A separator, its preparation method and an electrochemical device comprising the separator

A technology of isolation film and oxide, which is applied in the field of energy storage, can solve problems such as surface cracking and aging of ceramic layers, easy safety problems, and ceramic particle shedding, so as to improve interface wettability, avoid mechanical strength reduction, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] According to the preparation method of the isolation film of the second aspect of the embodiment of the present application, it at least includes the following steps:

[0032] providing the substrate, the substrate being a porous substrate; and

[0033] A layer of the inorganic layer is formed on the surface of the substrate and in the pores by a vapor deposition method to obtain the isolation film, wherein the thickness of the inorganic layer is 20 nm to 2000 nm, and the mass M1 of the inorganic layer is equal to that of the substrate. The ratio M1 / M2 of the mass M2 satisfies 0.05≤M1 / M2≤7.5, and the interfacial peel force between the inorganic layer and the substrate is not less than 30N / m.

[0034] The inorganic layer formed by vapor deposition method can not only be deposited on the surface of the substrate, but also can be further deposited on the inner wall of the hole of the substrate. With the increase of the coating rate of the inorganic layer on the substrate, ...

Embodiment

[0054] The lithium-ion secondary battery is prepared by the above method. Specifically, the plasma-assisted thermal evaporation deposition technology is used to prepare an inorganic layer with certain parameters on the upper and lower surfaces of the porous substrate by vapor deposition.

[0055] The specific process parameters are: the target is metal aluminum (it can also be doped with other elements, such as Si), and the vacuum degree of the deposition chamber is less than 1×10 -3 Pa, the heating current is 190A, the oxygen flow rate is 300sccm, the plasma power is about 300W to activate the reaction gas, and the process time is 5min.

