Device and method for in-situ observation of domain structure of ferroelectric material before and after electric field action

A ferroelectric material and electric domain technology, which is applied in the field of devices for in-situ observation of the electric domain structure of ferroelectric materials before and after the action of an electric field, can solve the problem of low voltage, inability to apply continuous pulse voltage, and inability to observe changes in electric domain structure, etc. problem, to achieve the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

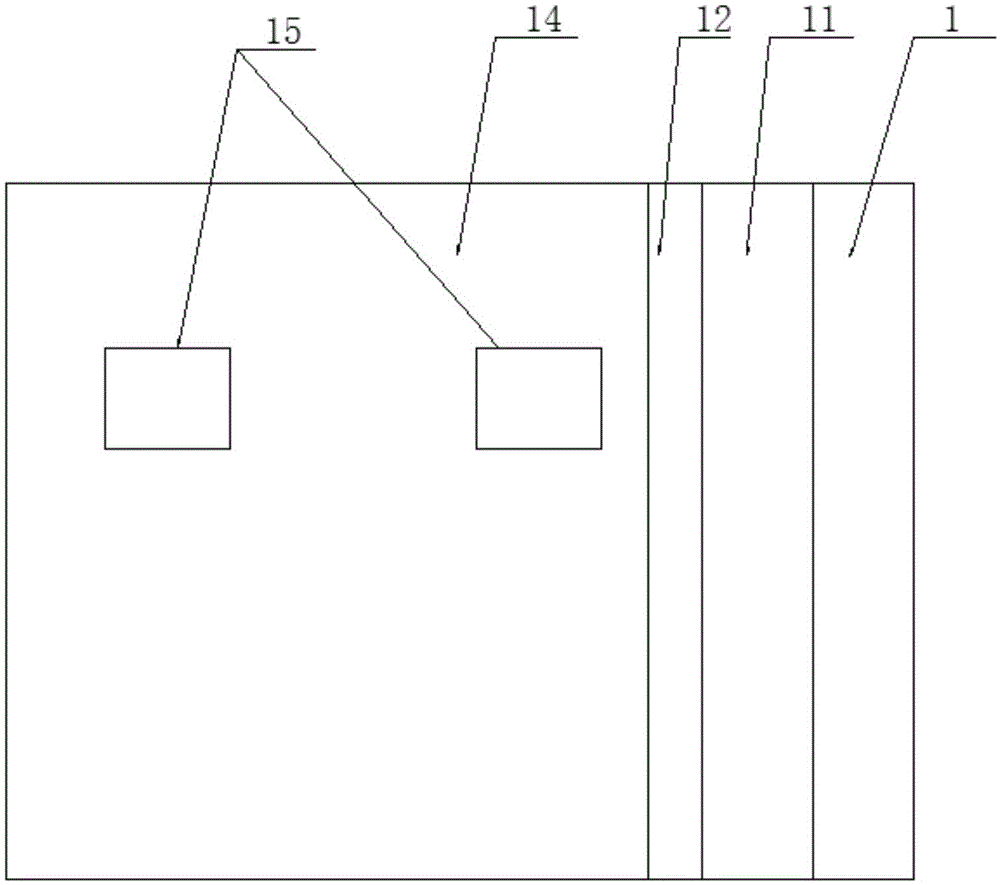

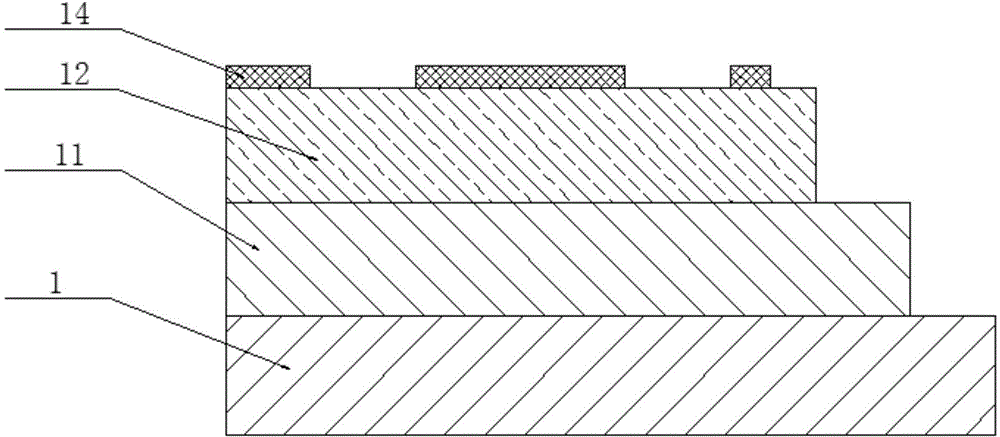

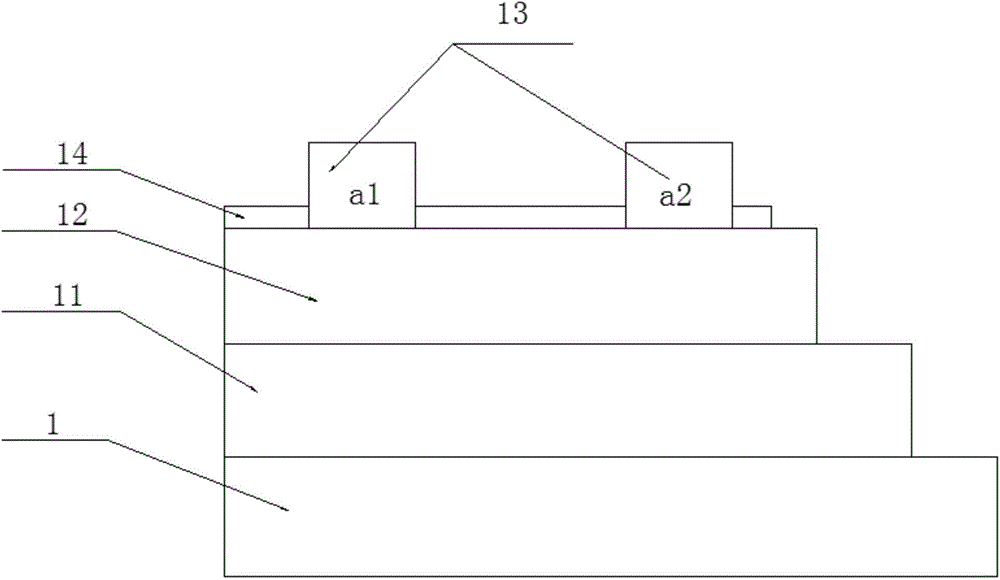

[0035] Such as figure 1 , figure 2 with image 3 As shown, a device for in situ observation of the domain structure of ferroelectric materials before and after an electric field is applied, including:

[0036] a substrate 1;

[0037] The lower electrode 11 is grown on the substrate 1;

[0038] a ferroelectric thin film 12 grown on the lower electrode 11;

[0039] An insulating layer 14 is grown on the ferroelectric thin film 12, and at least one electrode hole 15 is arranged on the insulating layer 14; when the number of electrode holes 15 provided is more than one, each electrode hole 15 is numbered or marked to distinguish, so as not to Observation is confusing, and when one electrode hole is damaged, other electrode holes can be observed, which improves the utilization rate of the device.

[0040] The upper electrode 13 is arranged in cooperation with the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com