Device for automatically printing colored rings on shells

A shell and color ring technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems that affect the quality of the products, the delivery of qualified products on schedule, the difficulty of ensuring the quality of hand-printed color rings, and the inability to meet mass production, etc., to achieve the guarantee The effect of product quality and qualified product delivery on schedule, meeting mass production, and meeting product design and process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

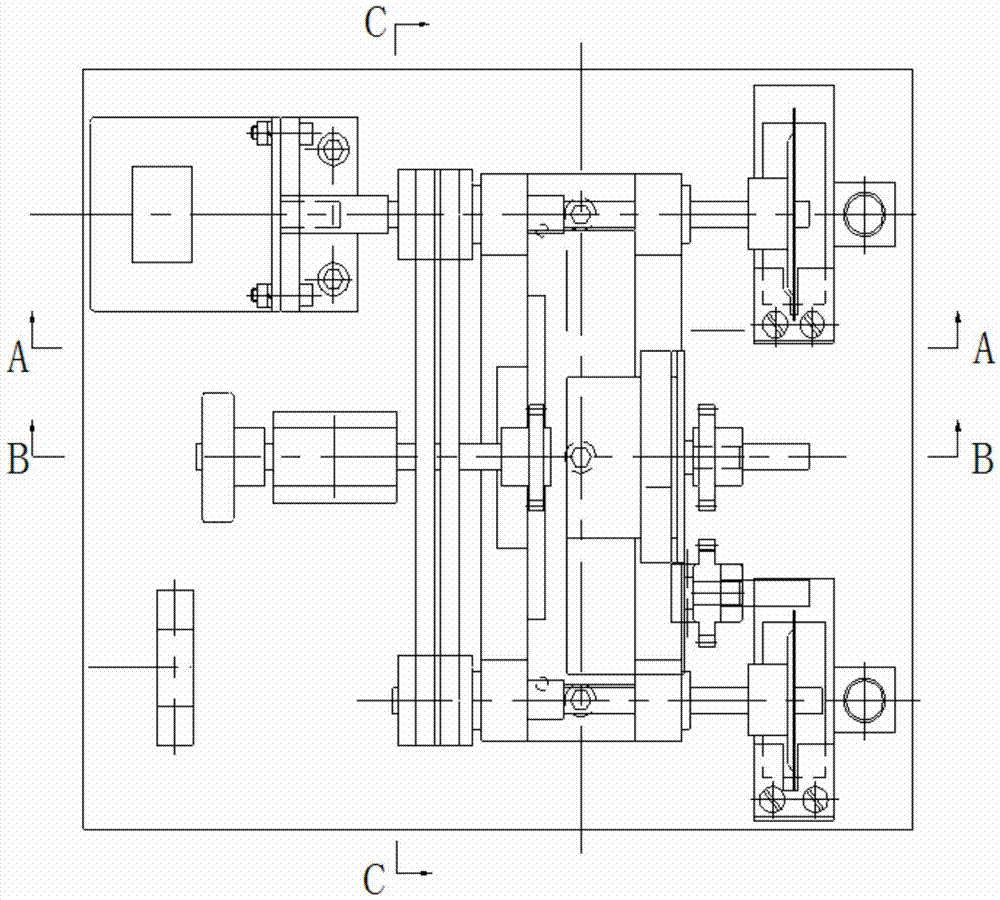

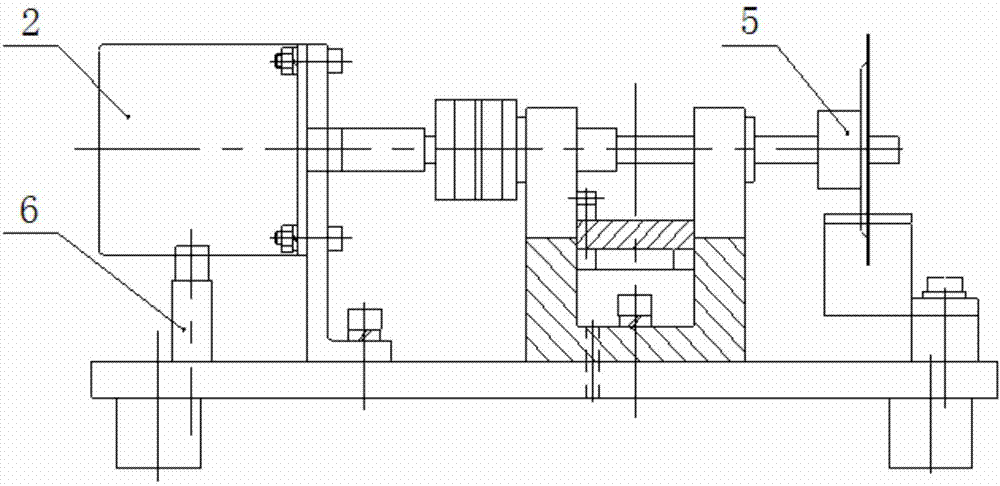

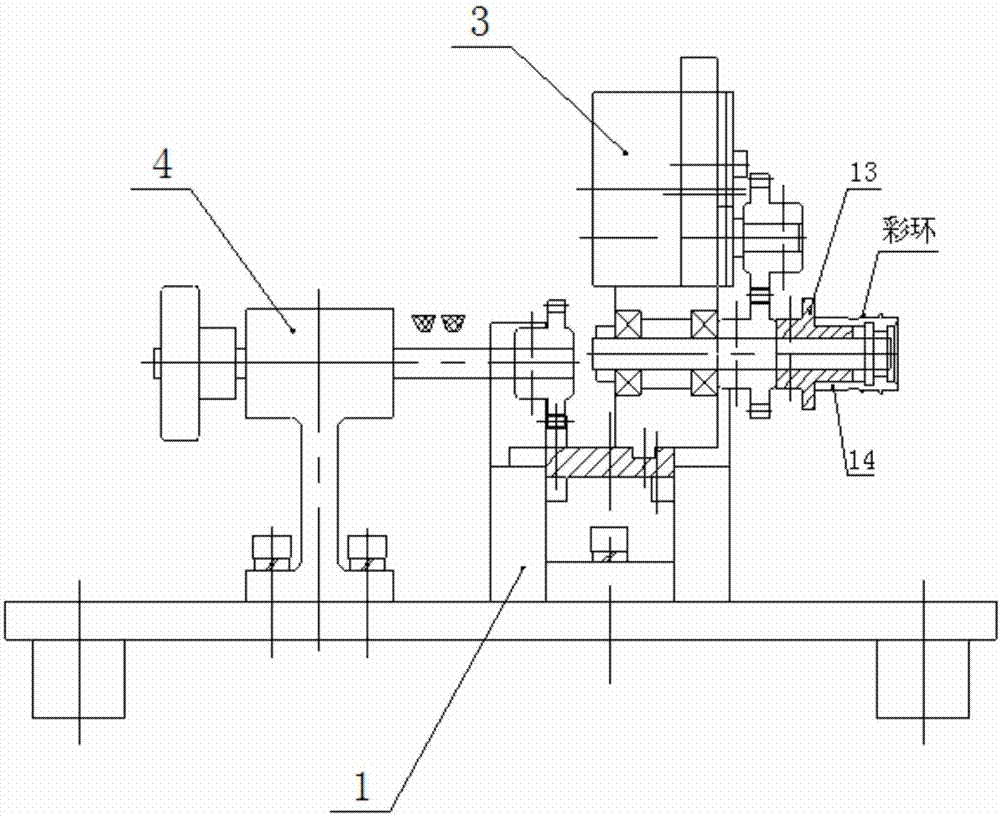

[0038] The shell automatic printing ring equipment is composed as follows: body part 1, main transmission system 2, shell rotation system 3, longitudinal movement system 4, ink coating part 5 and electrical part 6; the main transmission system 2, shell The body rotation system 3, the longitudinal movement system 4 and the ink coating part 5 are all located on the body part 1, the electric part 6 forms an electrical connection with the main transmission system 2 and the housing rotation system 3, and the main transmission system 2 and the ink coating part 5 Connected, the shell rotation system 3 is connected with the product shell 6 .

[0039] The body part 1 is constituted as follows: a sliding plate 11, a base 12, a base 13, a pillar 14 and an axle sleeve 15; the sliding plate 11 is located in the sliding groove of the base 12; Above, the pillar 14 is positioned and fastened on the bottom of the base 13 , the bushing 15 is fastened in the shaft hole of the machine base 2 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com