A kind of silica gel pad and its application in the preparation of lithium ion battery

A lithium-ion battery, silicone pad technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of uneven pressure, lithium precipitation, and indentation on the surface of the battery cell, and increase the deformation capacity. , to ensure fit, reduce the effect of the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] A1. Preparation of bare cell: Generally, a positive electrode sheet, a negative electrode sheet, and a diaphragm can be used to make a bare cell through lamination or winding processes, and the diaphragm is a rubber-coated diaphragm. The adhesive layer of the glue-coated diaphragm is made of a slurry system composed of an aqueous solvent and a binder polymer, or a slurry system composed of an oily solvent and a binder polymer; the binder polymer, Including one or more of polyvinylidene fluoride (PVDF), polyvinylidene fluoride-hexafluoropropylene, polyvinylidene fluoride-trifluoropropylene, acrylate and other derivatives; the oily solvent is acetone , tetrahydrofuran, N-methylpyrrolidone (NMP), dichloromethane, chloroform, or a mixture of any two or more. The slurry system of the adhesive layer is preferably a slurry system of an oily solvent and polyvinylidene fluoride or polyvinylidene fluoride-hexafluoropropylene solution; the adhesive layer contains ceramic particles...

Embodiment 2

[0063] The difference from Example 1 is:

[0064] A1. Preparation of bare cells: Assemble the single-tab positive electrode sheet, the single-tab negative electrode sheet, and the rubber-coated separator in a laminated manner to form a bare cell. The thickness of the bare cell is 4.2-4.7mm.

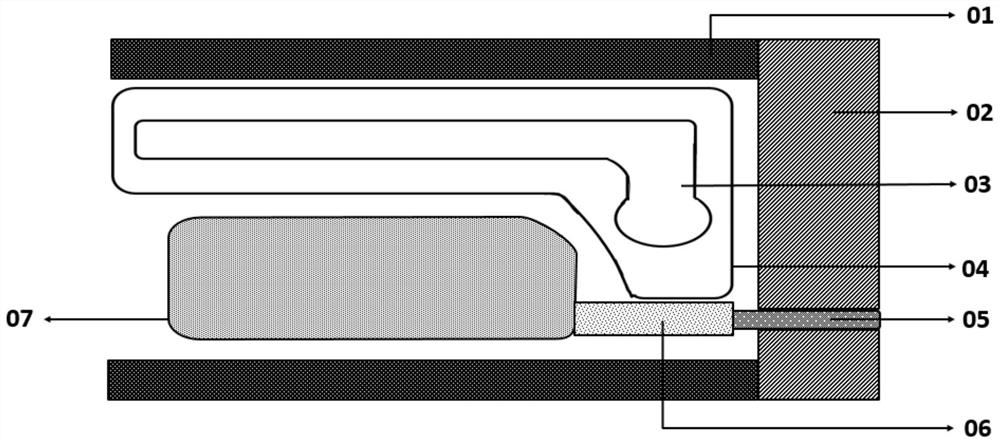

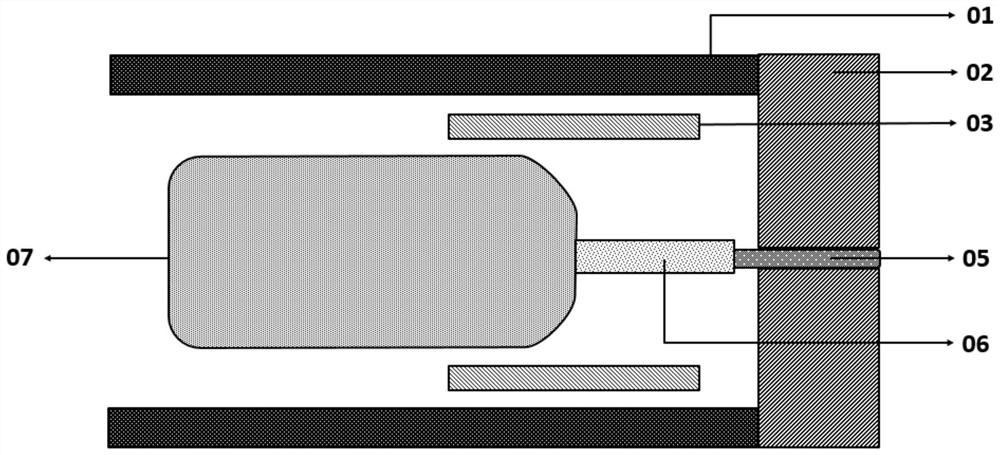

[0065] The preparation of the shell, the shell of this embodiment is a single inner pit shell;

[0066] A2. Put the bare cell into the inner pit, wrap the shell with the bare cell and fold it in half before packaging. After packaging, bake and infiltrate in turn to prepare the cell 07 to be formed.

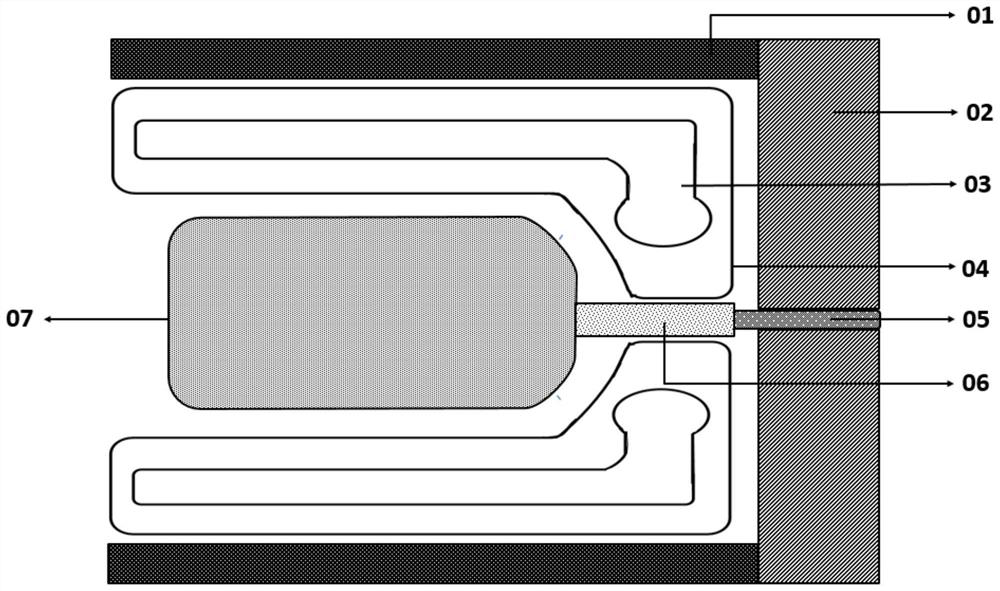

[0067] After completing the above steps, install the silicone pad 04 on the splint 01 of the fixture, and the L-shaped short side plate surface needs to be installed at the end where the tab 05 is placed. In this embodiment, since the shell is a single-pit shell, a silicone pad 04 is installed on the splint 01 of the fixture on the side of the pit. After the silicone pad 04 is installed, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com