Method for preparing porous carbon heat source material

A porous carbon and heat source technology, applied in the application, tobacco, smoker's products and other directions, can solve the problems of material flammability and mechanical strength damage, reduce processing tolerance and thermal collapse resistance, reduce material mechanical strength and other problems, To achieve smooth heat flow transfer, avoid the reduction of mechanical strength, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

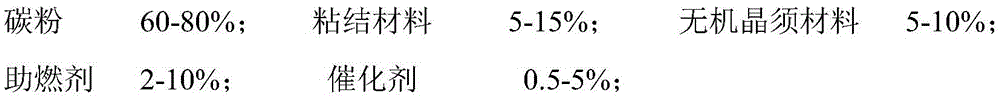

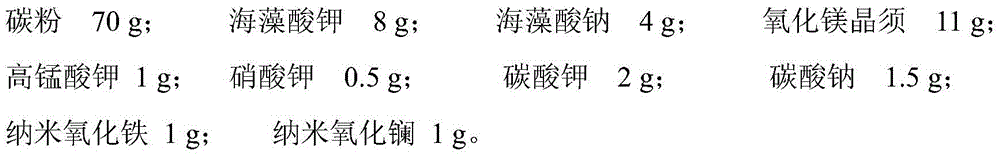

[0025] The composition of each component of the porous carbonaceous heat source material in this embodiment is as follows:

[0026]

[0027] The above-mentioned raw materials and 60g water are initially mixed, and then sent into the screw extruder to continue mixing, while blowing agent CO 2 It is poured into an extruder, extruded after foaming, and then dried and cut to obtain a porous carbonaceous heat source material.

[0028] The screw process parameters are set as follows: the temperature is 25-35° C., and the screw speed is 100 rpm.

[0029] Blowing agent CO 2 The injection flow rate is 6mL / min.

Embodiment 2

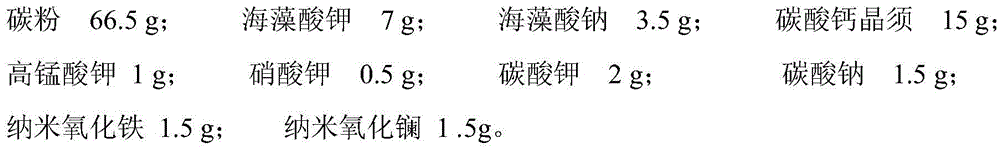

[0031] The composition of each component of the porous carbonaceous heat source material in this embodiment is as follows:

[0032]

[0033] The above-mentioned raw materials and 100g water are initially mixed, and then sent into the screw extruder to continue mixing, while blowing agent CO 2 It is poured into an extruder, extruded after foaming, and then dried and cut to obtain a porous carbonaceous heat source material.

[0034] The screw process parameters are set as follows: the temperature is 25-35° C., and the screw speed is 150 rpm.

[0035] Blowing agent CO 2 The injection flow rate is 10mL / min.

Embodiment 3

[0037] The composition of each component of the porous carbonaceous heat source material in this embodiment is as follows:

[0038]

[0039] The above-mentioned raw materials and 130g water are initially mixed, and then sent into the screw extruder to continue mixing, while blowing agent CO 2 It is poured into an extruder, extruded after foaming, and then dried and cut to obtain a porous carbonaceous heat source material.

[0040] The screw process parameters are set as follows: the temperature is 25-35° C., and the screw speed is 180 rpm.

[0041] Blowing agent CO 2 The injection flow rate is 16mL / min.

[0042] The carbonaceous heat sources prepared in Example 1, Example 2, and Example 3 were evaluated for three indicators: ignitability, CO release, and combustion shrinkage rate. The results are shown in Table 1.

[0043] It can be seen from Table 1 that the ignition temperature, CO emission and shrinkage rate of the carbonaceous heat source prepared by the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com