A method for preparing in-situ stretched samples for transmission electron microscopy

A technology of in-situ stretching and transmission electron microscopy, applied in the preparation of test samples, etc., can solve the problems of low yield of sample preparation, cracking of processing performance, inability to prepare samples, etc., and achieve the effect of wide adaptability and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] A method for preparing a transmission electron microscope in-situ stretched sample, comprising the following steps:

[0053] 1. Stick the bulk sample on the sample stage with conductive carbon glue, and use the altimeter to ensure that the surface height of the sample does not exceed the height of the altimeter, and then send the sample into the FIB sample chamber.

[0054] 2. Adjust the focal length on the block sample to eliminate astigmatism.

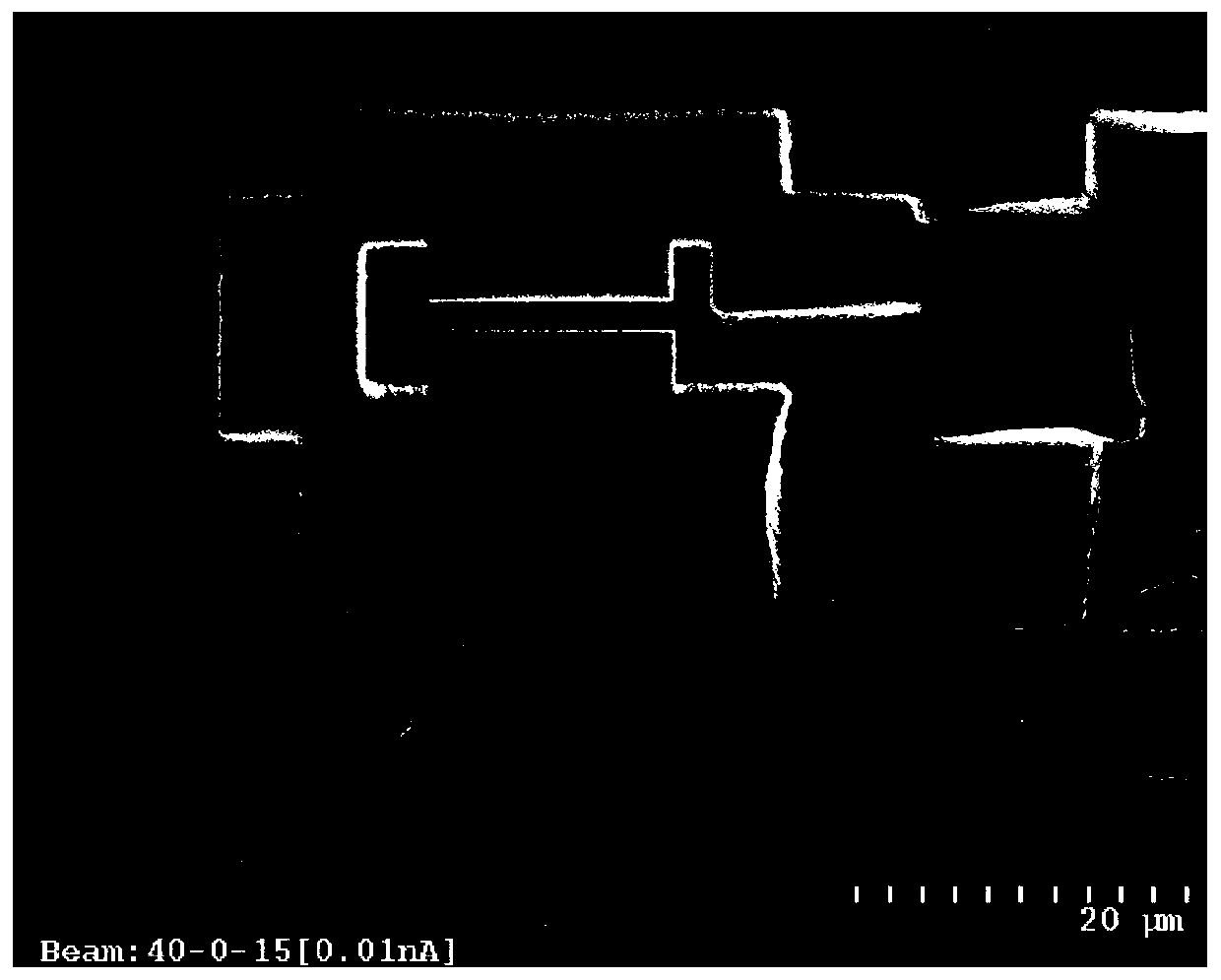

[0055] 3. Raise the block sample to a working distance of 6.5 mm, center the optical path, select the target area, and dig an I-shaped rough blank with thick ends and thin beams in the middle, such as figure 1 As shown, one end of the rough billet is connected with the block sample, and it will not be cut off temporarily, such as figure 2 shown.

