Heating device for micro-area controllable nano functional material synthesis

A nano-functional, heating device technology, applied in the direction of single crystal growth, chemical instruments and methods, from condensed steam, etc., can solve the problems of single synthesis method, large volume, poor controllability, etc., and achieve small synthesis device, simple and compact structure , Ease of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

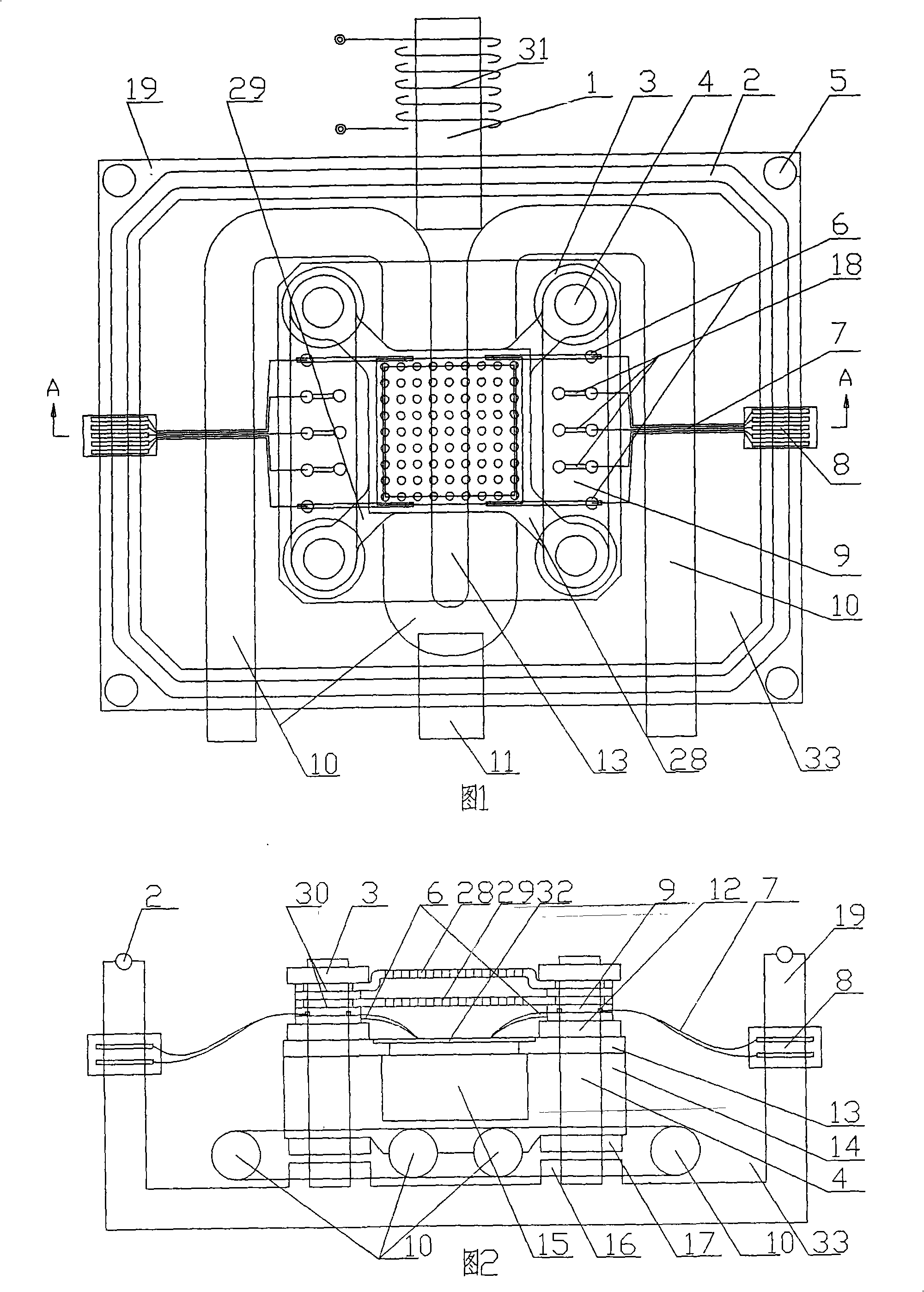

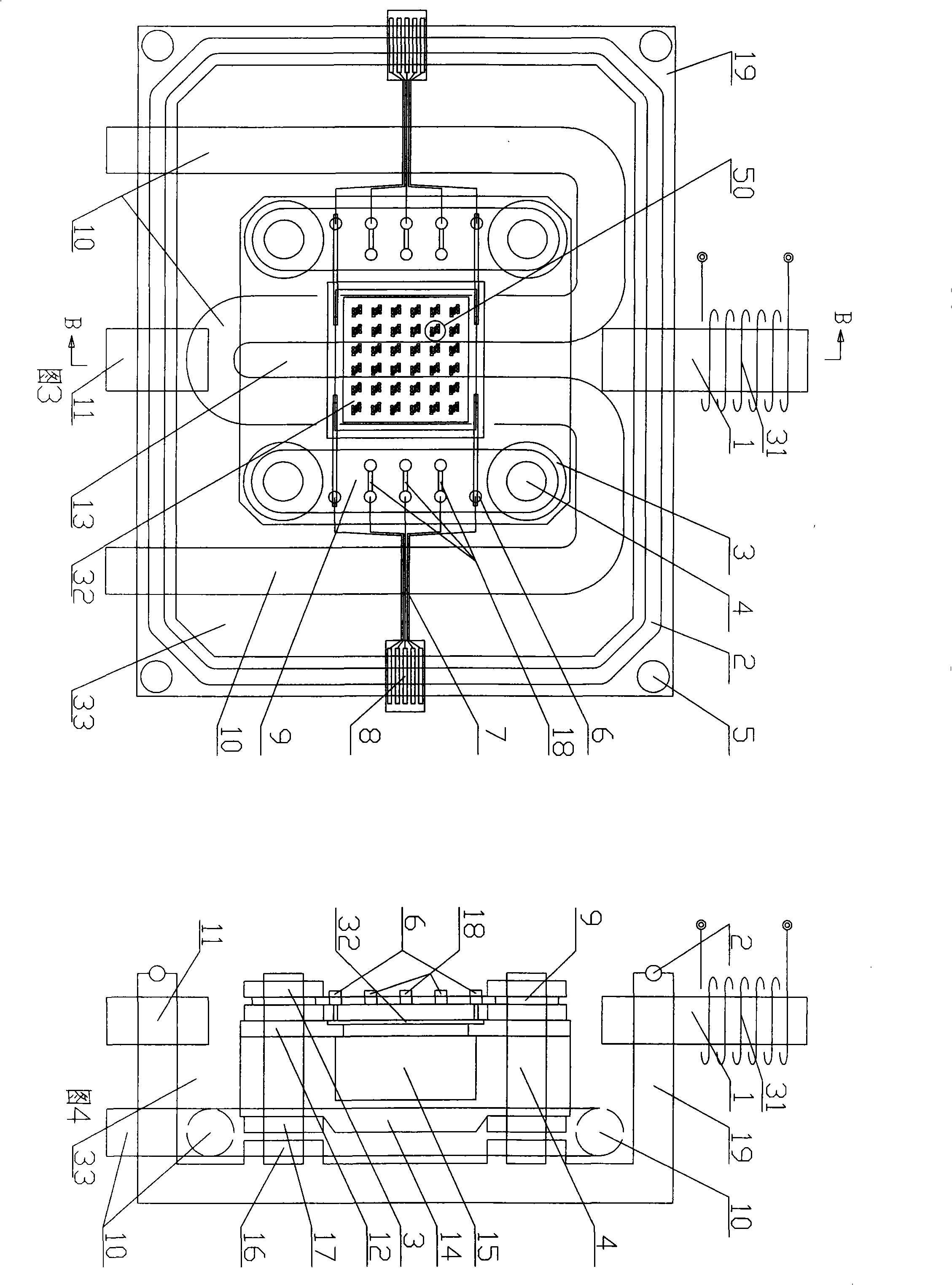

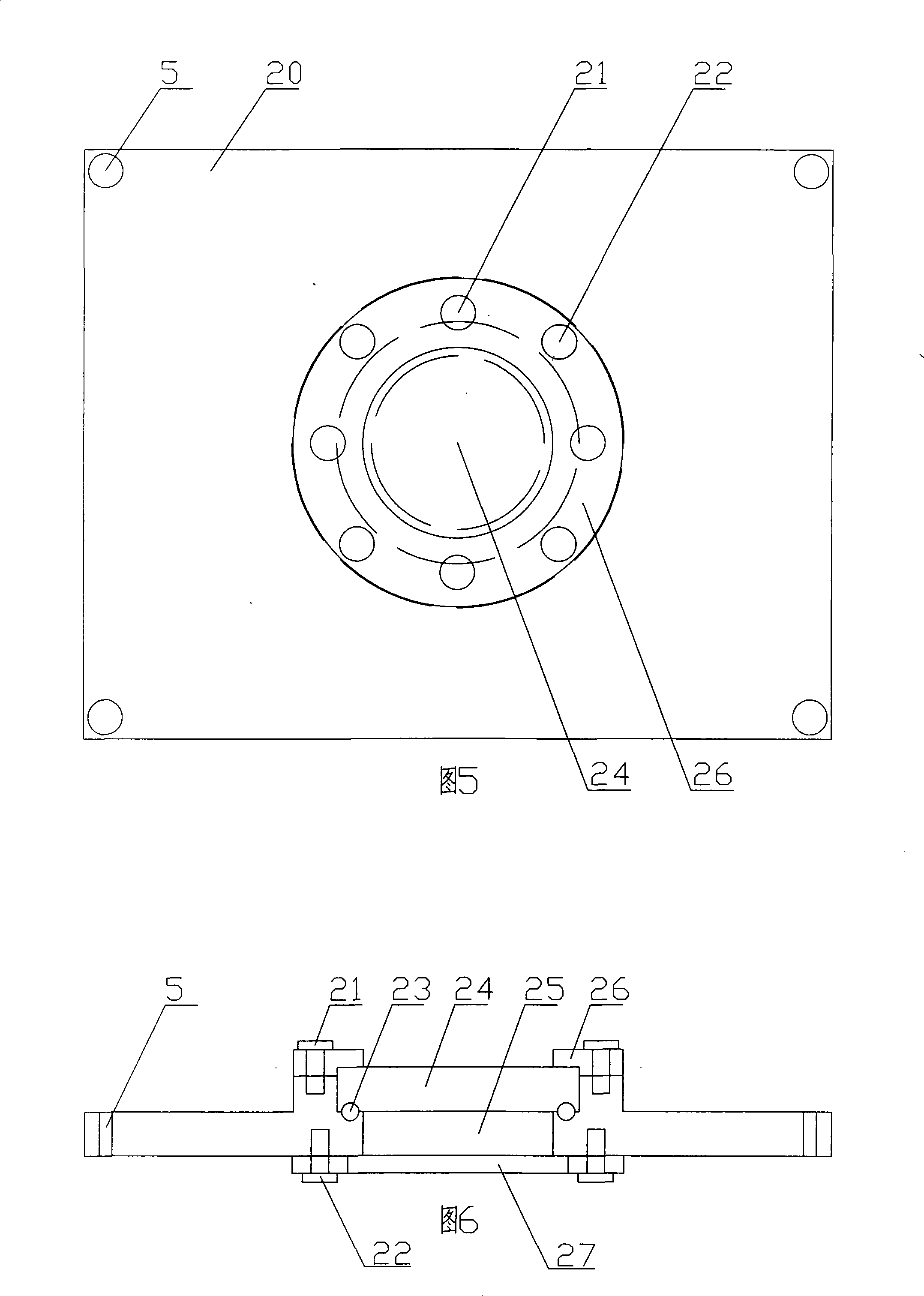

[0036] Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention comprises rectangular box body 19 and lid 20; The length, width and height of rectangular box body 19 are respectively 86 millimeters, 68 millimeters, 30 millimeters.

[0037] The corresponding two side walls of the rectangular box body 19 are respectively provided with an air inlet interface 1 and an air outlet interface 11, and the corresponding other two side walls are respectively provided with a wire interface 8; There is an air inlet coil 31 that is 3-5 centimeters (cm) long.

