Orange segment type micro-porous aeration system

A microporous aeration and orange segment technology, which is applied in the direction of sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of reducing process production capacity, poor aeration stability, Increase maintenance costs and other issues, achieve independence and high reliability, cost savings, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

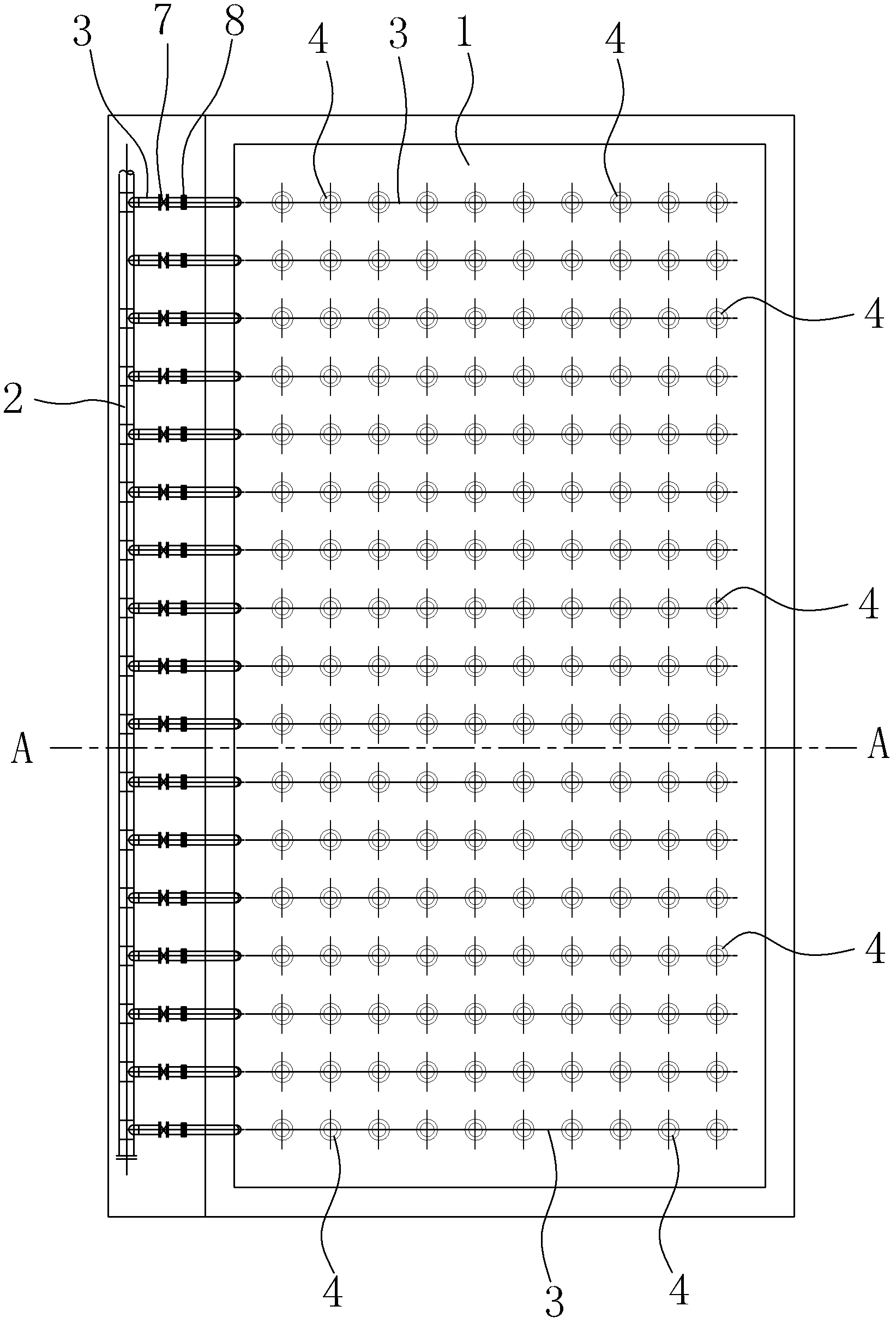

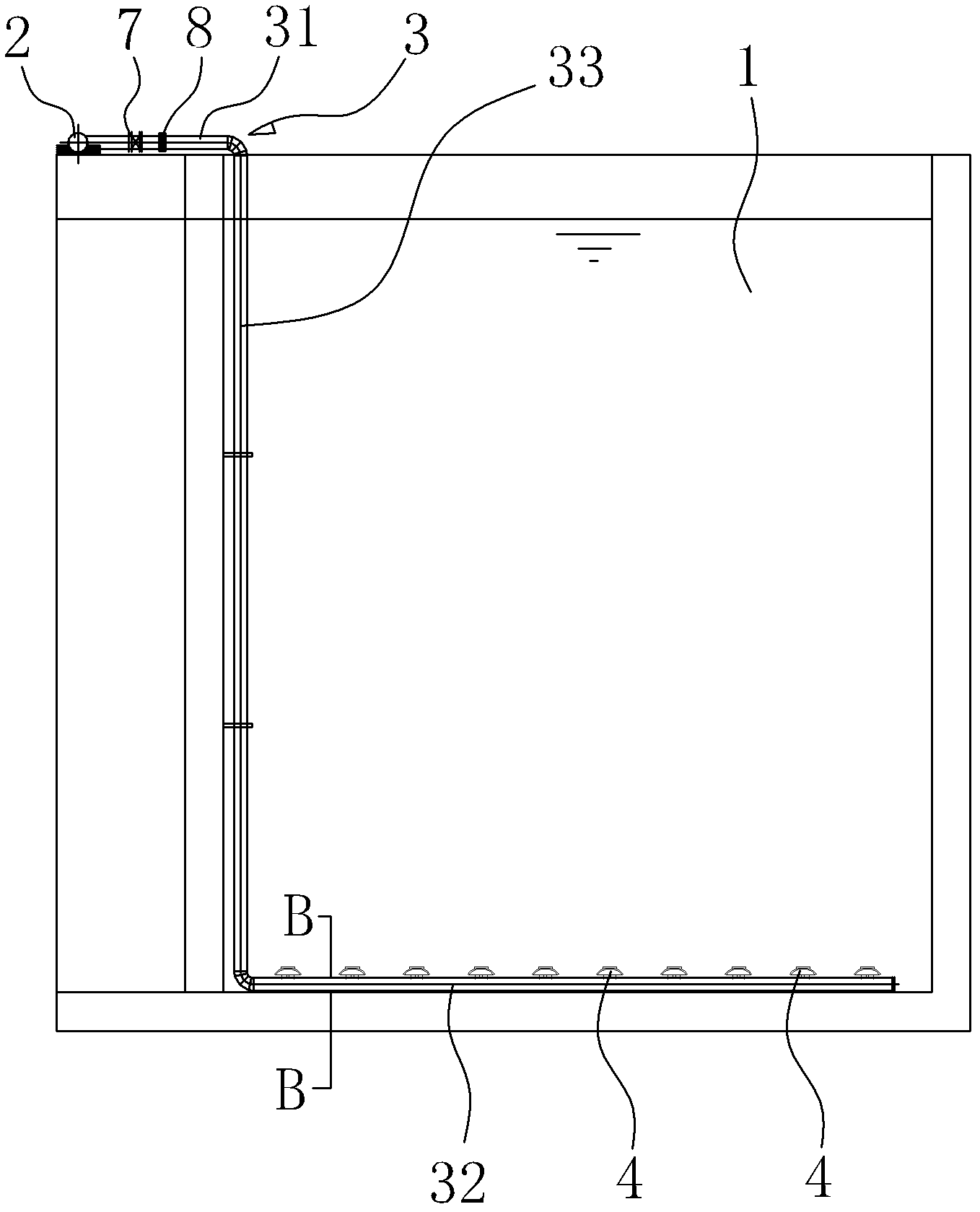

