Lithium-ion battery diaphragm and preparation method thereof

A technology for lithium-ion batteries and diaphragms, applied in the field of lithium-ion battery diaphragms and their preparation, can solve the problems of difficult electrolyte adsorption and heat shrinkage resistance of battery diaphragms, and achieve improved overall performance, improved heat shrinkage resistance, and enhanced The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

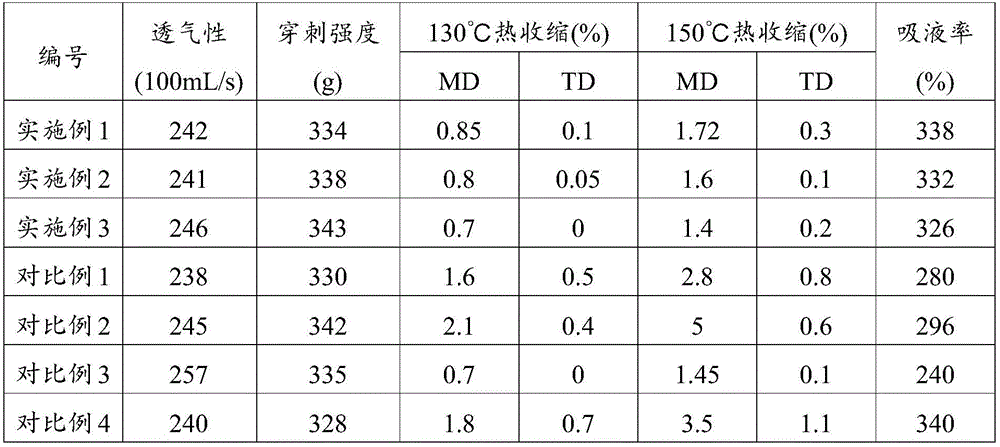

Embodiment 1

[0027] In this example, irregular-shaped alumina with a D50 of 600nm and flaky alumina with a D50 of 100nm are used to prepare a battery separator from two types of inorganic particles; the irregular-shaped alumina accounts for 40% of the total weight of the inorganic particles, and the sheet Granular alumina accounts for 60% of the total weight of the inorganic particles. The base membrane of this example is a high-density polypropylene microporous membrane with a thickness of 16 microns and a pore diameter of 30-35 nm.

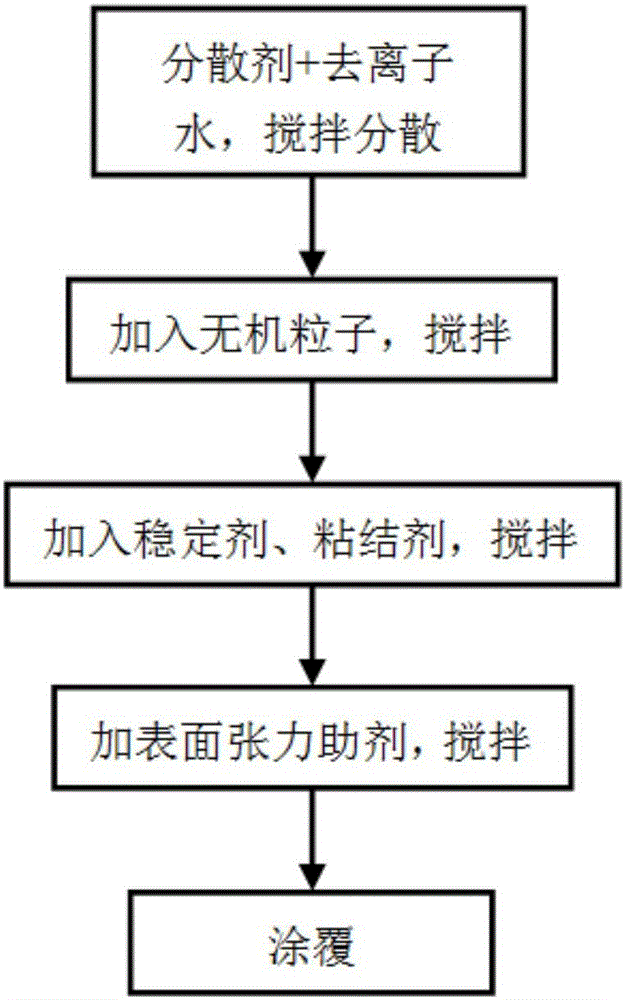

[0028] The specific preparation method of the battery separator in this example is as follows:

[0029] (1) Pour 0.3% of the total weight of the water-based slurry into the dispersant polyoxyethylene ether and water into the mixing tank, stir and mix for 30 minutes, and disperse by revolution at 60 RPM;

[0030] (2) Add 40% of the total weight of the water-based slurry to the inorganic particles, stir and mix for 2 hours, 60RPM revolution, 1200RPM rotation ...

Embodiment 2

[0035] In this example, flaky alumina with a D50 of 600nm and ellipsoidal alumina with a D50 of 100nm are used to prepare battery separators. The flaky alumina accounts for 40% of the total weight of the inorganic particles, and the ellipsoidal alumina Aluminum accounts for 60% of the total weight of the inorganic particles. All the other are the same as the first embodiment.

Embodiment 3

[0037] In this example, ellipsoidal alumina with a D50 of 400nm and irregular alumina with a D50 of 100nm are used to prepare battery separators. The ellipsoidal alumina accounts for 40% of the total weight of the inorganic particles, and the irregular Formed alumina accounts for 60% of the total weight of the inorganic particles. All the other are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com