Preparation method of polyethyleneimine oil-water separation composite membrane material

A polyethyleneimine oil and polyethyleneimine technology, which is applied in the field of preparation of oil-water separation materials, can solve the problems of difficulty in flammable storage, high cost of sulfur treatment, environmental pollution, etc., so as to increase the anti-oil pollution performance and improve the clustering performance. , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

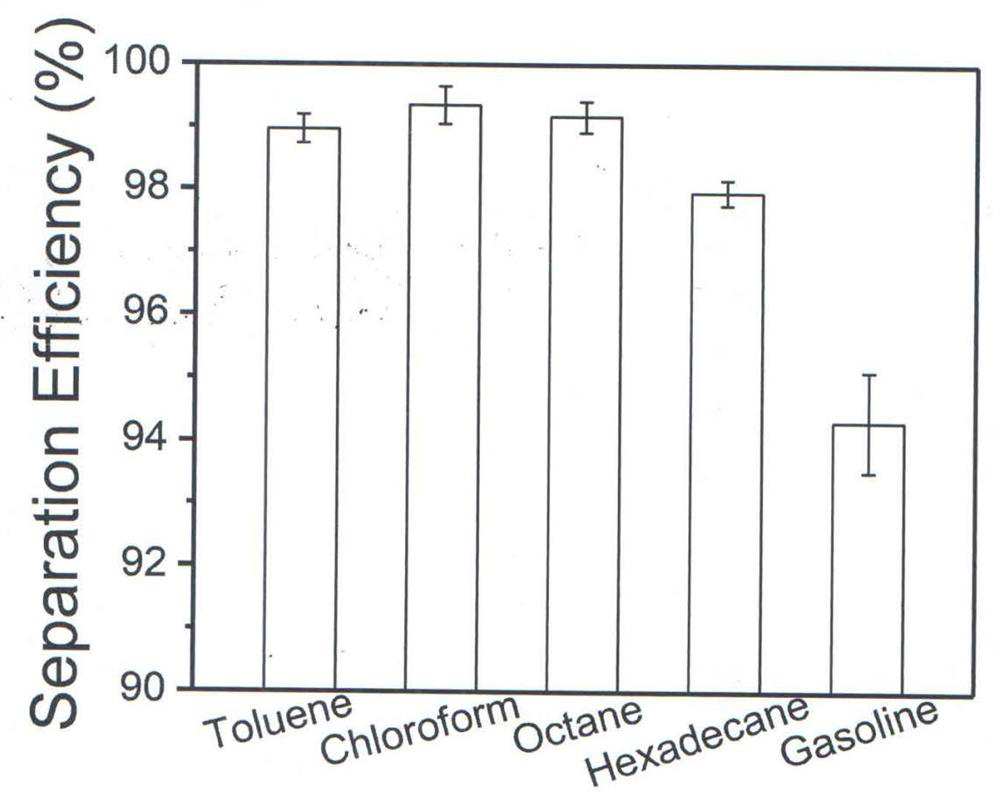

Embodiment 1

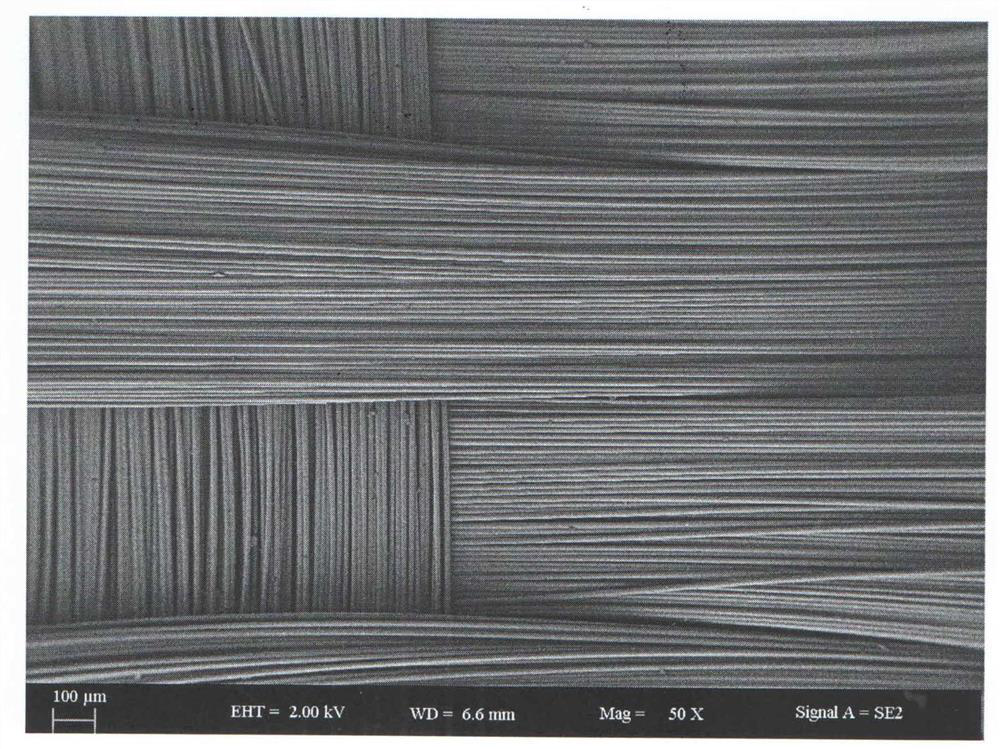

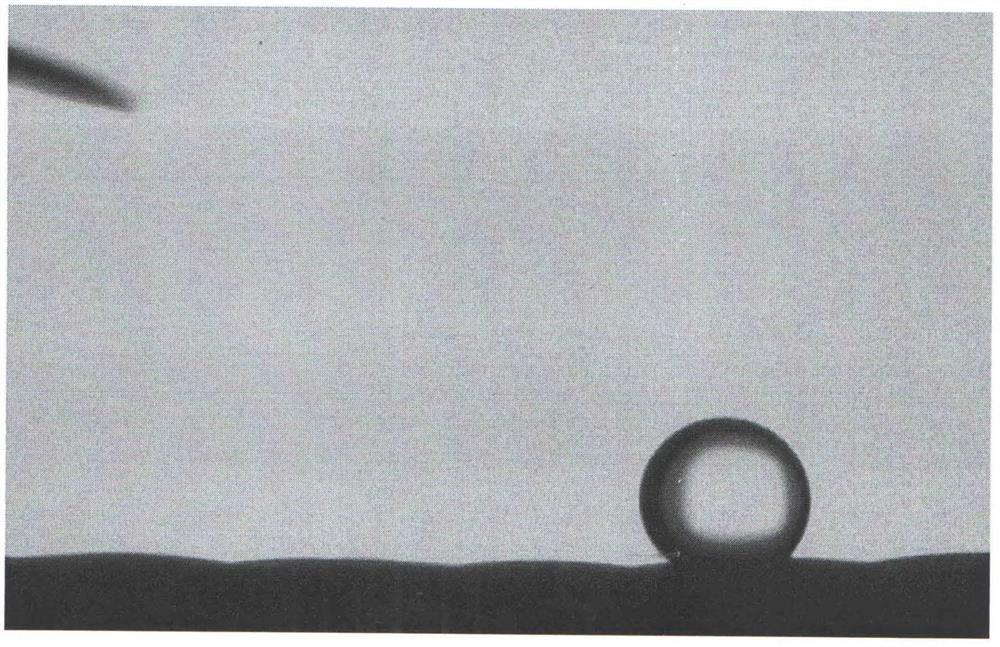

[0027] a. After adjusting the pH of 98mL deionized water to 4 with glacial acetic acid, add 2mL of silane coupling agent KH-550 and hydrolyze it at room temperature for 2 hours to obtain an aqueous solution containing silane coupling agent KH-550. Put the basalt fiber fabric in Put it into an aqueous solution containing silane coupling agent KH-550, soak it at room temperature for 2 hours, and then dry it at a temperature of 120°C for 1 hour to obtain a basalt fiber fabric with amino groups on the surface;

[0028] b. Add 2.5 g of polyethyleneimine with a molecular weight of 1800 to 10 mL of N-methylpyrrolidone solution at room temperature, and magnetically stir until fully dissolved to obtain N-methylpyrrolidone solution containing polyethyleneimine. Soak the dried basalt fiber fabric in N-methylpyrrolidone solution containing polyethyleneimine for 20min, then pick up the fabric and remove excess solution;

[0029] c. Add 0.25 g of elemental sulfur into 10 mL of N-methylpyrro...

Embodiment 2

