Motor stator winding, stator using same and motor

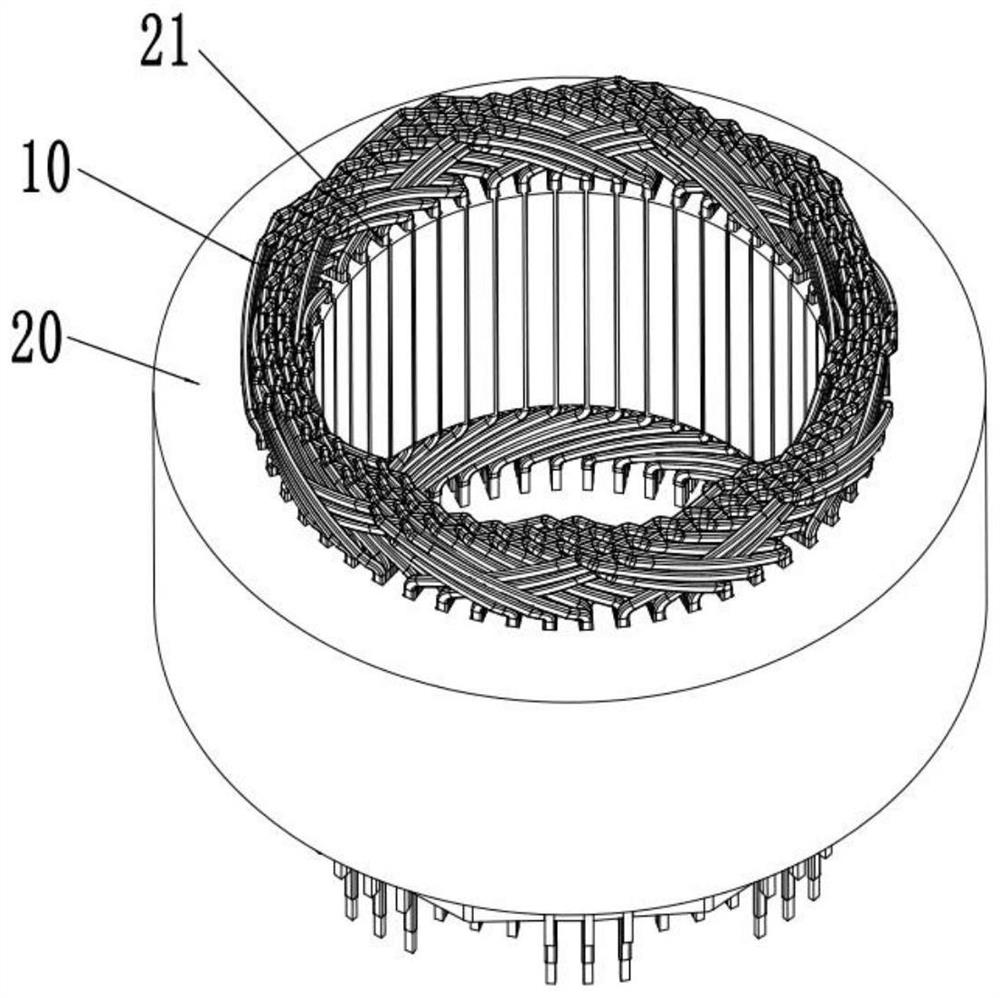

A motor stator and stator winding technology, which is applied to the shape/style/structure of winding and winding conductors, electric components, etc., can solve the problems of inconsistent twisting directions of hairpin coils, complex arrangement of stator windings, and low processing efficiency. The effect of reducing the complexity of the manufacturing process, increasing the sustainable operating power, and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

