Commercial cooking fume treatment device of Internet of Things based on X86 master control

A technology for oil fume treatment and Internet of Things, which is applied in gas treatment, transportation and packaging, cleaning hollow objects, etc. It can solve the problems that affect the purification function, cannot accurately judge the cleaning time of filter elements and filter screens, and troublesome disassembly and viewing, etc. The effect of normal purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

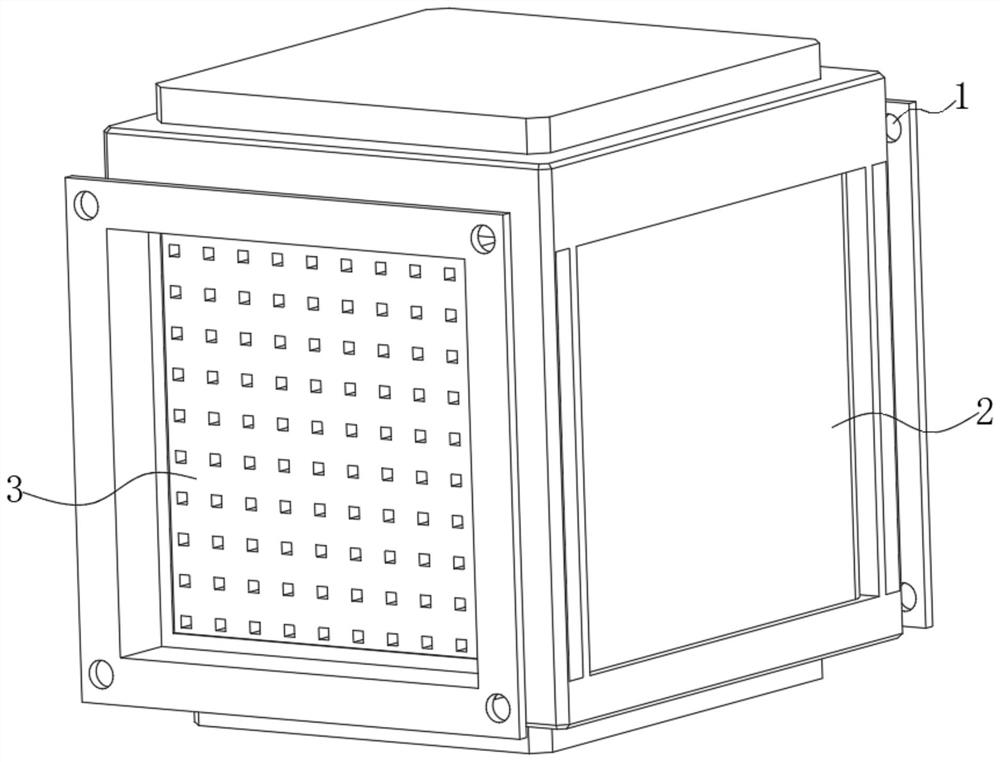

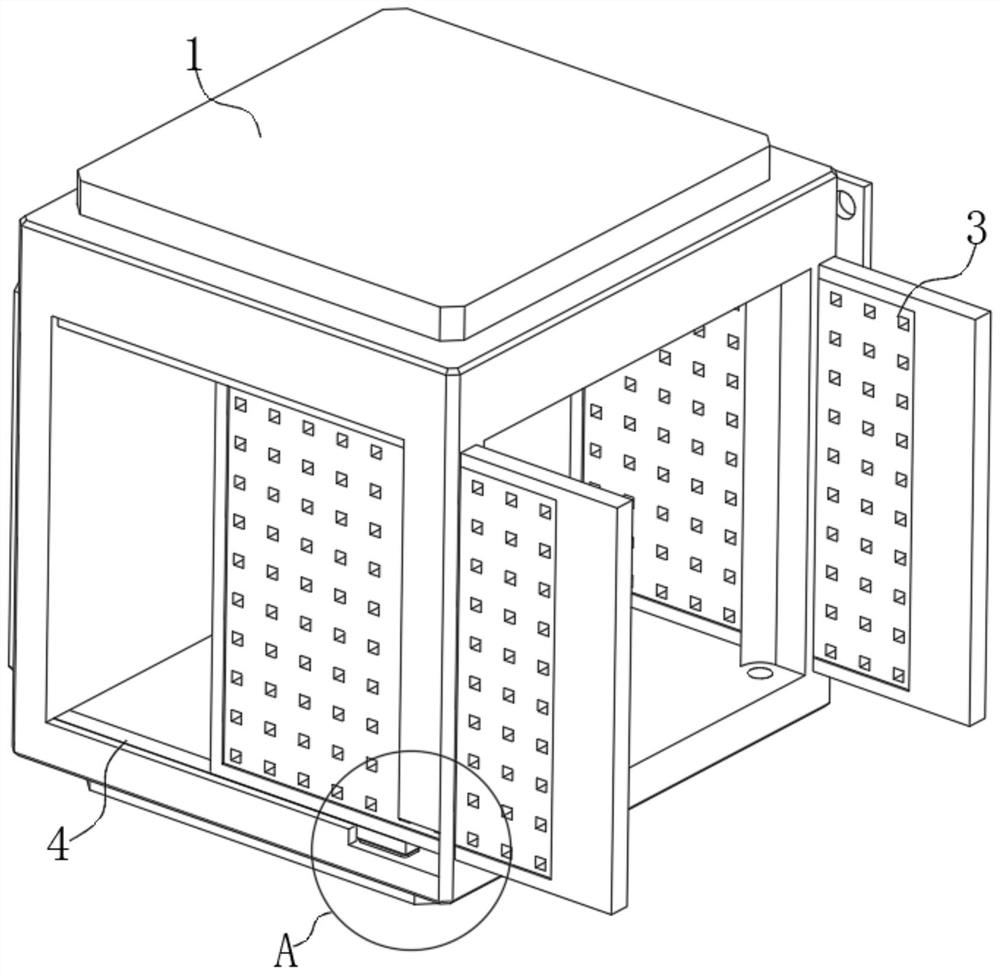

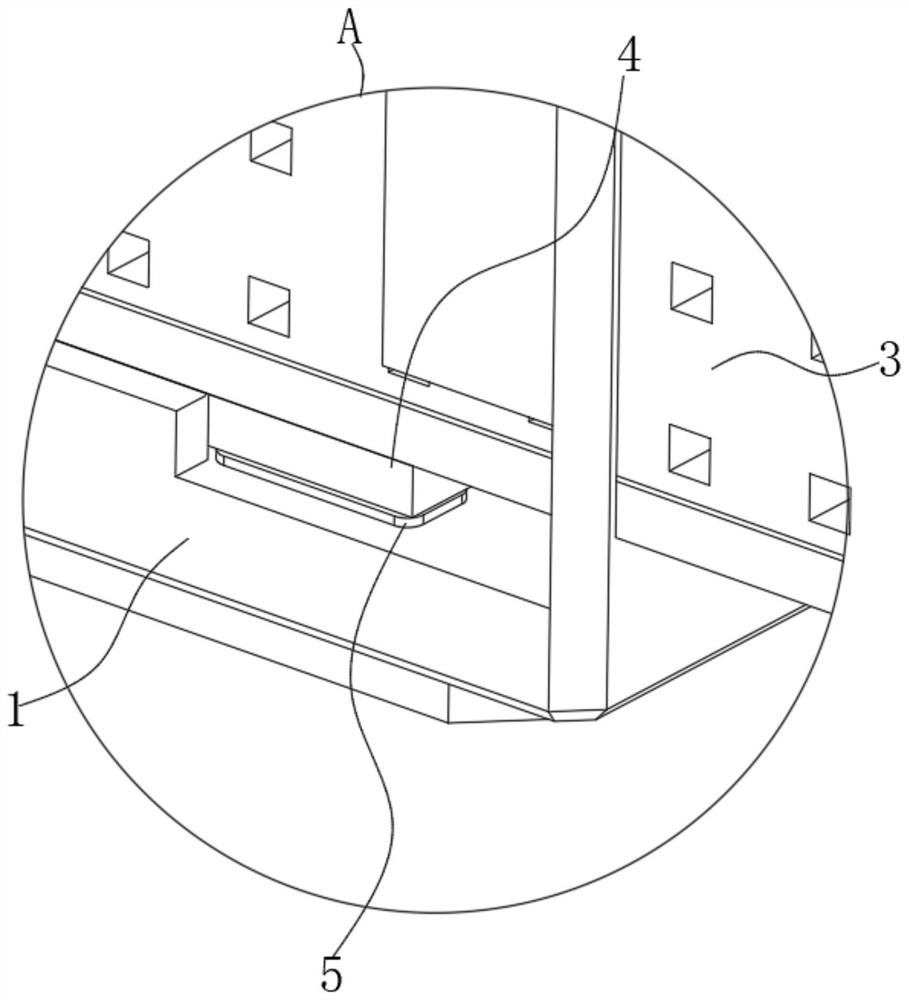

[0033] see Figure 1-Figure 3 Illustrate Embodiment 1. In the figure, an Internet of Things commercial lampblack processing device based on X86 master control includes a lampblack purifier body 1, a rotating assembly 6 and a push assembly 7. One side of the lampblack purifier body 1 is provided with an opening and closing door 2 , and the other two sides perpendicular to the switch door 2 are provided with a filter screen 3 located inside the oil fume purifier body 1, and the filter screen 3 is slidably connected with the oil fume purifier body 1, and the bottom end of the filter