Noiseless waste-heat-recoverable commercial oil-gas range

A waste heat recovery and oil-gas stove technology, applied in the field of oil-gas stoves, can solve the problems of high combustion noise and energy waste of ordinary stoves, and achieve the effects of long life, excellent waste heat recovery function, and saving kitchen space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

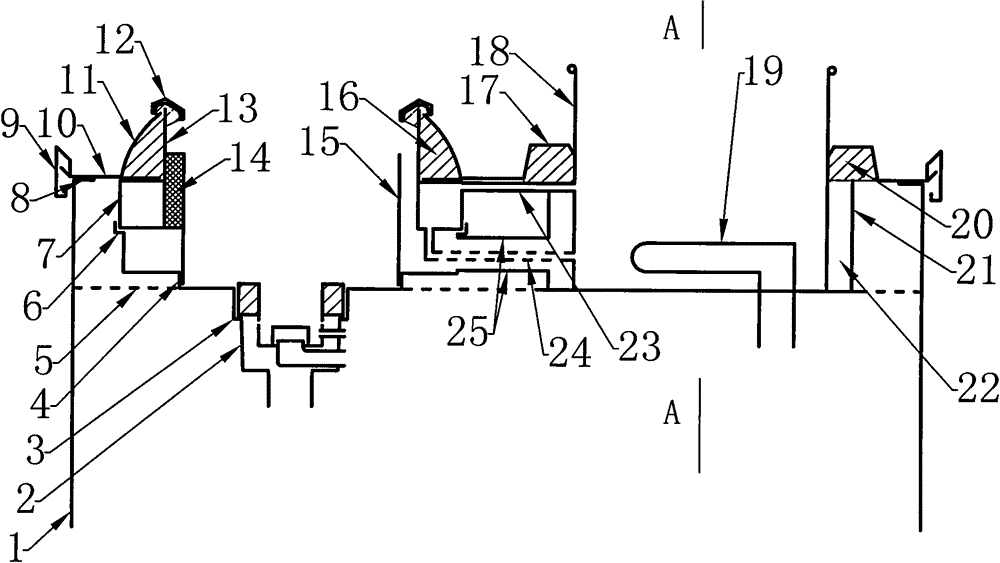

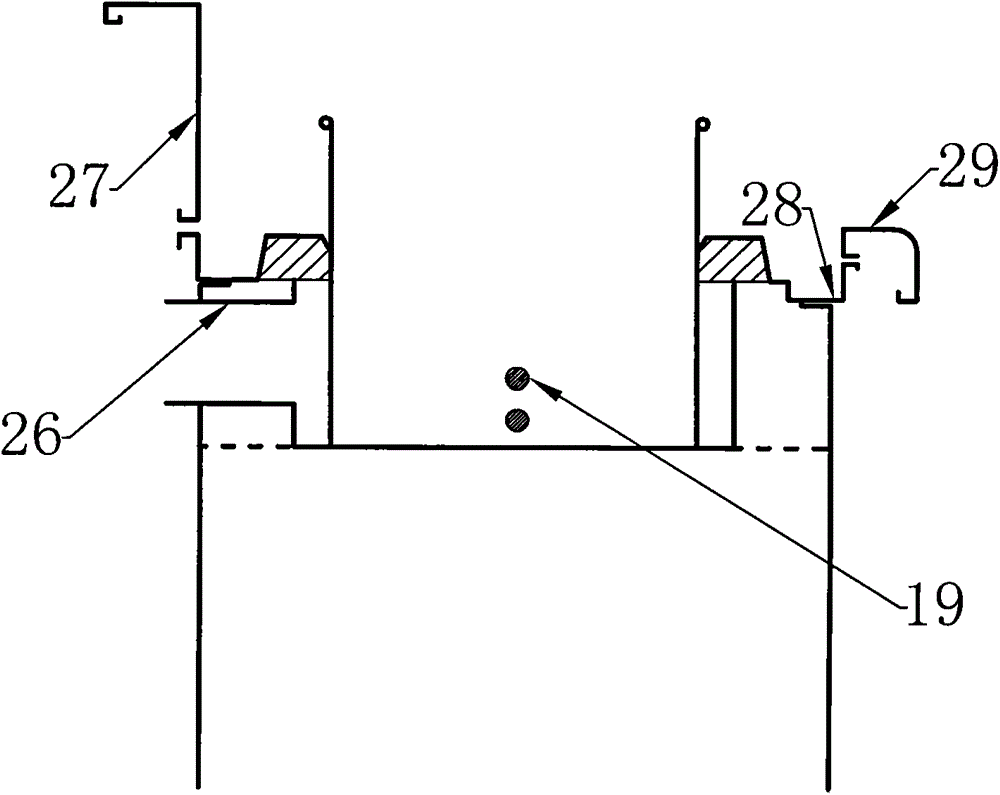

[0021] The accompanying drawings describe the structural form of a noiseless waste heat recovery commercial oil-gas stove. A noiseless waste heat recovery commercial oil-gas stove mainly consists of a bracket, a waste heat recovery device, a base, a fire arresting ring, an annular bucket, an electric heater, and a water bucket. The legs 1, the lower frame 5, and the upper frame 8 together form a bracket; the fixed steps of the waste heat recovery device 6, the fixed steps of the fire stop ring 4, and the fixed steps of the combustion head 3 are connected together to form a base, and the base is integrated casting or integrated The base is fixed on the lower frame 5; the main body 7 of the waste heat recovery device is a hollow metal body whose shape is cylindrical, truncated, prismatic, or truncated; the main body of the waste heat recovery There are wing plates 14 on the inner side of 7, and there are multiple wing plates on the inner side of the main body of the waste heat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com