Pedal motorcycle special-purpose long-life low-noise lubricating oil

A lubricating oil and motorcycle technology, applied in the field of lubricating oil, can solve the problems of poor anti-wear durability and attenuation of anti-wear properties, and achieve the effects of good anti-friction durability, low friction performance, and excellent low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

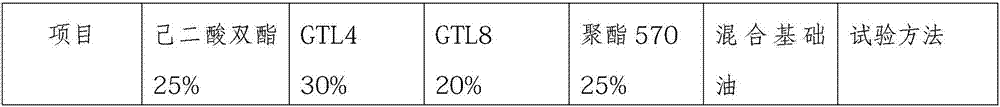

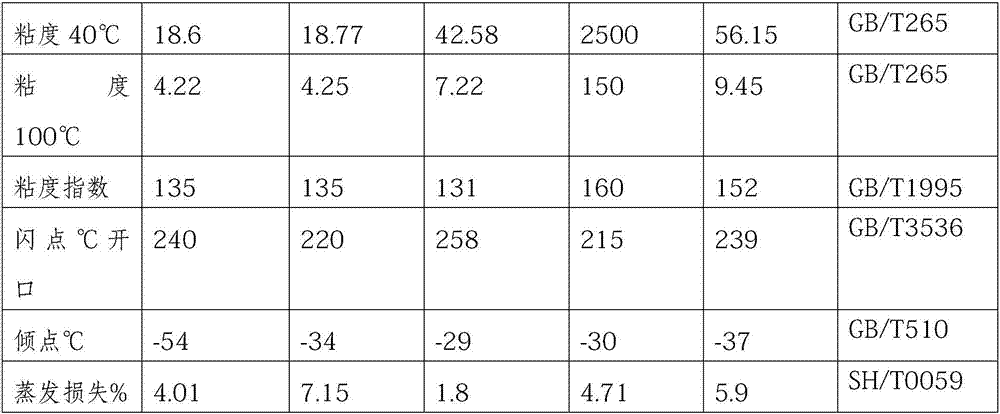

[0064] (1) Pump the various base oils in the proportions listed in Table 1 into the mixing tank with a gear pump, stir and heat to 40°C, and fully mix them with a static mixer for 1.5 hours to obtain a uniformly mixed base oil ;

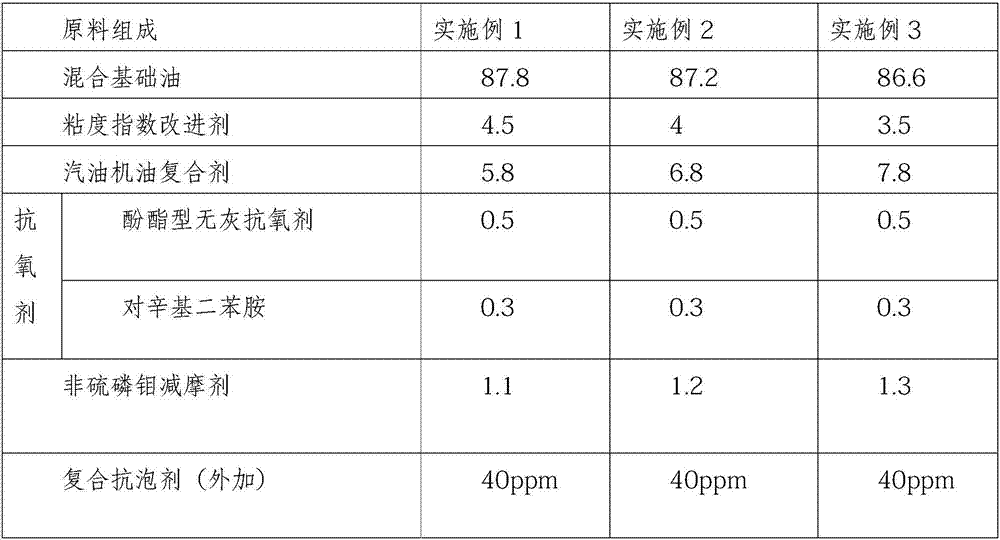

[0065] (2) Pump 1 / 2 of the 87.8wt% mixed base oil into the blending kettle with a gear pump, add 4.5wt% viscosity index improver, stir and heat to 80-85°C, and carry out by stirring and static mixer Fully mixed, time 0.5h

[0066] (3) Add 0.5wt% phenolic ester type antioxidant and 0.3wt% dioctyldiphenylamine antioxidant, fully mix by stirring and static mixer, time 0.5h;

[0067] The above process is carried out under the protection of 0.1MPa nitrogen, let off the nitrogen, and degas at -0.06MPa for 0.5h;

[0068] (4) Add the remaining 1 / 2 mixed base oil, lower the temperature to 50-55°C, release the negative pressure, add 5.8wt% gasoline engine oil compounding agent, 1.1wt% non-sulfur phosphorus molybdenum friction reducer, and add 40ppm Composit...

Embodiment 2

[0070] (1) Pump the various base oils in the proportions listed in Table 1 into the mixing tank with a gear pump, stir and heat to 40°C, and fully mix them with a static mixer for 1.5 hours to obtain a uniformly mixed base oil ;

[0071] (2) Pump 1 / 2 of 87.2wt% of the mixed base oil into the blending kettle with a gear pump, add 4wt% of viscosity index improver, stir and heat to 80-85°C, fully carry out by stirring and static mixer Mixing time 0.5h

[0072] (3) Add 0.5wt% phenolic ester type antioxidant and 0.3wt% dioctyldiphenylamine antioxidant, fully mix by stirring and static mixer, time 0.5h;

[0073] The above process is carried out under the protection of 0.1MPa nitrogen, let off the nitrogen, and degas at -0.06MPa for 0.5h;

[0074] (4) Add the remaining 1 / 2 mixed base oil, lower the temperature to 50-55°C, release the negative pressure, add 6.8wt% gasoline engine oil compounding agent, 1.2wt% non-sulfur phosphorus molybdenum friction reducer, and add 40ppm Composit...

Embodiment 3

[0076] (1) Pump the various base oils in the proportions listed in Table 1 into the mixing tank with a gear pump, stir and heat to 40°C, and fully mix them with a static mixer for 1.5 hours to obtain a uniformly mixed base oil ;

[0077] (2) Pump 1 / 2 of the 86.6wt% mixed base oil into the blending kettle with a gear pump, add 3.5wt% viscosity index improver, stir and heat to 80-85°C, and carry out by stirring and static mixer Fully mixed, time 0.5h

[0078] (3) Add 0.5wt% phenolic ester type antioxidant and 0.3wt% dioctyldiphenylamine antioxidant, fully mix by stirring and static mixer, time 0.5h;

[0079] The above process is carried out under the protection of 0.1MPa nitrogen, let off the nitrogen, and degas at -0.06MPa for 0.5h;

[0080](4) Add the remaining 1 / 2 mixed base oil, lower the temperature to 50-55°C, release the negative pressure, add 7.8wt% gasoline engine oil compounding agent, 1.3wt% non-sulfur phosphorus molybdenum friction reducer, and add 40ppm Composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com