Wood-plastic composite tray

A technology of wood-plastic composite materials and pallets, which is applied in the field of plastic product production, can solve problems such as environmental pollution, destruction of agricultural ecological balance, waste of resources, etc., and achieve the effects of excellent mechanical and mechanical properties, high ecological benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

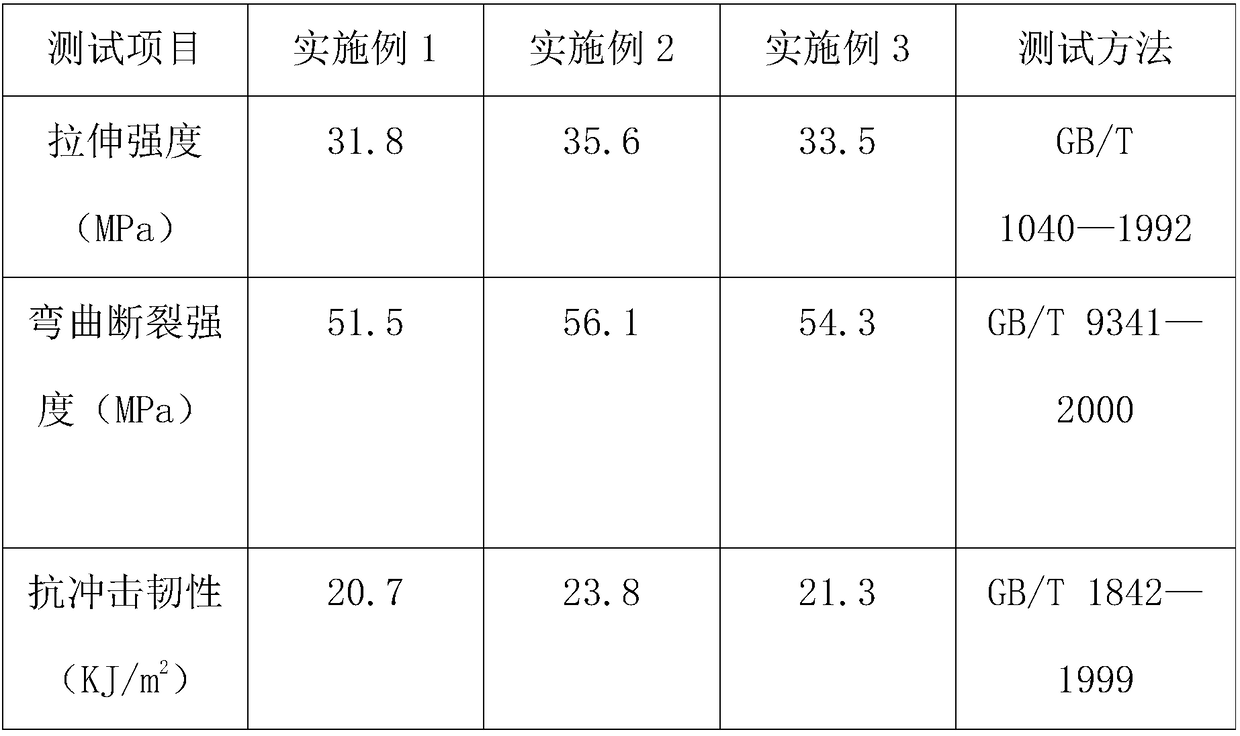

Examples

preparation example Construction

[0024] The preparation method of the modified wood flour is as follows: evenly spray the composite enzyme preparation on the wood flour, control the temperature to 45-55° C., and soak it in NaOH solution with a concentration of 5-10 wt% for 24-24 hours after enzymatic hydrolysis for 35-45 hours. After 36 hours, the wood powder was washed to neutrality, and then dried until the water content was lower than 3%, to obtain modified wood powder; the mass ratio of the composite enzyme preparation, wood powder, and NaOH solution was 0.5-1.5:100:400 -800.

[0025] The wood-plastic composite tray is prepared as follows: Weigh each raw material according to the preset value, then add the plastic base material, modified wood powder, coupling agent, antioxidant, and colorant into a high-speed mixer and mix Uniform, get the mixture; then send the mixture into the twin-screw extruder to granulate to get the pellets; then use the injection machine to inject the pellets into the molding mold,...

Embodiment 1

[0027] The present invention proposes a wood-plastic composite tray, the raw materials of which include by weight: 30 parts of PE recycled material, 70 parts of modified wood flour, 0.1 part of silane coupling agent KH550, 0.1 part of sodium stearate, antioxidant 10761.5 parts, 0.5 parts of 2,6-di-tert-butyl-4-methylphenol, 0.1 parts of black masterbatch.

[0028] The preparation method of the modified wood flour is as follows: evenly spray the compound enzyme preparation on the wood flour, control the temperature to 45° C., and after enzymatic hydrolysis for 45 hours, soak the wood flour with a concentration of 5wt% NaOH solution for 36 hours, and then wash the wood flour until Neutral, and then dried until the water content is lower than 3%, to obtain modified wood flour. The compound enzyme preparation is composed of pectinase and cellulase in a weight ratio of 1:6; the mass ratio of the compound enzyme preparation, wood powder, and NaOH solution is 1.5:100:400; the wood po...

Embodiment 2

[0031]The present invention proposes a wood-plastic composite pallet, the raw materials of which include by weight: 50 parts of PP regenerated material, 50 parts of modified wood powder, 1 part of silane coupling agent KH560, 1 part of titanate coupling agent NDZ102, 1 part of zinc stearate, 22460.1 parts of antioxidant, 1 part of black masterbatch.

[0032] The preparation method of the modified wood powder is as follows: evenly spray the compound enzyme preparation on the wood powder, control the temperature to 55°C, and after enzymatic hydrolysis for 35 hours, soak the wood powder with a concentration of 10wt% NaOH solution for 24 hours, and then wash the wood powder until Neutral, and then dried until the water content is lower than 3%, to obtain modified wood powder. The compound enzyme preparation is composed of pectinase and cellulase in a weight ratio of 1:8; the mass ratio of the compound enzyme preparation, wood powder, and NaOH solution is 0.5:100:800; the wood powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com