Sealing arrangement

A sealing device and sealing lip technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as difficult adjustment and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

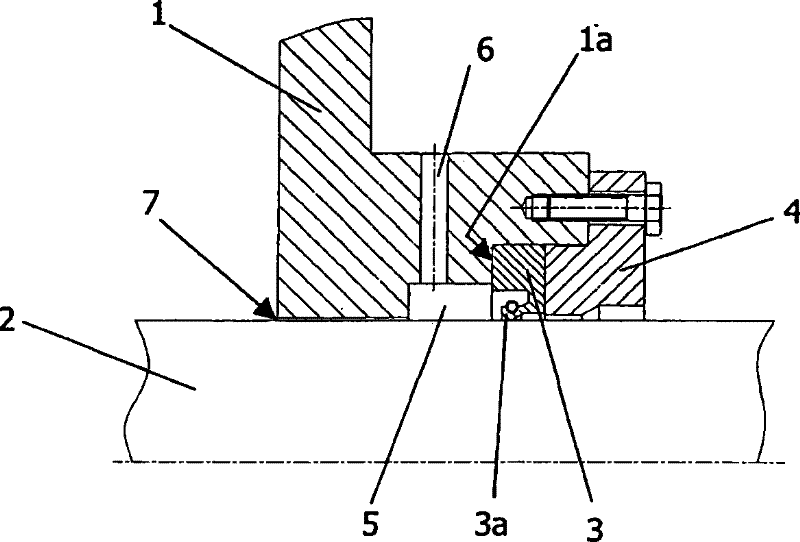

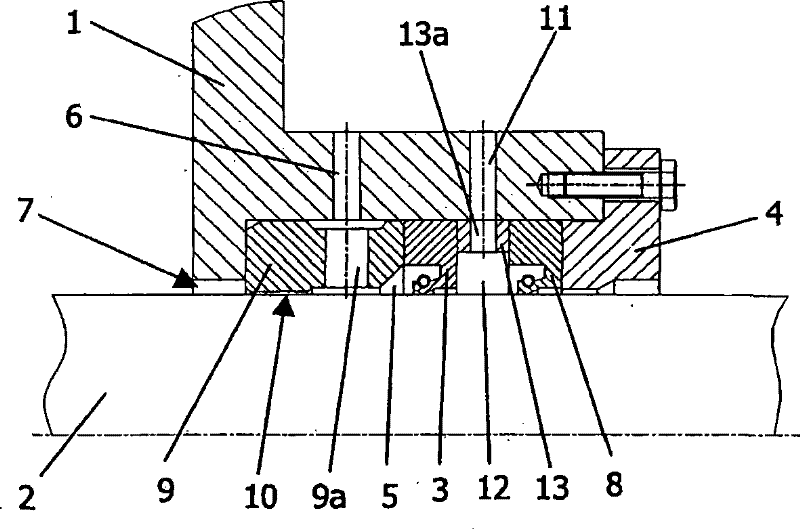

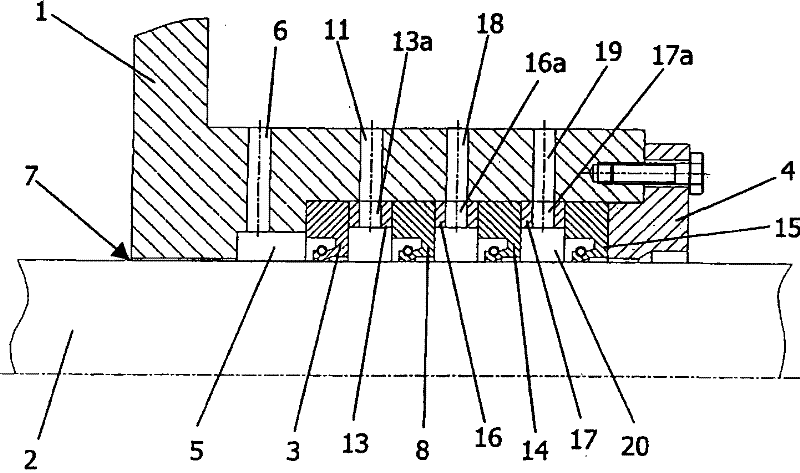

[0023] figure 1 A sectional view is shown of a housing 1 with a sealing device according to the invention intended to seal the introduction of a rotating shaft 2 through an opening in the housing 1 . In the very simple example shown, the sealing arrangement comprises a single-lip seal 3 with a sealing lip 3a facing the area normally under higher pressure.

[0024] The lip seal 3 is placed on the protrusion 1 a of the opening in the housing 1 and is pressed against the protrusion 1 a by the pressure ring 4 . A circumferential grooved area 5 is formed between the protrusion 1 a and a part of the opening of the housing 1 surrounding the shaft 2 with a narrow gap. A hole 6 in the housing 1 leads to this area 5 on said side of the lip seal 3 which normally faces the higher pressure, so that the area 5 can be connected to a pressure source. The medium used for pressurization is preferably a medium already used in the process or a medium present on the side which is usually at a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com