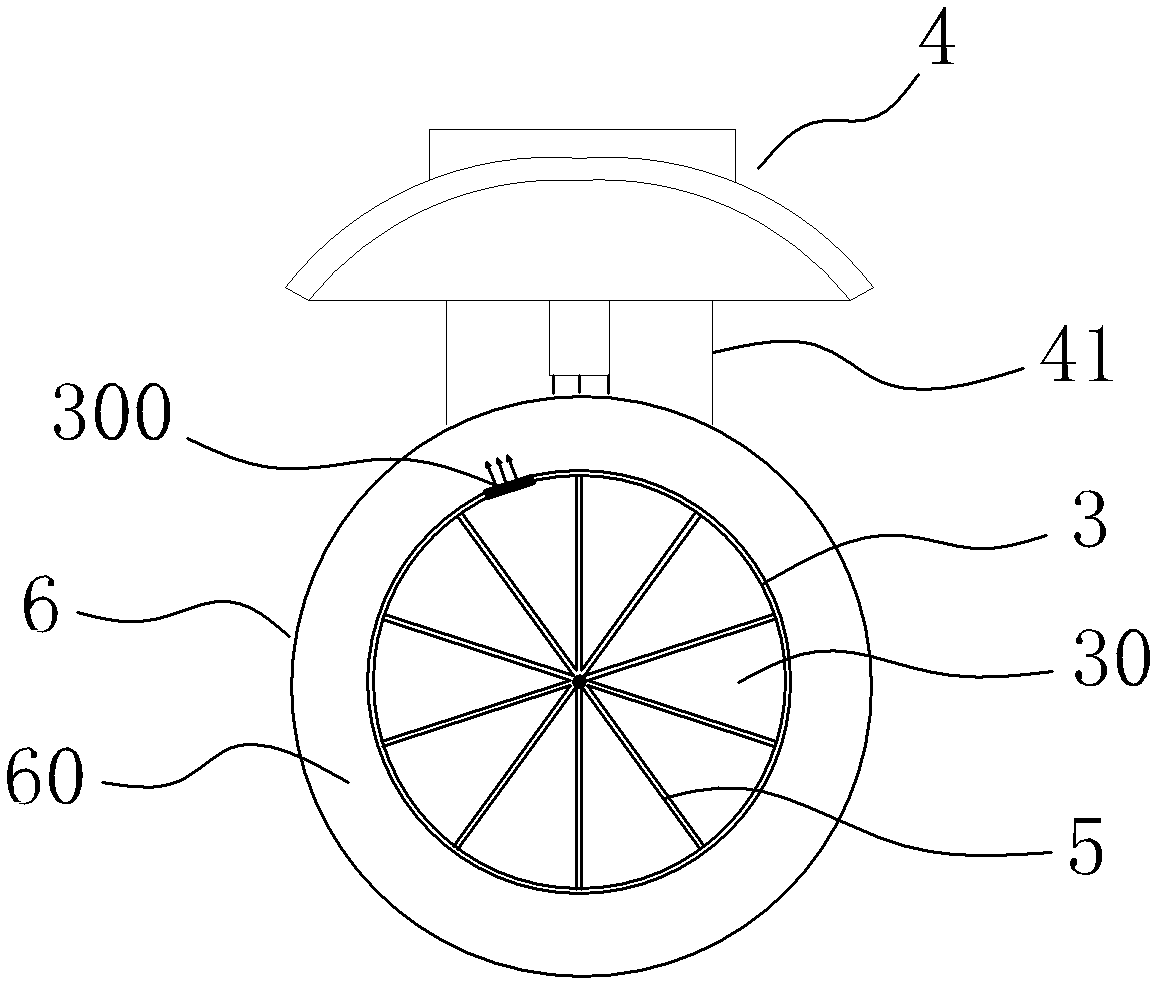

[0029] See Figure 1-4 As shown, an orange petal type microporous aeration system includes: a reaction tank 1, an aeration main pipe 2 fixedly installed on the reaction tank 1, a plurality of aeration pipes evenly installed on the aeration main pipe 2 Branch pipes 3 and a plurality of aeration pans 4 installed on each aeration branch pipe 3, the lumen of the aeration branch pipe 3 is evenly divided into several cavities by a partition 5, forming several cross-sectional shapes similar to orange petals Shaped orange segment pipe 30; each aeration pan 4 and orange segment tube 30 are provided with corresponding numbers, so that one orange segment tube 30 can control one aeration pan 4.

[0030] Specifically, the aeration branch pipe 3 is in the shape of a "Z", which includes an upper branch pipe 31 communicating with the aeration main pipe 2, a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com