Full-automatic drill bit replacing type perforating machine

A technology for changing drill bits and punching machines, which is used in driving devices, positioning devices, feeding devices, etc., can solve the problems of wasting human resources, difficult assembly, and high costs, and achieve the effects of liberating labor, improving efficiency, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

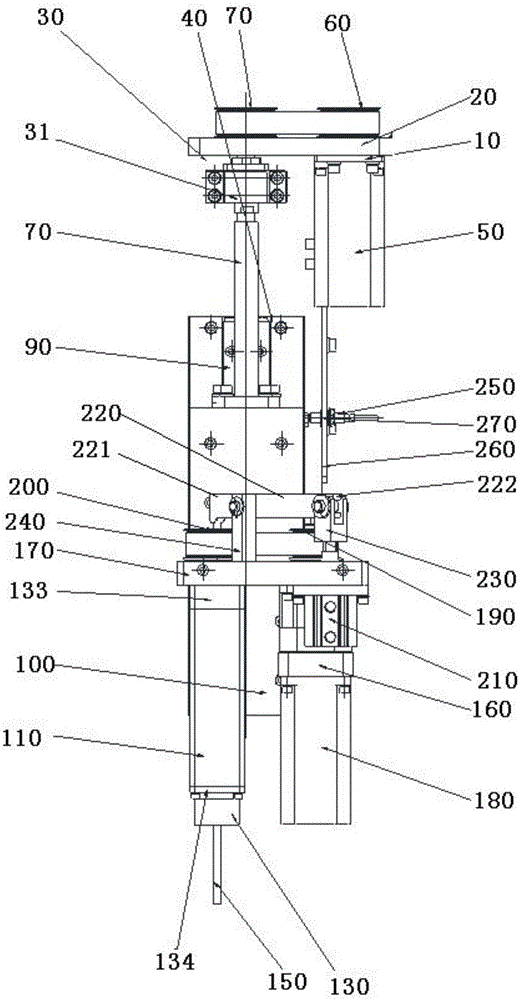

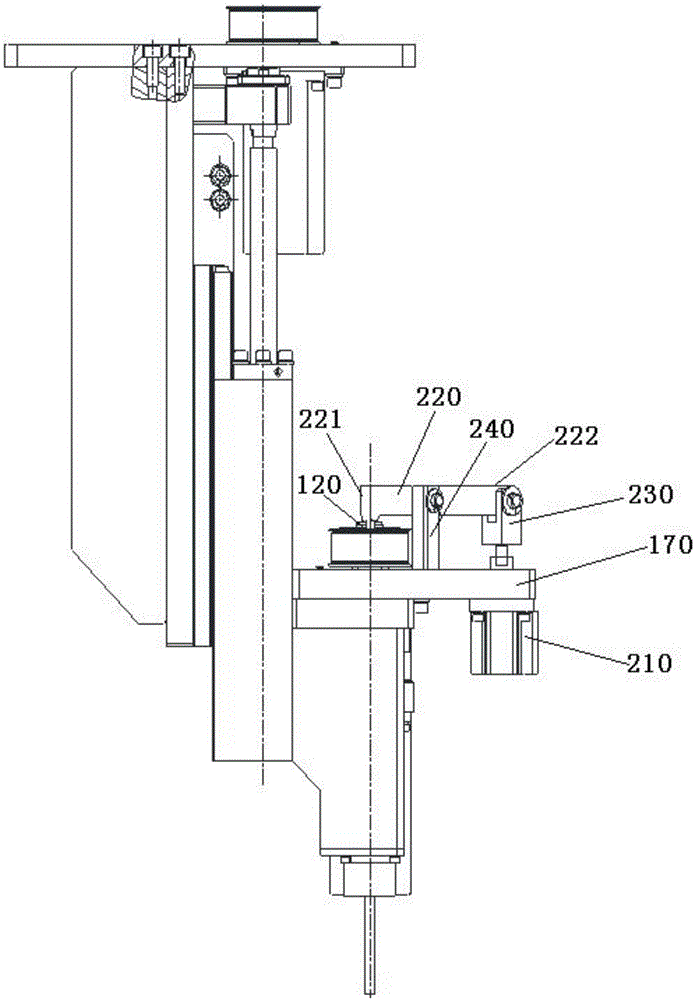

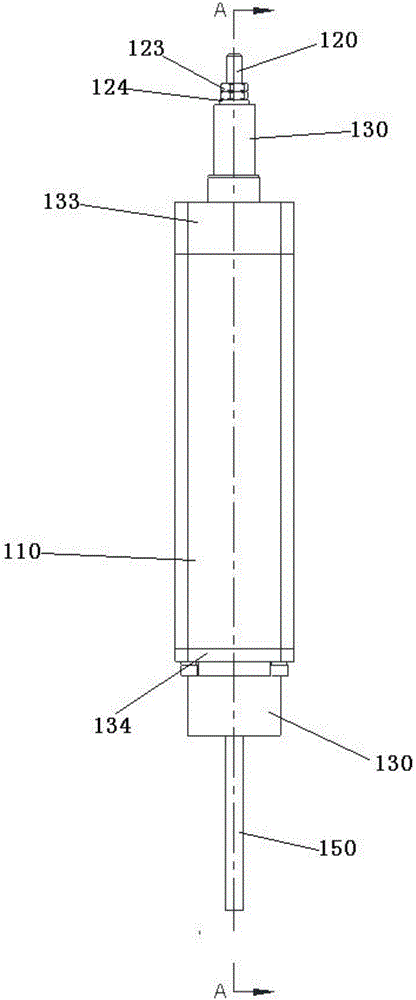

[0048] The invention discloses a full-automatic drilling machine device for changing drill bits, which includes a drilling head, a rotating mechanism that drives the drilling head to rotate and punch holes, a disassembly mechanism that realizes the automatic disassembly of the drill bit on the drilling head, and realizes the drill bit on the drilling head. Mounting mechanism for automatic installation.

[0049] see figure 1 As shown, the disassembly mechanism includes a first motor mounting plate 10, an upper assembly plate 20, an assembly base plate 30, a slider base plate 40, a first servo motor 50, a first synchronous pulley 60, a second synchronous pulley 70, and a ball screw 80. Cross roller guide rail 90 and slider 100; the slider base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com