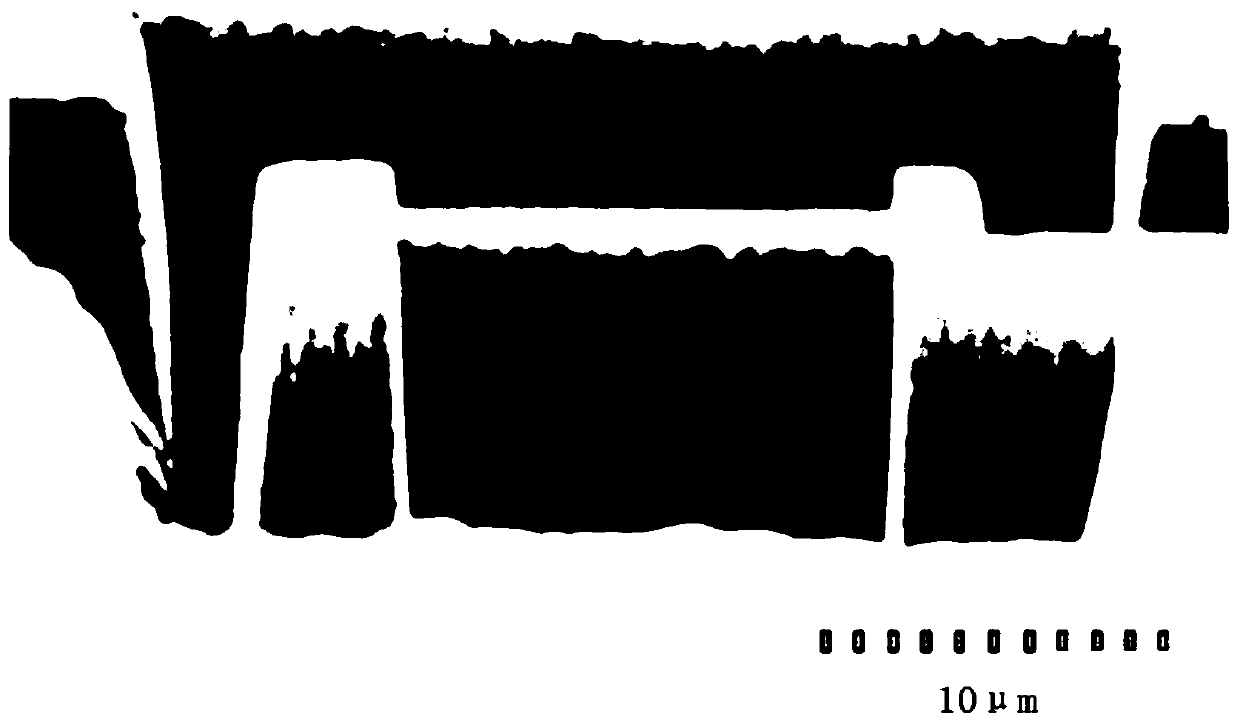

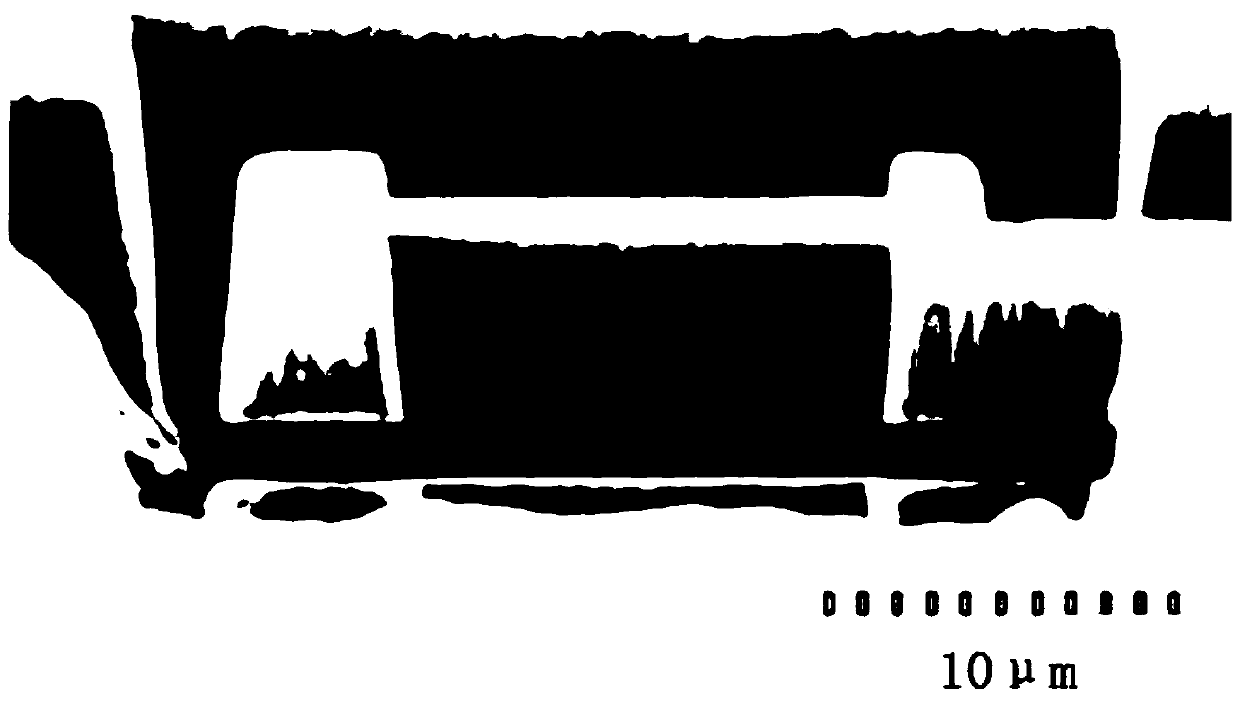

[0056] 4. Lower the sample to a working distance of 15 mm and tilt at an angle of 60 degrees to cut off the bottom of the rough blank, such as image 3 shown.

[0057] 5. Raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com