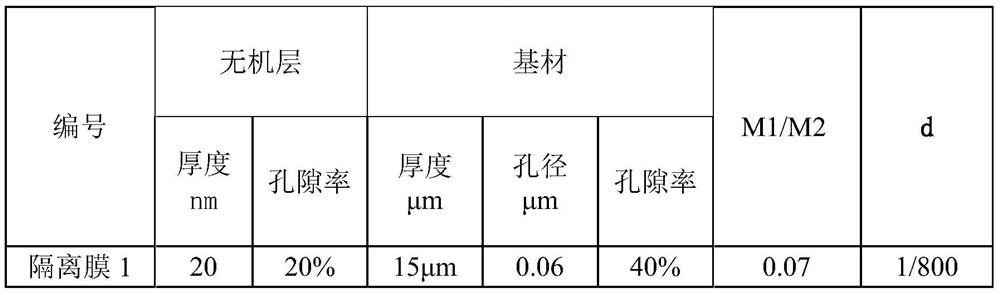

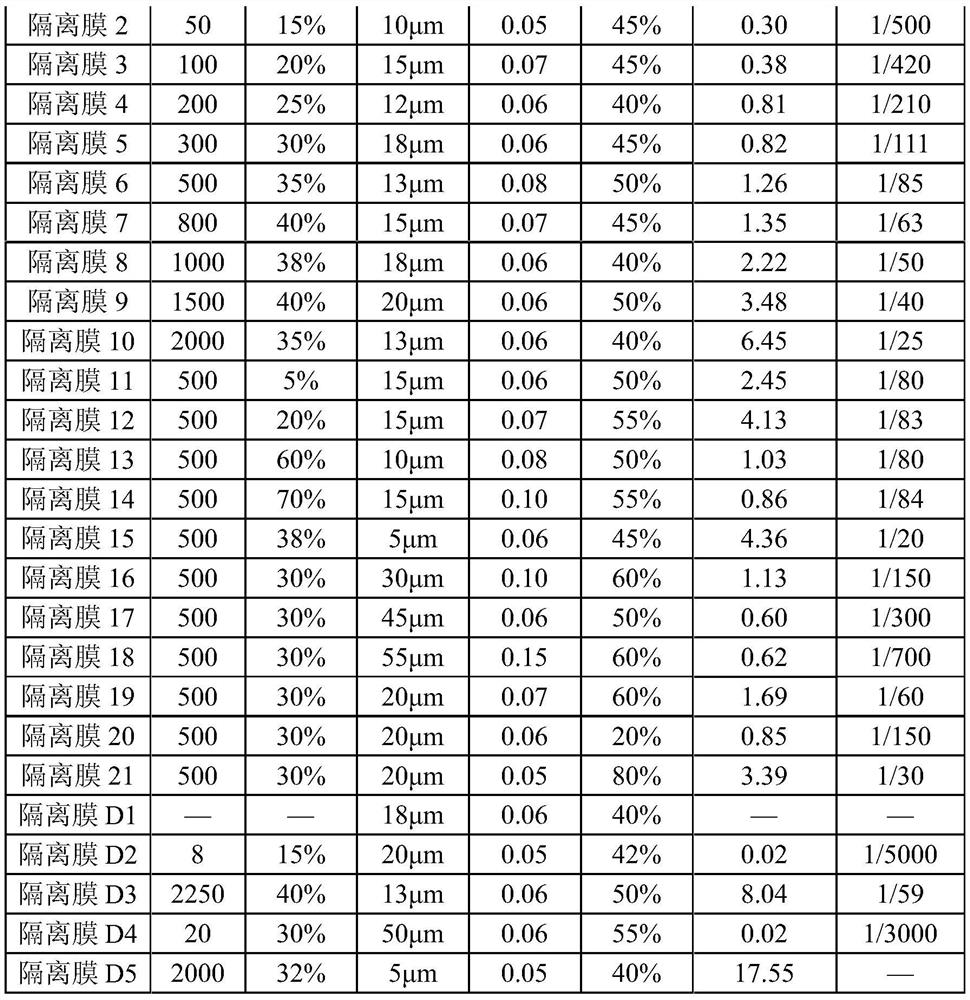

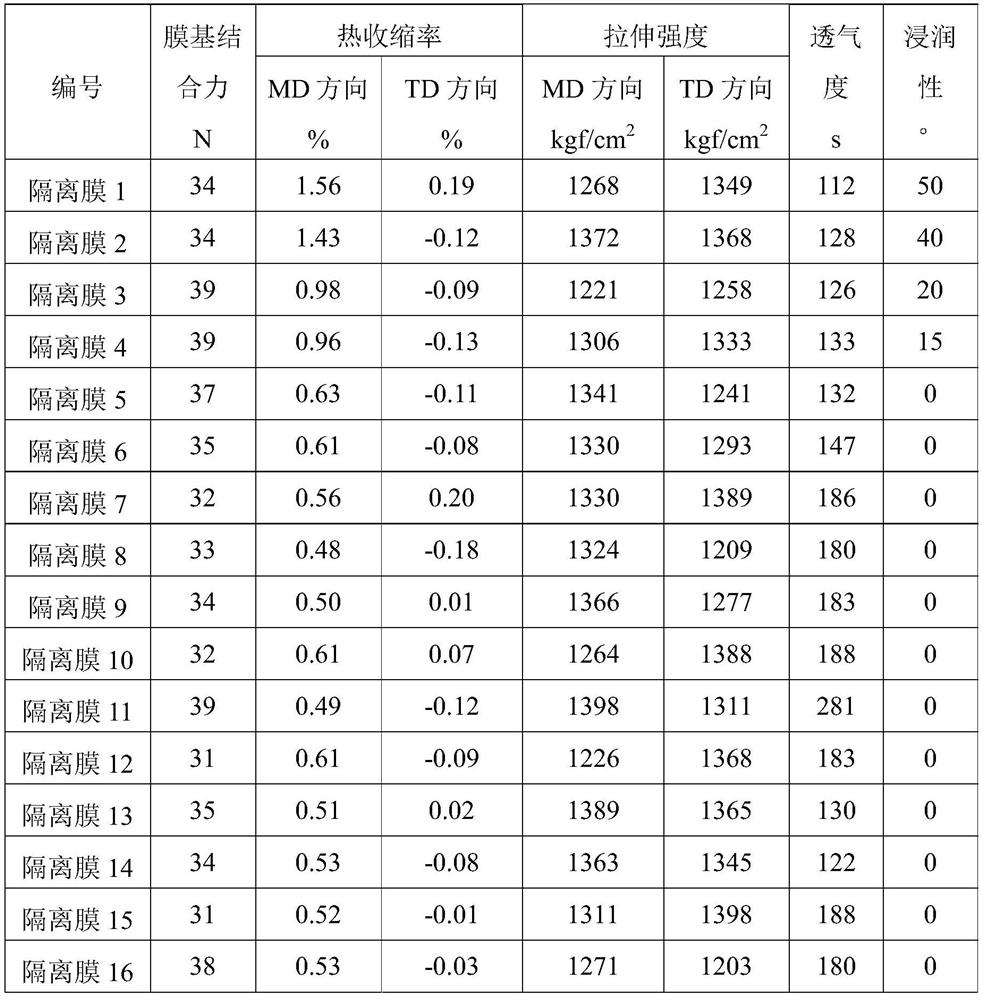

[0056] The specific parameters of the prepared separator are shown in Table 1.

[0057] Table 1

[0058]

[0059]

[0060] Among them, "—" indicates that the layer structure is not set.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com