screen 3 is installed with the oil fume purification device. The installation bar 4 is fixedly connected to the main body 1 of the oil fume purifier. The bottom end of the installation bar 4 is fixedly connected with a pressure sensor 5. The rotating assembly 6 for turning the switch door 2 is installed in the oil fume purifier main body 1, and is used to push the filter screen 3. The assembly 7 is in...

Embodiment 2

[0046] see Figure 9 and Figure 11 The second embodiment will be described. This embodiment will further describe the first embodiment. In the figure, the rotation limiting member 23 includes a rotating disk 35 that is fixedly connected to the drive shaft 15. One end of the rotating disk 35 is rotatably connected with a ratchet gear 36. The ratchet gear 36 A ratchet 37 is engaged with the outer side of the ratchet, the outer surface of the ratchet 37 is fixedly connected with a second spring 38, and one end of the second spring 38 is fixedly connected with a fixed block 39 that is fixedly connected to the rotating disk 35;

[0047] In the present embodiment, when the motor 13 drives the drive shaft 15 to rotate forward, the rotating disk 35 rotates forward, which in turn drives the pawl 37 to rotate forward. Therefore, at this time, the pawl 37 can drive the ratchet gear 36 to rotate, thus driving the first reciprocating When the screw rod 24 rotates, when the drive shaft 15...

Embodiment 3

[0049] see Figure 12 and Figure 13 Example 3 is described. This embodiment further describes Example 1. In the figure, the cleaning member 30 includes a rotating shaft 40 that is fixedly connected to the first reciprocating screw rod 24. One end of the rotating shaft 40 is fixedly connected to the lampblack purifier body. 1. A rotatably connected worm 41, the outer surface of the worm 41 is engaged with a turbine 42, and both ends of the turbine 42 are fixedly connected with a second reciprocating screw 43 that is rotatably connected to the oil fume purifier body 1, and the second reciprocating screw 43 is threaded A second threaded block 44 is connected, a connecting block 45 is fixedly connected to the bottom end of the second threaded block 44, and a cleaning frame 46 is slidably connected to the connecting block 45. 3 inside;

[0050] In this embodiment, when the first reciprocating screw 24 rotates, it will drive the rotating shaft 40 to rotate, thus driving the worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com