Oil lubrication compressor gas supplied circulating refrigerating device

A refrigeration device and oil lubrication technology, which is applied in the field of circulating refrigeration devices and circulating refrigeration devices supplied by oil-lubricated compressors, can solve problems such as cost increase, temperature reduction, and service life reduction, and achieve efficiency improvement, simple processing, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

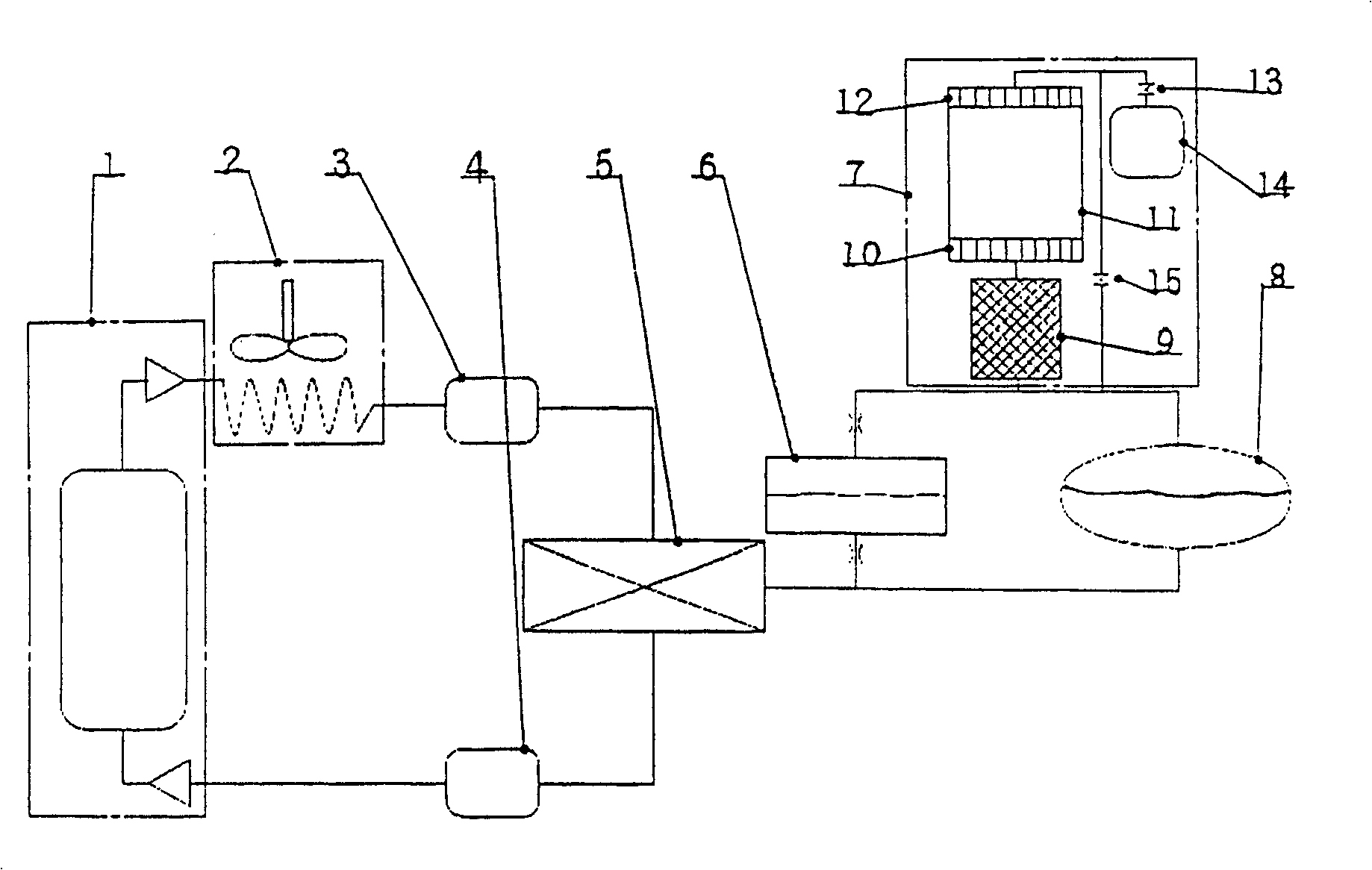

[0045] Embodiment 1 A circulating refrigeration device for air supply of an oil-lubricated compressor of the present invention (the refrigerator is a single-supply air-supply bidirectional intake pulse tube refrigerator):

[0046] The circulating refrigeration device (two-way air intake) of the oil-lubricated compressor air supply of the present embodiment, such as figure 1 As shown, it includes: the high-pressure end of the oil-lubricated compressor 1 is connected to the condenser 2, and the high-pressure air storage tank 3 is connected to the rear, the low-pressure end of the oil-lubricated compressor 1 is connected to the low-pressure air storage tank 4, and the high-low pressure air storage tank 3 is connected to the The oil-lubricated rotary valve 5 communicates, and a box-type elastic membrane device 8 and a box-type balance gas storehouse 6 are installed in parallel between the oil-lubricated rotary valve 5 and the refrigerator 7; the refrigerator 7 is a two-way intake ...

