Noise-free waste-heat-regeneration commercial oil gas stove

A noiseless, oil-gas stove technology, applied in the field of oil-gas stoves, can solve the problems of energy waste and high combustion noise of ordinary stoves, and achieve the effects of low manufacturing cost, long life and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

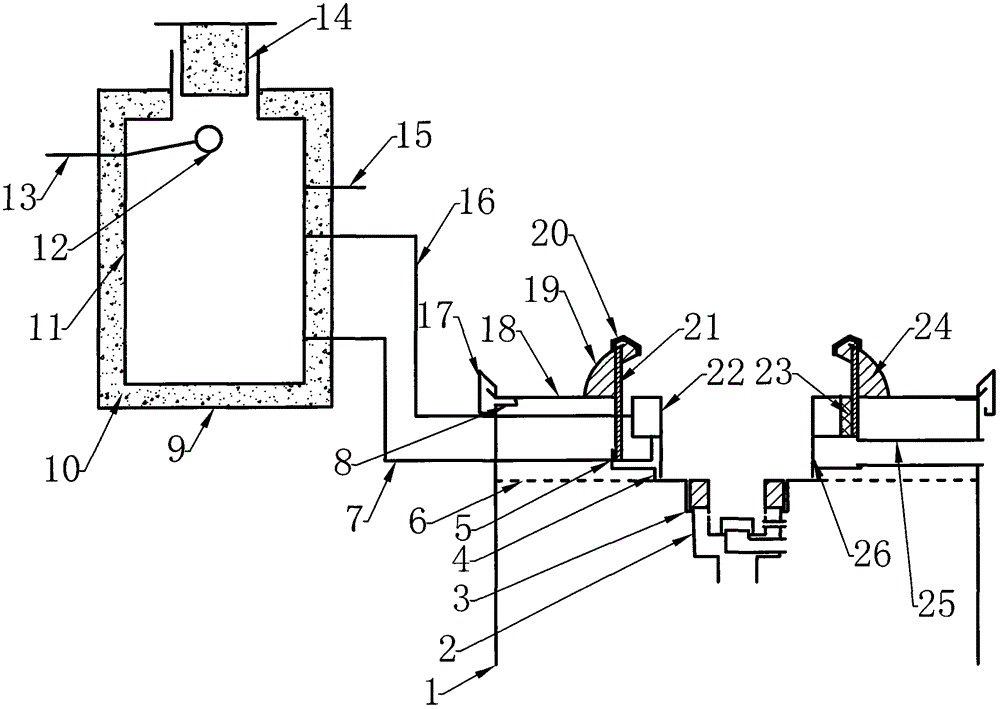

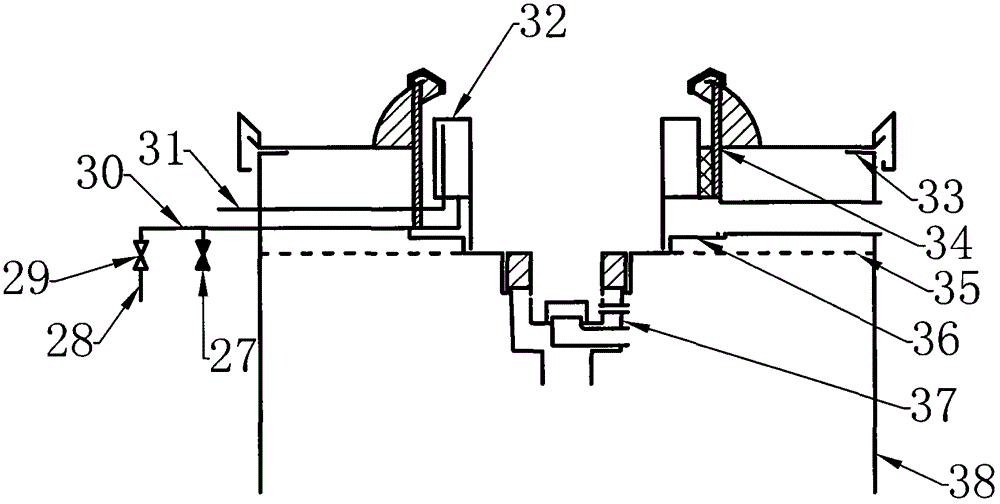

[0023] figure 1 A structural form of a noiseless waste heat regeneration commercial oil-gas stove is described. A noiseless waste heat regeneration commercial oil-gas stove mainly consists of a bracket, a waste heat recovery device, a base, a refractory ring, a combustion head, and an insulated water tank. The legs 1, the lower frame 6, and the upper frame 8 together form the bracket; the fixed step 5 of the refractory ring, the fixed step 4 of the first waste heat recovery device, and the fixed step 3 of the combustion head are connected to each other to form the first base, and the first base is integrated casting Forming or tailor welding, the first base is fixed on the lower frame 6; the main body 22 of the first waste heat recovery device is a hollow metal body whose shape is cylindrical, or truncated, prismatic, or truncated; the first waste heat The recoverer main body 22 has a ring-shaped wing 26 downward; the ring-shaped wing 26 is a tubular metal body with a cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com