[0031] a. After adjusting the pH of 98mL deionized water to 4 with glacial acetic acid, add 2mL of silane coupling agent KH-550 and hydrolyze it at room temperature for 2 hours to obtain an aqueous solution containing silane coupling agent KH-550. Put the basalt fiber fabric in Put it into an aqueous solution containing silane coupling agent KH-550, soak it at room temperature for 2 hours, and dry it at 120°C for 1 hour to obtain a basalt fiber fabric with amino groups on the surface;

[0032] b. Add 0.5 g of polyethyleneimine with a molecular weight of 1800 to 10 mL of N-methylpyrrolidone solution at room temperature, and magnetically stir until fully dissolved to obtain N-methylpyrrolidone solution containing polyethyleneimine. Soak the dried basalt fiber fabric in N-methylpyrrolidone solution containing polyethyleneimine for 20min, then pick up the fabric and remove excess solution;

[0033] c. Add 0.25 g of elemental sulfur into 10 mL of N-methylpyrrolidone solution, heat ...

Embodiment 3

[0035] a. After adjusting the pH of 98mL deionized water to 4 with glacial acetic acid, add 2mL of silane coupling agent KH-550 and hydrolyze it at room temperature for 2 hours to obtain an aqueous solution containing silane coupling agent KH-550. Put the basalt fiber fabric in Put it into an aqueous solution containing silane coupling agent KH-550, soak it at room temperature for 2 hours, and dry it at 120°C for 1 hour to obtain a basalt fiber fabric with amino groups on the surface;

[0036]b. Add 1.0 g of polyethyleneimine with a molecular weight of 1800 to 10 mL of N-methylpyrrolidone solution at room temperature, and magnetically stir until fully dissolved to obtain N-methylpyrrolidone solution containing polyethyleneimine. Soak the dried basalt fiber fabric in N-methylpyrrolidone solution containing polyethyleneimine for 20min, then pick up the fabric and remove excess solution;

[0037] c. Add 0.25 g of elemental sulfur into 10 mL of N-methylpyrrolidone solution, heat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com