Embodiment 2

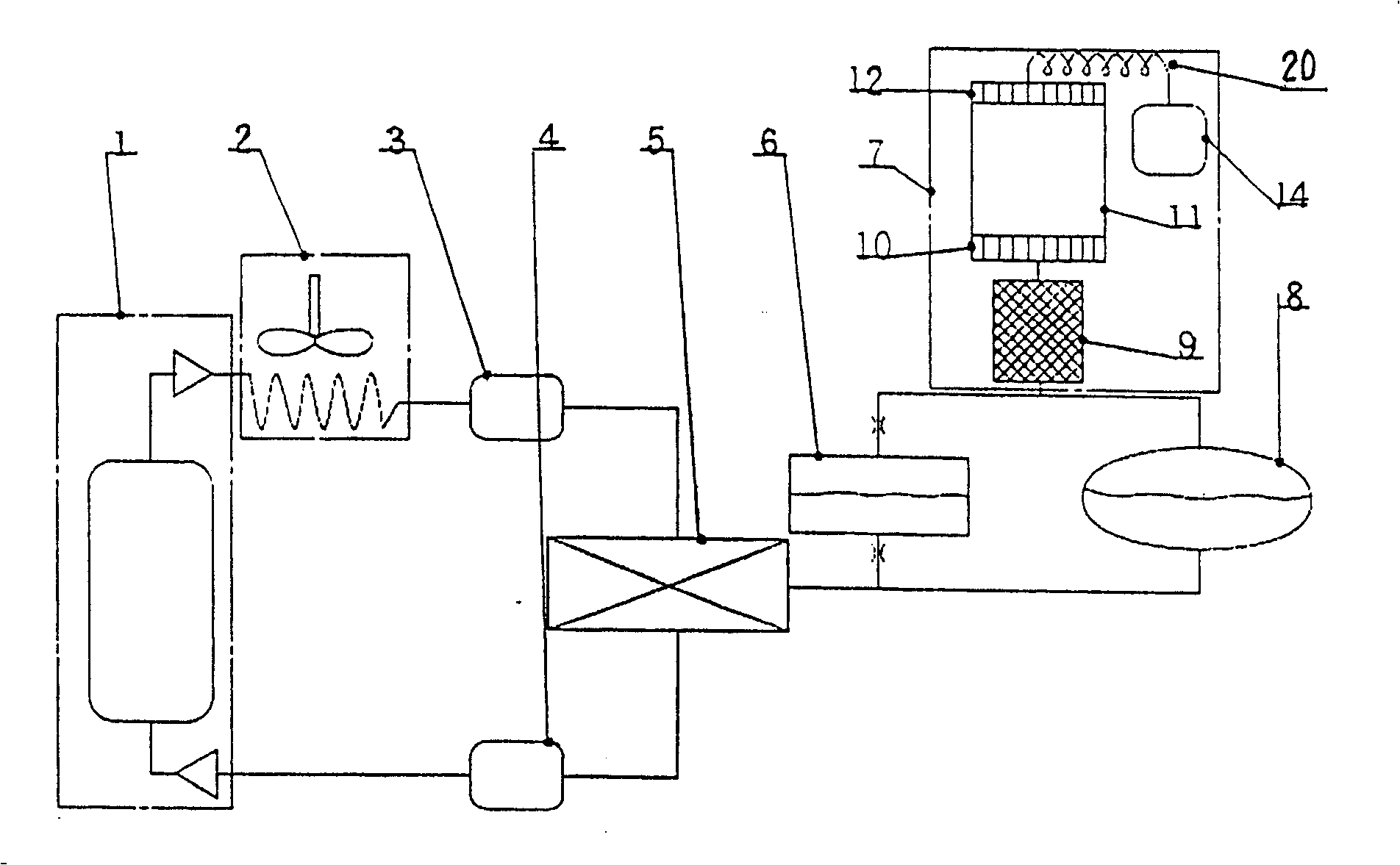

[0048] Embodiment 2 A circulating refrigeration device for oil-lubricated compressor air supply of the present invention (the refrigerator is a single-supply inertial tube phase-modulating type pulse tube refrigerator), except that the refrigeration part is an inertial tube phase-modulating type pulse tube refrigerator , the other parts are the same as figure 1 unanimous.

[0049] Such as figure 2 As shown, the circulating refrigeration device of the oil-lubricated compressor air supply of the present embodiment includes (1) a stable pressure wave generation system: the oil-lubricated (valve type) compressor 1 driven by a rotating motor to drive the crank connecting rod piston will use the working gas Compressed, the gas output from the high-pressure end is cooled by the condenser 2, and then enters the high-pressure gas storage tank 3, and its low-pressure end is connected with the low-pressure gas storage tank 4, and the high-pressure gas storage tank 3 and the low-pressu...

