A preparation method of organosilicon-modified lignin-based strong oil-absorbing material

A lignin-based, oil-absorbing material technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problem of poor surface activity of modified lignin amines, inability to directly use oil-absorbing materials, and oil absorption rate Unsatisfactory and other problems, to achieve the effect of uncomplicated treatment methods, good oil absorption effect, and good oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

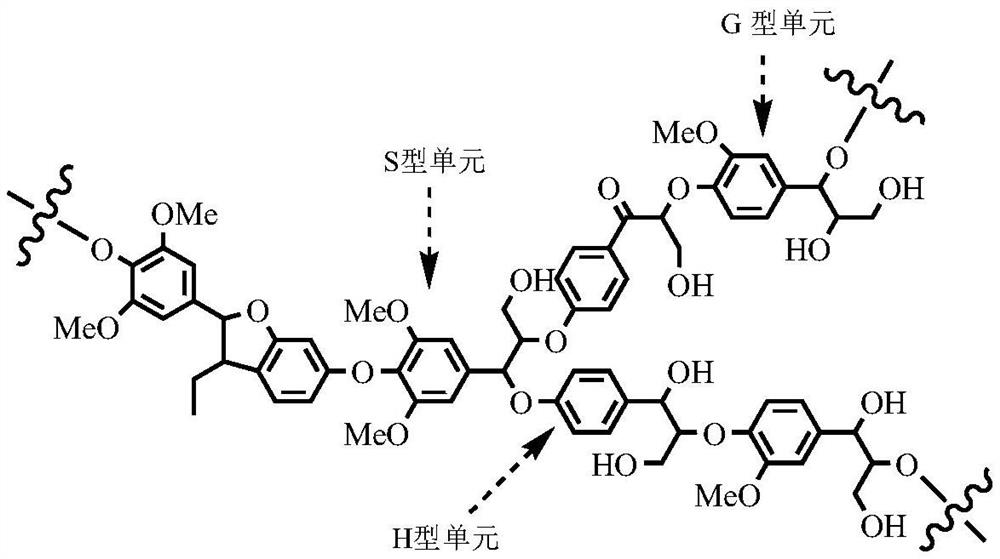

[0031] Preparation of hydroxymethylated lignin: Take a 250mL three-necked flask, dissolve 20g lignin (about 0.1mol in terms of C9 units) in 50mL NaOH solution (concentration 1mol / L), stir well, and slowly drop in 37wt% lignin Formaldehyde solution 8mL (about 0.1mol), stir vigorously, heat up to 50°C, keep warm for 3 hours, pour the reaction solution into 80°C hot distilled water, drop 1mol / L hydrochloric acid solution under stirring state to methylolate Fully analyze lignin, let stand for 3 hours, filter, wash with 0.1mol / L dilute hydrochloric acid first, then wash with distilled water until the pH value is about 7.0, dry at 60°C, grind into fine powder, and then vacuum dry at 80°C The hydroxymethylated lignin was obtained (mass yield 84.2%).

