Emulsion ferrous metal (steel) antirust solution

A metal anti-rust, emulsion-type technology, applied in the direction of anti-corrosion coatings, etc., can solve the problem of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

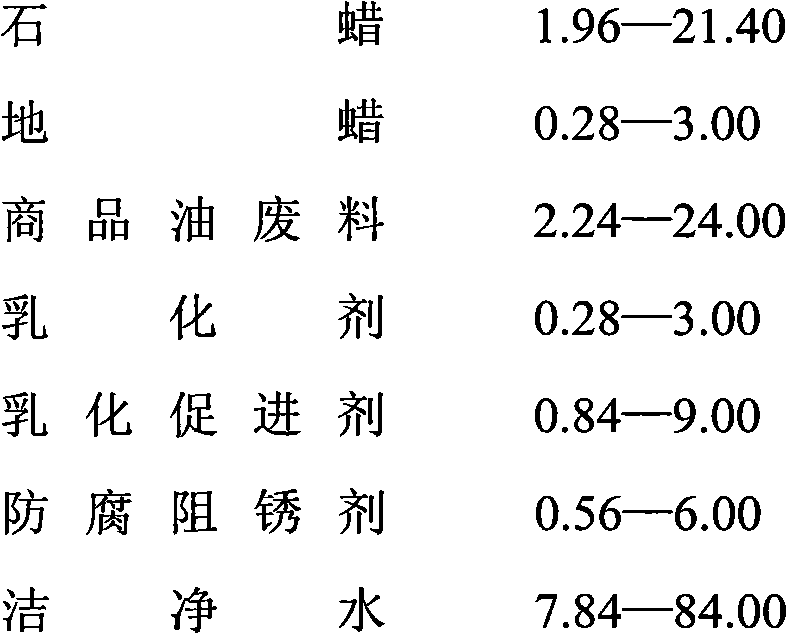

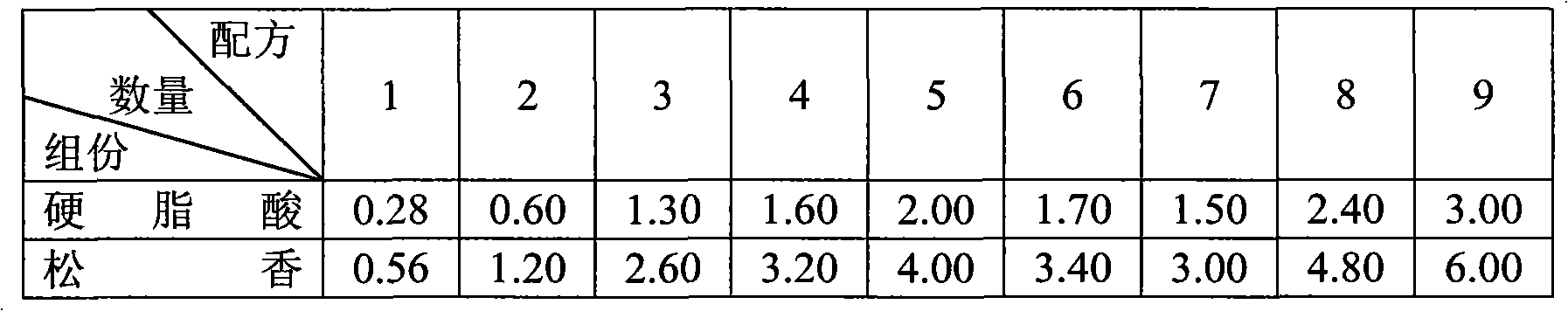

Method used

Image

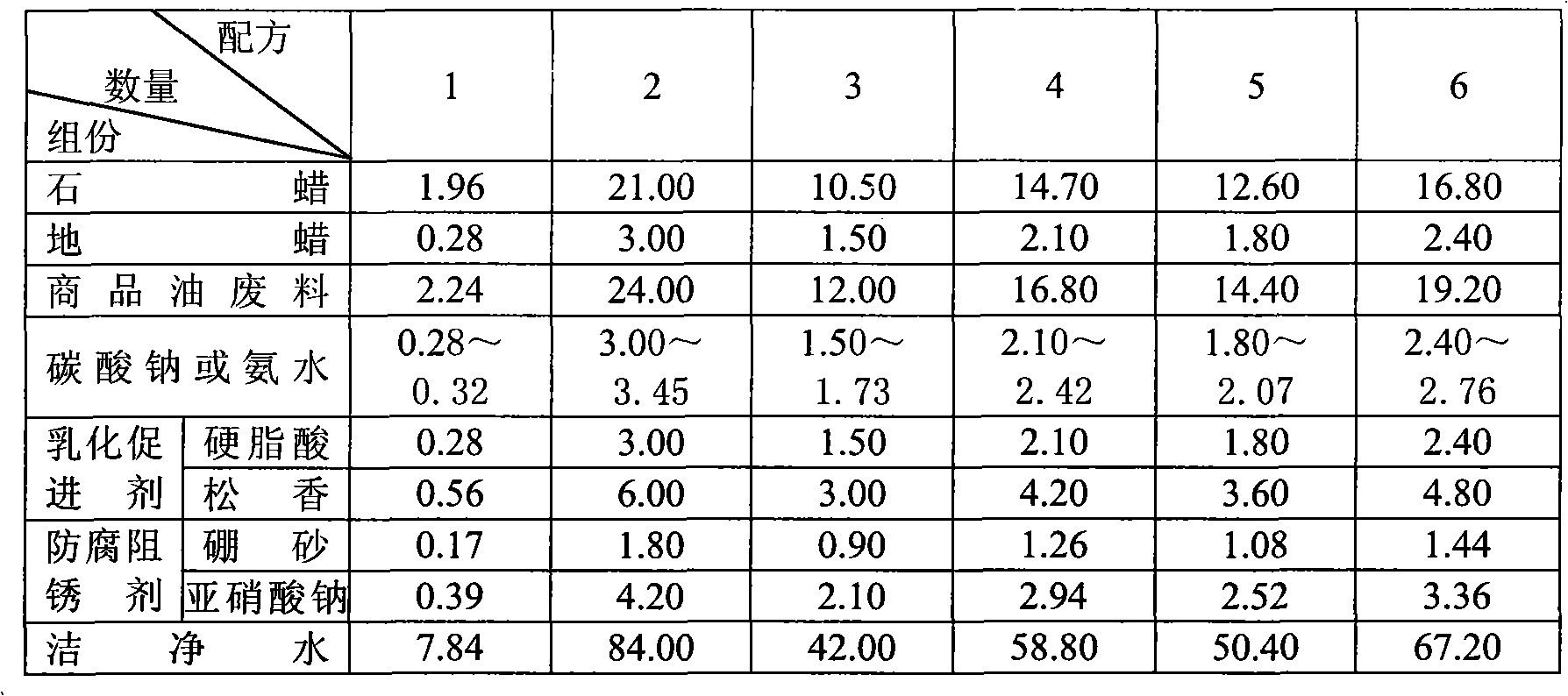

Examples

Embodiment 1

[0030] Example 1: paraffin wax 21.00, ozokerite 3.00, oil 24.00, sodium carbonate 3.00, stearic acid 3.00, rosin 6.00, borax 1.80, sodium nitrite 4.20, clean water 84.00.

[0031] When preparing, add borax and sodium nitrite to water, heat to about 40°C to make anti-corrosion and anti-rust liquid; add the rest of the raw materials into the emulsification pot, heat and melt; under strong stirring, slowly add anti-corrosion and anti-rust liquid and mix well ; After the emulsion becomes thinner from thick, the product of the present invention can be obtained.

Embodiment 2

[0032] Embodiment 2: paraffin wax 12.60, ozokerite 1.80, oil bottom 14.40, ammonia water 2.07, stearic acid 1.80, rosin 3.60, borax 1.08, sodium nitrite 2.52, clean water 50.40.

[0033] The preparation method of this embodiment is the same as that of the embodiment.

Embodiment 3

[0034] Embodiment 3: paraffin wax 10.50, ozokerite 1.50, waste engine oil 12.00, sodium carbonate 1.50, stearic acid 1.50, rosin 3.00, borax 0.90, sodium nitrite 2.10, clean water 42.00.

[0035] The preparation method of this embodiment is the same as that of the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com