Gas supercharger

A gas booster and booster chamber technology, which is applied to fluid pressure converters, mechanical equipment, etc., can solve the problems of ineffective utilization of gas pressure, low energy utilization, large volume, etc., and achieves simple structure, wide application, smooth motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

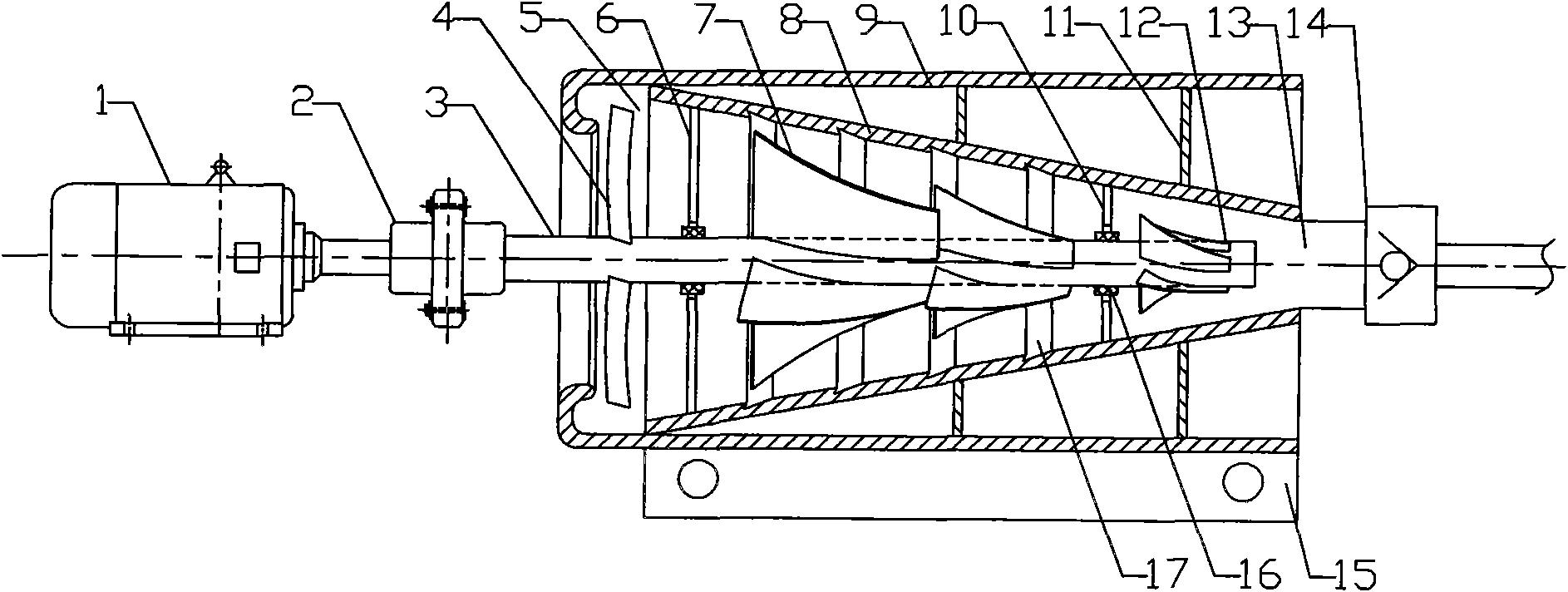

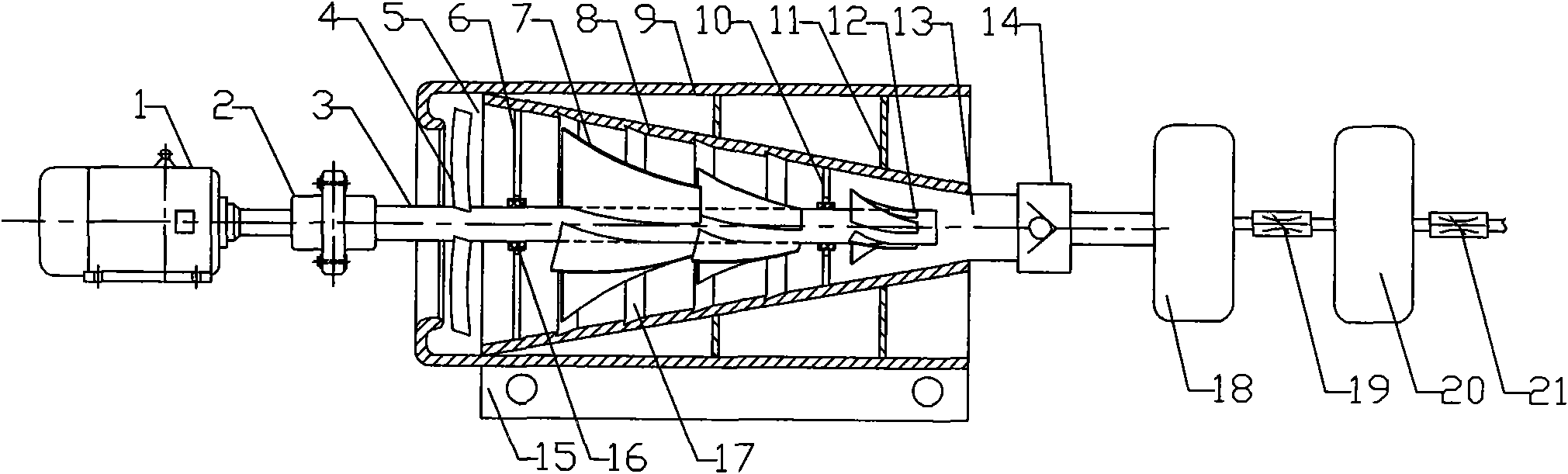

[0024] Embodiment 1: for separating mixed gas

[0025] The power machine 1 drives the power transmission shaft 3 to rotate through the power connection device 2, and the gas on the power transmission shaft 3 is introduced into the paddle device 4, the semi-trapezoidal paddle device 7, and the gas export paddle device 12 rotates synchronously with the power transmission shaft 3. The gas is introduced into the paddle device 4 to introduce the gas into the conical plenum housing 8 through the gas inlet 5, and the gas introduction amount can be adjusted by adjusting the angle and cross-sectional area of the blades. The left end of the cylindrical outer support housing 9 The U-shaped groove forms an annular recirculation chamber around the gas inlet paddle device 4 to prevent the outward diffusion of a small amount of introduced gas and improve energy utilization. The semi-trapezoidal paddle device 7 rotates while exerting force on the gas , so the gas at the large opening end of...

Embodiment 2

[0026] Example 2: Liquefaction system for corrosive gases