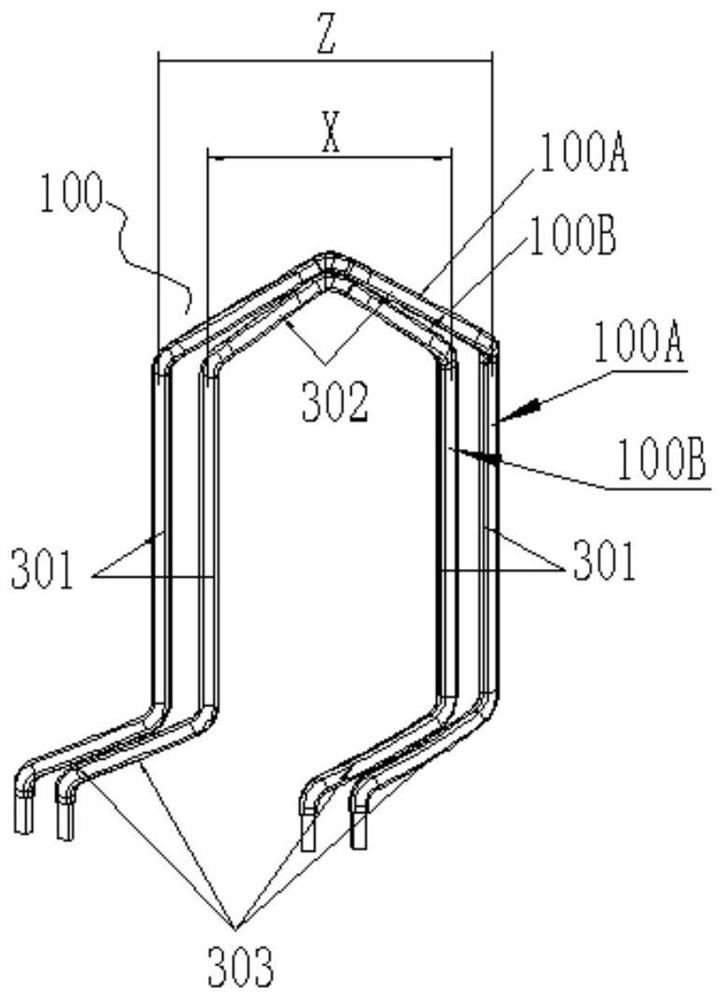

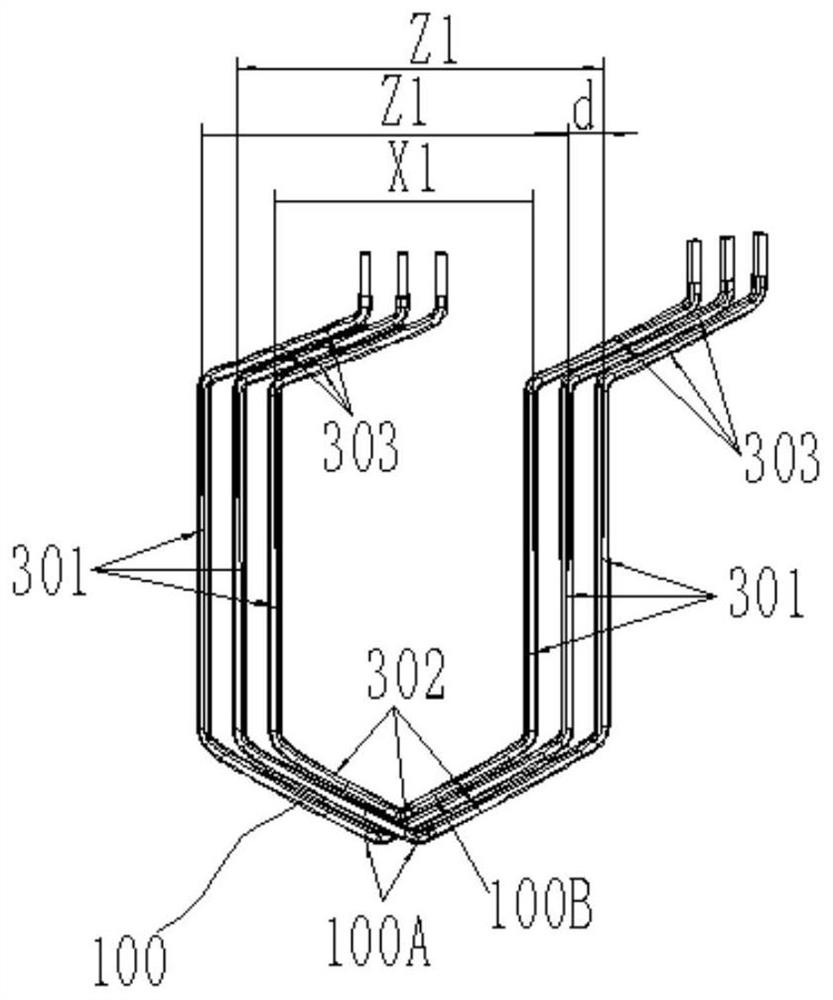

[0129] Embodiment 1: as Figure 9 As shown, the number of 21 per pole and each phase slot is 2, and the 2 branches are arranged in series, the first coil group is on the same layer (7, 5) + the first second coil group is at a full distance (6) + the second second Coil group full distance (6) + the fourth coil group on the same layer (7, 5); the number of layers is 6, two second coil groups are arranged adjacently, and the second second coil group is located in the radial direction of the stator core The pitch between a welding end 303 of the conductor of the 4th layer and a welding end 303 of the conductor of the third layer in the radial direction of the stator core in the first second coil group is a long pitch of 7;

Embodiment 2

[0130] Embodiment 2: as Figure 10 As shown, the number of 21 per pole and each phase slot is 2, and the 2 branches are arranged in series, the first coil group is on the same layer (7, 5) + the first second coil group is at a full distance (6) + the second second Coil group full distance (6) + the fourth coil group on the same layer (7, 5); the number of layers is 6, two second coil groups are arranged adjacently, and the second second coil group is located in the radial direction of the stator core The pitch between a welding end 303 of the conductor of the 4th layer and a welding end 303 of the conductor of the third layer in the radial direction of the stator core in the first second coil group is short pitch 5;

Embodiment 3

[0131] Embodiment 3: as Figure 11 As shown, the number of 21 per pole and each phase slot is 2, and the 2 branches are arranged in series, the first coil group is on the same layer (7, 5) + the first second coil group is at a full distance (6) + the second second Long and short distances of the coil group (7, 5) + the same layer of the fourth coil group (7, 5); the number of layers is 6, two second coil groups are arranged adjacently, and the second second coil group is located in the stator core The pitch between a welding end 303 of the conductor on the fourth layer in the radial direction and a welding end 303 of the conductor on the third layer in the radial direction of the stator core in the first second coil group is a long pitch of 7;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com