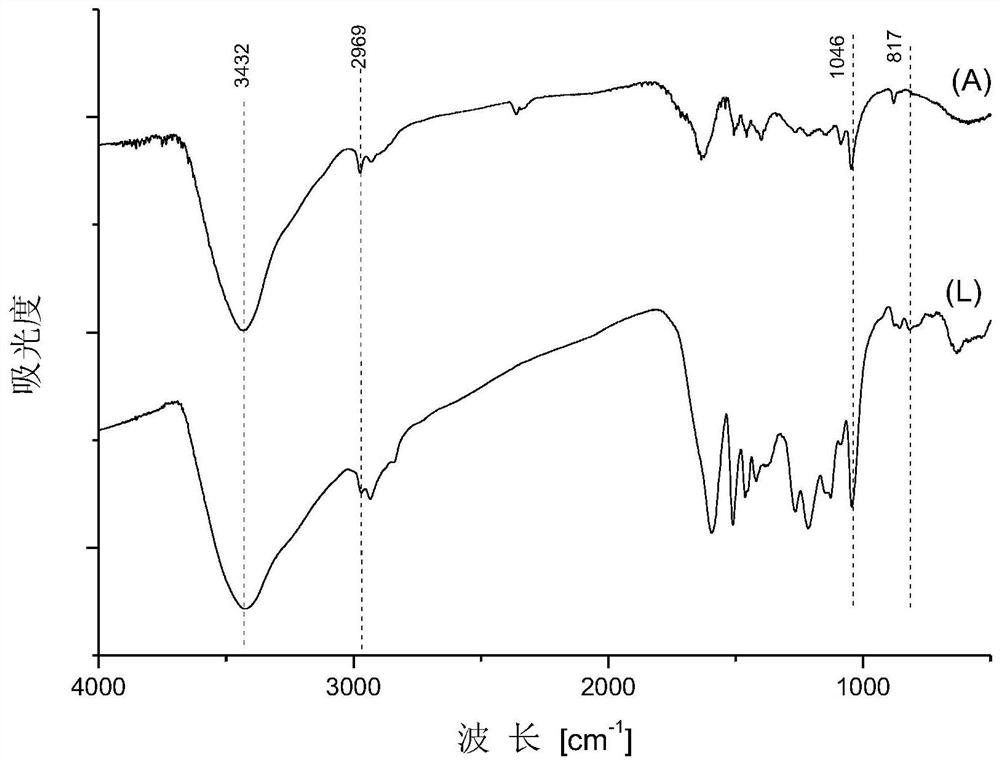

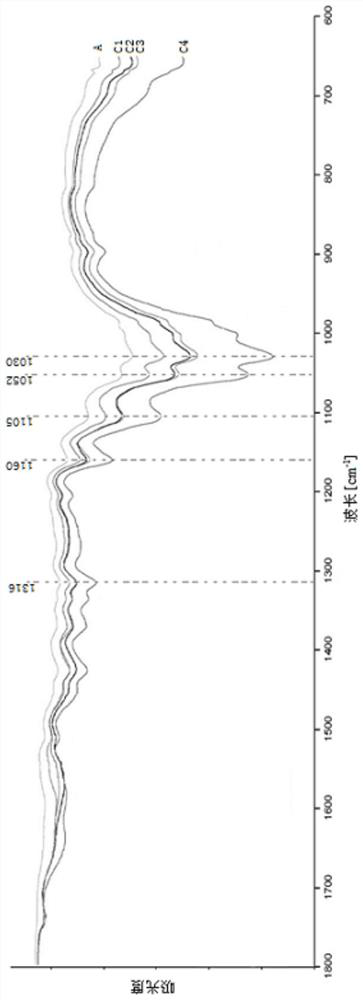

[0032] The obtained hydroxymethylated lignin and the raw material lignin were tested by FT-IR, and the test instrument was a Nicolet Fourier Transform Infrared Spectrometer, and the test method was the KBr tablet method.

[0033] Such ...

Embodiment 2

[0037] The hydrolyzate of hydroxymethylated lignin and 3-aminopropyltriethoxysilane was prepared by the same method as in Example 1.

[0038]Add 1g of hydroxymethylated lignin to 10g of 3-aminopropyltriethoxysilane hydrolyzate, heat to 60°C, stir vigorously, and the reaction time is 24h. After the product was cooled to room temperature, it was filtered, washed with 95 wt% ethanol, washed with water, and dried at 120° C. for 12 hours to obtain silicone-modified lignin-based oil-absorbing material C2 (mass yield 90.4%).

Embodiment 3

[0040] The hydrolyzate of hydroxymethylated lignin and 3-aminopropyltriethoxysilane was prepared by the same method as in Example 1.

[0041] Add 1g of hydroxymethylated lignin to 20g of 3-aminopropyltriethoxysilane hydrolyzate, heat to 60°C, stir vigorously, and the reaction time is 24h. After the product was cooled to room temperature, it was filtered, washed with 95 wt% ethanol, washed with water, and dried at 120° C. for 12 hours to obtain silicone-modified lignin-based oil-absorbing material C3 (mass yield 90.7%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com