Embodiment 3

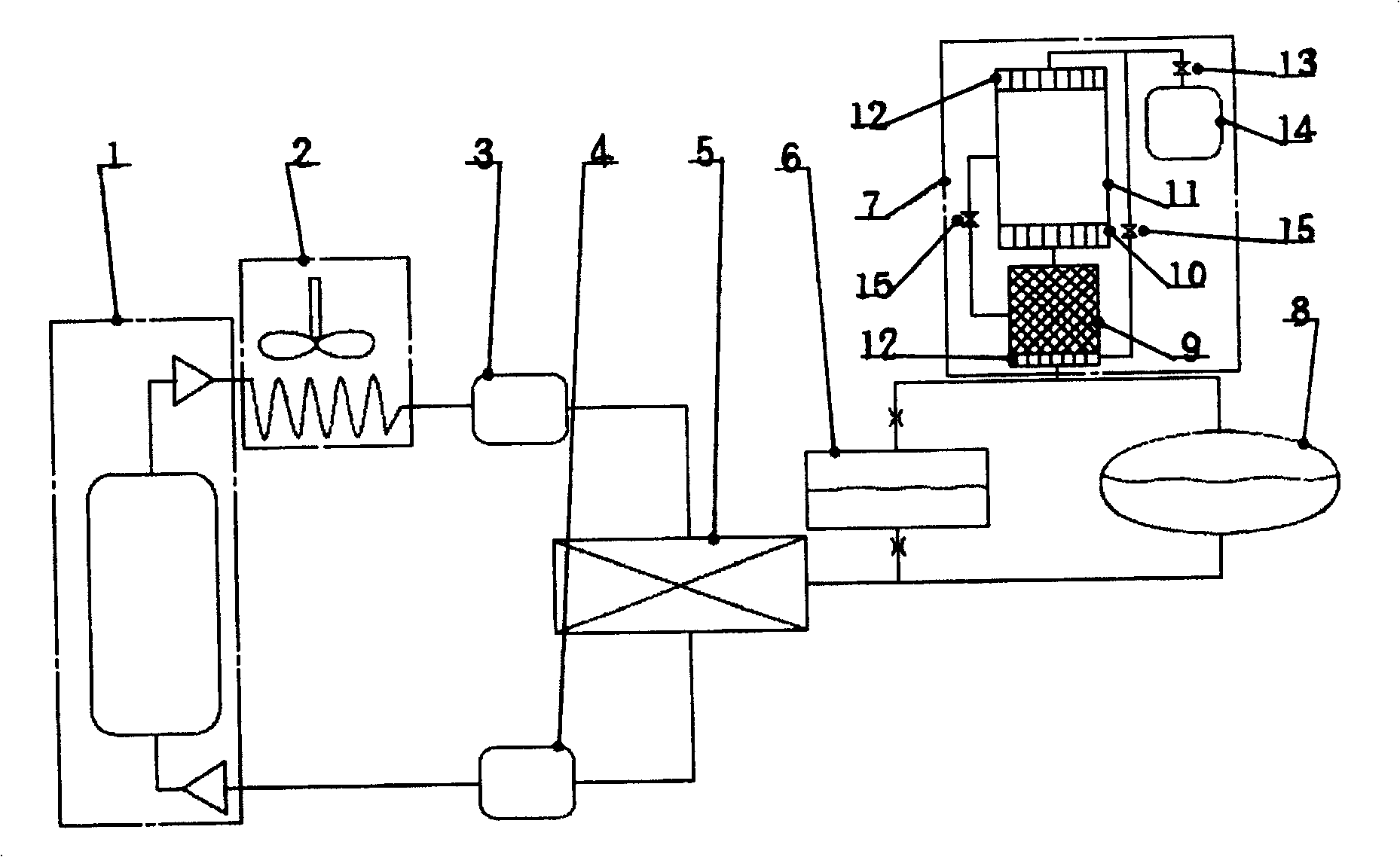

[0050] Embodiment 3 An oil-lubricated compressor air supply cycle refrigeration device of the present invention (the refrigerator is a single-supply multi-channel bypass pulse tube refrigerator), except that the refrigeration part is a multi-channel bypass pulse tube refrigerator, other parts are the same as figure 1 unanimous.

[0051] Such as image 3 As shown, the circulating refrigeration device for oil-lubricated compressor air supply in this embodiment includes (1) a stable pressure wave generation system: the screw compressor 1 compresses the working gas, and the gas output from the high-pressure end passes through the condenser 2 It is cooled, and then enters the high-pressure gas storage tank 3, and its low-pressure end is connected with the low-pressure gas storage tank 4, and the high-pressure gas storage tank 3 and the low-pressure gas storage tank 4 communicate with the two inlets of the oil-lubricated rotary valve 5 respectively, forming a stable (2) Oil-lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com