Supercritical water treatment wet garbage poly-generation comprehensive utilization system and treatment process

A technology of supercritical water and treatment process, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, polluted groundwater/leachate treatment, etc. Solve the problems of oil quality and yield, semi-coke comprehensive utilization and other issues that have not been reported, and achieve the effect of high comprehensive utilization, high efficiency utilization and high oil production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

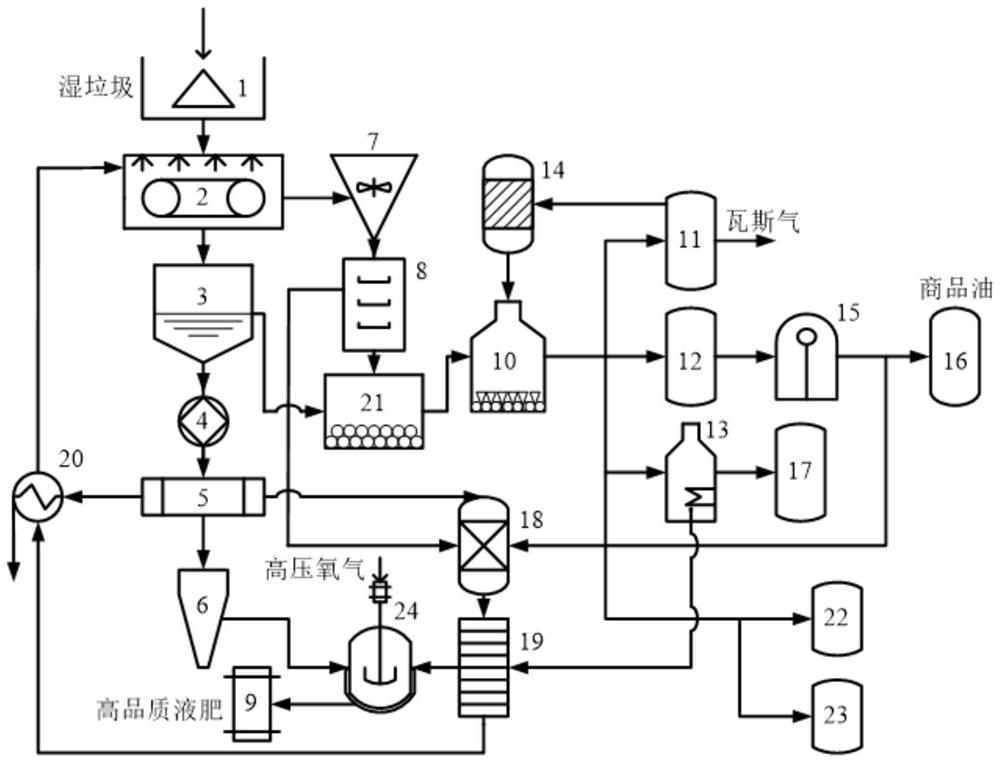

[0043] A supercritical water treatment wet garbage polygeneration comprehensive utilization system, such as figure 1 , the system includes: a liquid fertilizer output unit, used to convert the liquid in the wet garbage into high-quality liquid fertilizer, including a wet garbage wet liquid supply branch and a supercritical water supply branch; a commercial oil production unit, used to convert the wet The solid in the garbage is converted into commercial oil, including the oil phase supply branch and the solid phase supply branch;

[0044] The wet waste liquid supply branch and the supercritical water supply branch overlap the high-temperature steam shower device 2 and the oxidation reactor 24; the liquid fertilizer output unit also includes a leachate collector 6; the oil phase supply branch and the solid phase supply The branches overlap the high-temperature steam shower device 2 and the solid collector 21; the commercial oil production unit also includes a wet garbage solid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com