[0038] A rectangular heat dissipation base 14 is fixedly installed in the middle part of the box body 19 through four columns 4 on four corners, and the lower end of the column 4 is fixedly installed in the base positioning hole 16 through the lower positioning nut 7; the middle part of the heat dissipation base 14 is the lower Concave heat dissipation cavity 15; the length, width and height of the rectangular heat dissip...

Embodiment 2

[0049] Electromagnet 39 is loaded into the cooling cavity 15 and the observation window hole 25 of the upper cover. Others are with embodiment 1.

[0050] Close the gas path air valve 38 and the molecular pump valve 43, open the mechanical pump valve 41 and the mechanical pump 42, and vacuumize the working chamber 33. Observe the indication of the barometer 40 in the working chamber, and when it drops to 0Pa, close the valve 41 of the mechanical pump, open the valve 43 of the molecular pump, and the valve 44 of the molecular pump to continue vacuuming the working chamber 33 until the reaction condition is reached. The gas path valve 38 is opened, and the reaction gas A enters from the gas path interface 36 , and flows into the working chamber 33 after the gas flow meter 37 adjusts the gas flow.

[0051] A constant DC voltage of 130V-220V is applied between the upper plate 28 and the lower plate 29 to promote ionization and activation of the reactive gas. Apply current to the...

Embodiment 3

[0056] A set of wires is used to connect the probes 6 to the resistance lines 35 of the circuits 50 in the odd columns on the silicon chip 32 , and another group of wires is used to connect the probes 6 to the resistance lines 35 of the circuits 50 in the even columns on the silicon chip 32 . Connect the upper plate 28 and the lower plate 29 with the wire connector 8 and apply positive and negative DC voltages respectively. Heat radiation base cavity 15, loam cake cavity 25 pack electromagnet 39, and connect it with wire connector 8 with silver glue, electric wire.

[0057] Others are with embodiment 1.

[0058] Close the gas path air valve 38 and the molecular pump valve 46, open the mechanical pump valve 41 and the mechanical pump 42, and vacuumize the working chamber 33. Observe the indication of the barometer 40 in the working chamber, and when it drops to 0Pa, close the valve 41 of the mechanical pump, open the valve 43 of the molecular pump, and the valve 44 of the mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com