Production method of squeezed green tea seed oil

A production method, technology of green tea seed oil, applied in the direction of fat oil/fat production, fat production, etc., can solve the problem of low oil yield, achieve low cost, high nutritional value, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

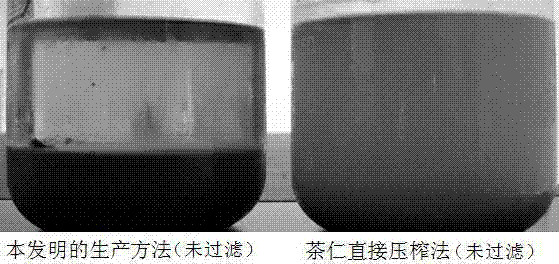

Image

Examples

Embodiment 1

[0030] (1) Collection and drying of green tea seeds: Collect mature green tea seeds, store them indoors for 8 days, and dry them in the sun to a moisture content of less than 12%.

[0031] (2) Shelling of green tea seeds: the green tea seeds treated in step (1) are used to remove the seed shells with a shelling machine to obtain tea kernels.

[0032] (3) Low-temperature drying of tea kernels: The obtained tea kernels are selected to remove impurities, mildew, moth-eaten, and deformed bad tea kernels. The drying temperature is controlled within 60°C, and the moisture content of the dried tea kernels is controlled within the range of 4-8%.

[0033](4) Pre-mixing of tea kernels and rice husks: Mix the dried tea kernels and rice husks in step (3) evenly, and the mixing weight ratio is tea kernels: rice husks = 12:1, and the rice husks are clean and dry rice The moisture content of rice husk is less than 10%.

[0034] (5) Mechanical low-temperature pressing: the mixture obtained ...

Embodiment 2

[0043] (1) Collection and drying of green tea seeds: Collect mature green tea seeds, store them indoors for 7 days, and then air and dry them to a moisture content of less than 12%.

[0044] (2) Shelling of green tea seeds: the green tea seeds treated in step (1) are used to remove the seed shells with a shelling machine to obtain tea kernels.

[0045] (3) Low-temperature drying of tea kernels: The obtained tea kernels are selected to remove impurities, mildew, moth-eaten, deformed bad tea kernels, and the selected tea kernels are air-dried, and the moisture content of the dried tea kernels is controlled. in the 4-8% range.

[0046] (4) Pre-mixing of tea kernels and rice husks: Mix the dried tea kernels and rice husks in step (3) evenly, and the mixing weight ratio is tea kernels: rice husks = 16:1, and the rice husks are clean and dry rice The moisture content of rice husk is less than 10%.

[0047] (5) Mechanical low-temperature pressing: the mixture obtained in step (4) i...

Embodiment 3

[0051] (1) Collection and drying of green tea seeds: Collect mature green tea seeds, store them indoors for 10 days, and dry them in the sun to a moisture content of less than 12%.

[0052] (2) Shelling of green tea seeds: the green tea seeds treated in step (1) are used to remove the seed shells with a shelling machine to obtain tea kernels.

[0053] (3) Low-temperature drying of tea kernels: The obtained tea kernels are selected to remove impurities, mildew, moth-eaten, and deformed bad tea kernels. The drying temperature is controlled within 60°C, and the moisture content of the dried tea kernels is controlled within the range of 4-8%.

[0054] (4) Pre-mixing of tea kernels and rice husks: Mix the dried tea kernels and rice husks in step (3) evenly, and the mixing weight ratio is tea kernels: rice husks = 14:1, and the rice husks are clean and dry rice The moisture content of rice husk is less than 10%.

[0055] (5) Mechanical low-temperature pressing: the mixture obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saponification value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com