Concrete healant

A concrete repairing agent and retarding technology, applied in the field of concrete repairing agents, can solve the problems of ordinary polymer-modified cement mortar having no self-leveling performance, unusable concrete repair works, and impermeable concrete, etc. The effect of long construction time and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

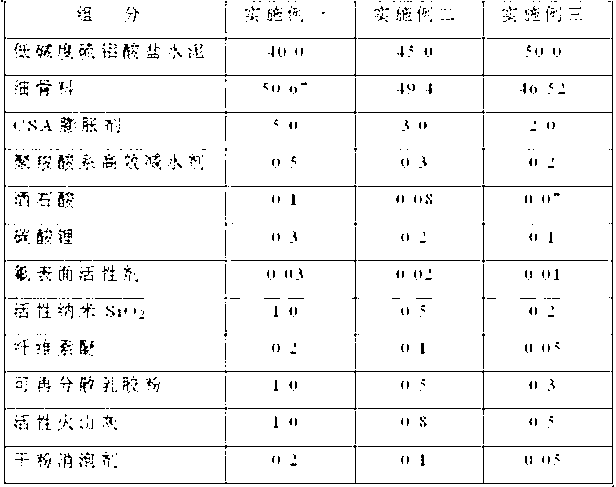

[0051] A concrete repair agent, by weight, comprises the following components:

[0052]

[0053] Among them: low alkalinity sulfoaluminate cement, CSA expansion agent, polycarboxylate superplasticizer, tartaric acid, lithium carbonate, fluorine surfactant, active nano-SiO 2 , cellulose ether (viscosity of 400 centipoise), redispersible latex powder and dry powder defoamer are all commercially available products;

[0054] The fine aggregate is 70~140 mesh river sand.

[0055] The preparation method of the above-mentioned Examples 1 to 3 is: weighing various raw materials according to the above-mentioned proportions, and then mixing them in a mixer until they are evenly stirred.

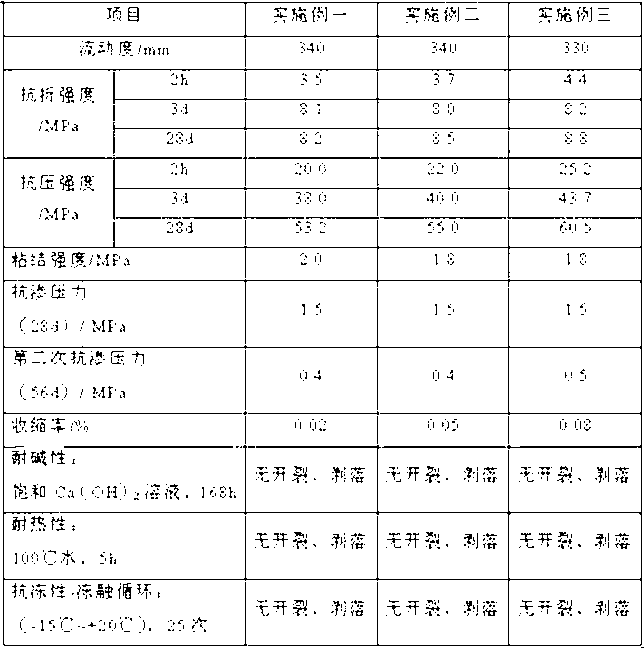

[0056] According to the industry standard JC / T 984-2011 "Polymer Cement Waterproof Mortar", the product performance of the invention is tested, and the specific performance indicators are shown in the following table:

[0057]

[0058] As can be seen from the above table, the concrete repair ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com