[0027] Process the working contact surface of the parts of the present invention by a simple method to make it a corrosion-resistant gas booster, and use the pressurization step of the embodiment of the invention 1 to diethyl ether ((C 2 h 5 ) 2 O), hydrogen sulfide (H 2 S), Chlorine (Cl 2 ) or nitrogen dioxide (NO 2 ) and other flammable and explosive toxic gases are pressurized, then liquefied into liquids, sealed and stored at low temperature, and the liquefaction method is used to compress the corrosive gases for storage and transportation in industrial applications, or use this method to recycle or effectively Treatment of waste gas that pollutes the atmosphere from industrial production.

Embodiment 3

[0028] Embodiment 3: for temperature regulation system

[0029] Also use the present invention to also ammonia (CH 3 ) is pressurized to convert it into liquid ammonia for easy storage and transportation; while ammonia gas (CH 3 ) The liquefaction or gasification will absorb and generate a lot of heat, so the temperature can be adjusted by constantly adjusting its pressure, changing its state of existence, and making it absorb or release a lot of heat.

[0030] In addition, the present invention can also be widely used in the fields of power generation systems, generator systems, liquid-gas mixing systems, gas delivery systems, vacuum systems, etc.; or add a sealable flange outside the cylindrical outer support shell 9, It can effectively reduce energy consumption, reduce production cycle and improve production efficiency when used in fields that require sealing production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com