Super-hydrophilic and super-oleophobic oil-water separation ceramic membrane as well as preparation method and application thereof

An oil-water separation, ceramic membrane technology, applied in separation methods, immiscible liquid separation, liquid separation and other directions, can solve the problem of not very high circulation, achieve the effect of simple preparation process, short cycle and solving complex preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Add 10wt% pore-forming agent PVA to the alumina powder, hold it under a pressure of 8MPa for 3 minutes, dry press molding, the thickness is 2mm, and then cold isostatic pressing under a pressure of 200MPa for 200s to obtain a molded ceramic blank body;

[0031] 2. Sinter the shaped ceramic body at 1550°C for 1 hour, then immerse it in a liquid mixture consisting of TEOS / PDMS with a mass ratio of 1:1, and then transfer it to a reaction chamber filled with 15wt% HCl vapor, And equilibrate at a temperature of 60° C. for 60 minutes; dry in an oven at 40 to 60° C. for 2 to 4 hours to remove the generated water and obtain a ceramic membrane for oil-water separation.

[0032] The oil-water separation efficiency of the obtained oil-water separation ceramic membrane is as high as 98%, and the separation efficiency is still as high as 97% after being recycled for 10 times.

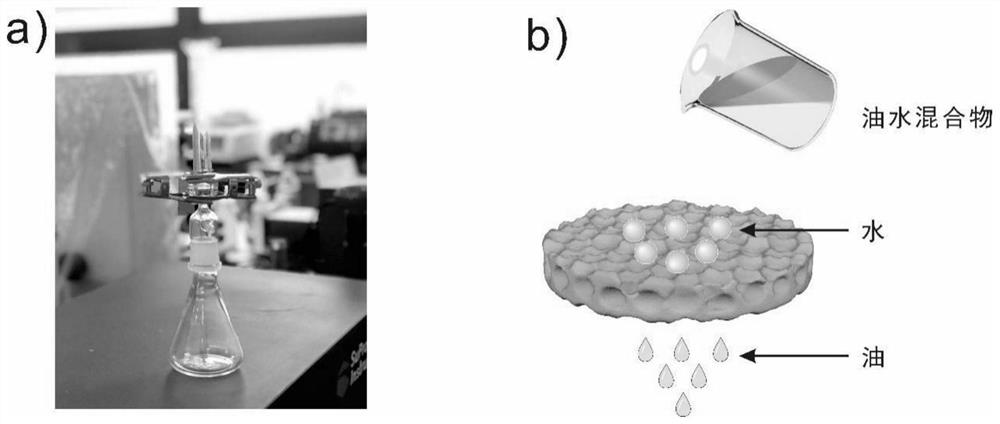

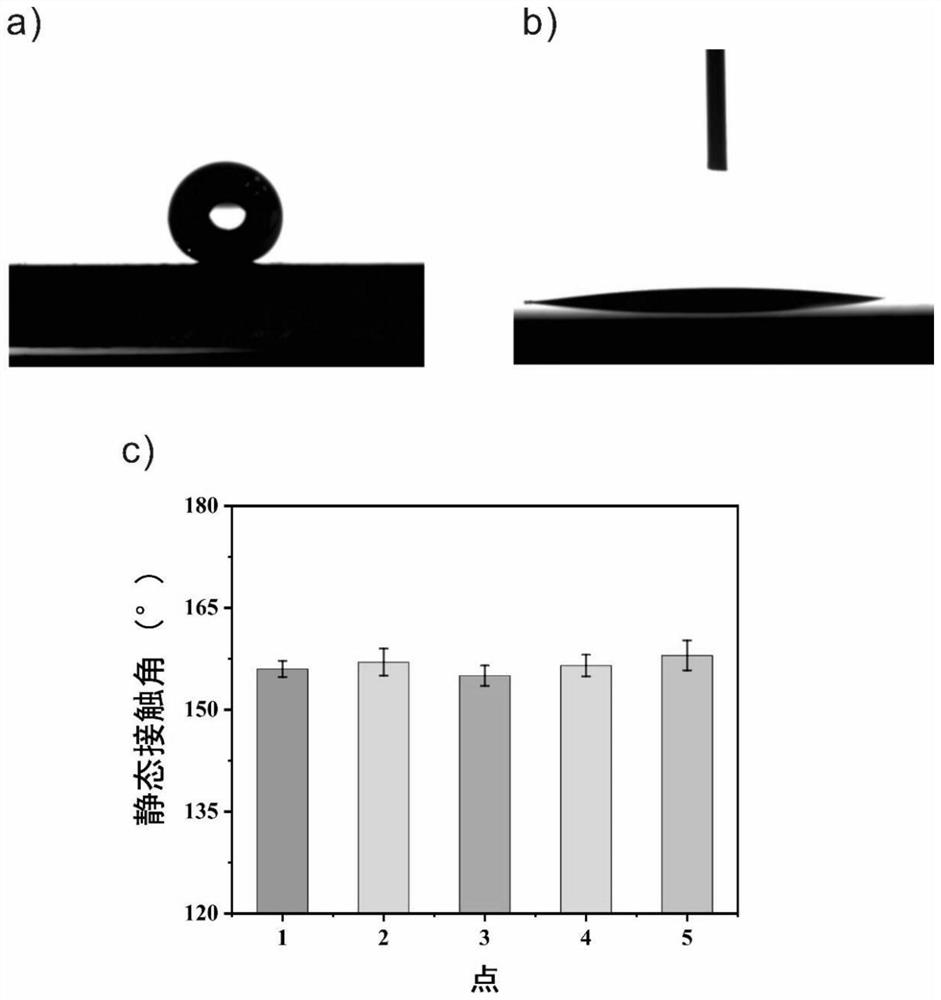

[0033] figure 1 Among them, (a) is the oil-water separation device used in the present invention; (b)...

Embodiment 2

[0036] 1. Add 10wt% PVA to the zirconia powder, keep it under 8MPa pressure for 3 minutes to dry press molding, the thickness is 2mm, and then cold isostatic pressing under 200MPa pressure for 200s to make a molded ceramic body;

[0037] 2. Sinter the formed ceramic green body at 1550 °C for 1 h, then immerse it in a mixed liquid of TEOS and PDMS with a mass ratio of 1:1, and then transfer it to a reaction chamber filled with 15 wt% HCl vapor, and heat it at 60 Equilibrate at ℃ for 60 minutes, and dry in an oven at 40℃ for 4 hours to prepare a ceramic membrane for oil-water separation.

[0038] The oil-water separation efficiency of the obtained oil-water separation ceramic membrane is as high as 95%, and the separation efficiency is still as high as 93%.

Embodiment 3

[0040] 1. Add 20wt% PVA to the alumina powder, keep dry pressing for 3 minutes under the pressure of 8MPa, the thickness is 2mm, and then cold isostatic pressing under the pressure of 200MPa for 200s to obtain the molded ceramic body;

[0041] 2. Sinter the formed ceramic body at 1550 ° C for 1 h, then immerse it in a mixed liquid composed of TEOS and PDMS with a mass ratio of 1:1, and then transfer the block to a reaction chamber filled with 15 wt% HCl vapor, and Equilibrate at 60°C for 60min, and dry in an oven at 60°C for 2h to remove the generated water to prepare a ceramic membrane for oil-water separation.

[0042] The oil-water separation efficiency of the obtained oil-water separation ceramic membrane is as high as 97%, and after 10 cycles, the separation efficiency is still as high as 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com