-1 It is the buckling topography of the film surface under the condition of the sample at room temperature and the compressive load of 160N, Figure 4-2 It is the buckling morphology diagram of the sample after the compressive load is gradually increased to 200N, and it has undergone 10 times of thermal cycle loading from room temperature 27°C to 37°C. From Pic 4-1 , 4-2 It can be seen from the two experimental images that the observation area in the field of view of the film substrate structure does not move out of the field of view of the microscope under compressive load and thermal cycle load. It shows that the device can effectively realize in-situ observation. In the process of increasing load and thermal cycle loading, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com