Inorganic mineral polymer self-leveling mortar and preparation method thereof

A self-leveling mortar and inorganic mineral technology, applied in the field of building materials, can solve the problems of mine tailings utilization rate of less than 5% and industrial solid waste utilization rate of less than 50%, and achieve good compressive strength and wear resistance, The effect of good surface wear resistance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

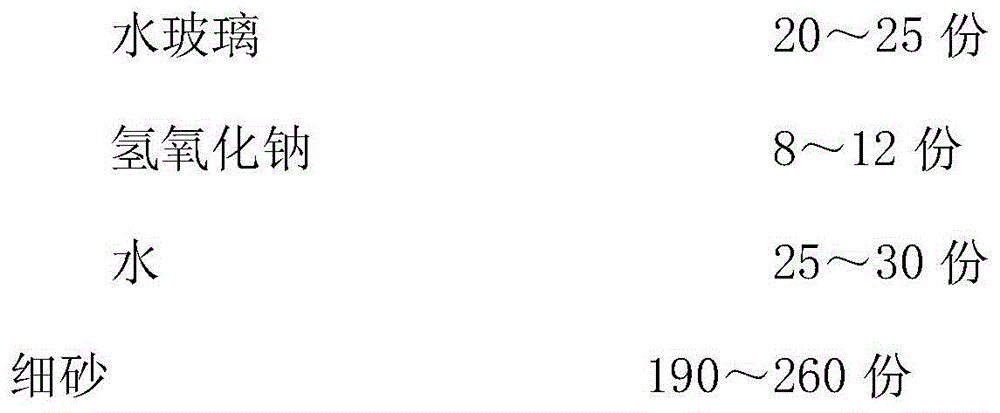

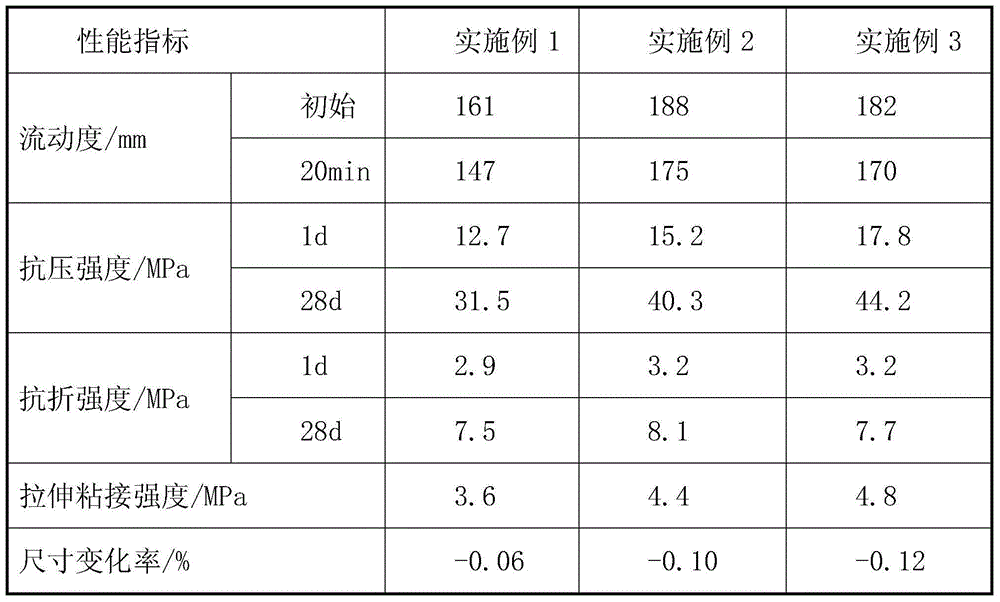

[0057]Embodiment 1: A kind of inorganic mineral polymer self-leveling mortar, according to slag 64, fly ash 14, kaolin 22, water glass 22, sodium hydroxide 9, water 26, fine sand 210, water reducer 0.4, stabilizer 0.06 , prepared with 0.06 parts by weight of the defoamer. The performance test results are shown in Table 1.

Embodiment 2

[0058] Embodiment 2: A kind of inorganic mineral polymer self-leveling mortar, according to slag 70, fly ash 12, kaolin 18, water glass 24, sodium hydroxide 12, water 30, fine sand 250, water reducer 0.5, stabilizer 0.04 , prepared with 0.04 parts by weight of the defoamer. The performance test results are shown in Table 1.

Embodiment 3

[0059] Embodiment 3: A kind of inorganic mineral polymer self-leveling mortar, according to slag 72, fly ash 10, kaolin 18, water glass 25, sodium hydroxide 13, water 29, fine sand 240, water reducer 0.8, stabilizer 0.07 , prepared with 0.08 parts by weight of the defoamer. The performance test results are shown in Table 1.

[0060] Table 1 Example performance test results

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com