Metallurgical slag pot trunnion casting method

A technology of metallurgical slag and trunnions, which is applied in the field of metallurgy, can solve problems such as the surrounding of trunnions and the structure of trunnions are not dense, the structure of trunnions 4 is not dense enough, and the tolerance of trunnions 4 cannot be guaranteed, so as to save the machining process , short production cycle and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] A metallurgical slag tank trunnion inlay casting method, which is to cast the processed trunnion on the slag tank body when casting the slag tank body to make the slag tank with the trunnion inlaid.

[0030] see Figure 1-Figure 7 , the method includes the following steps:

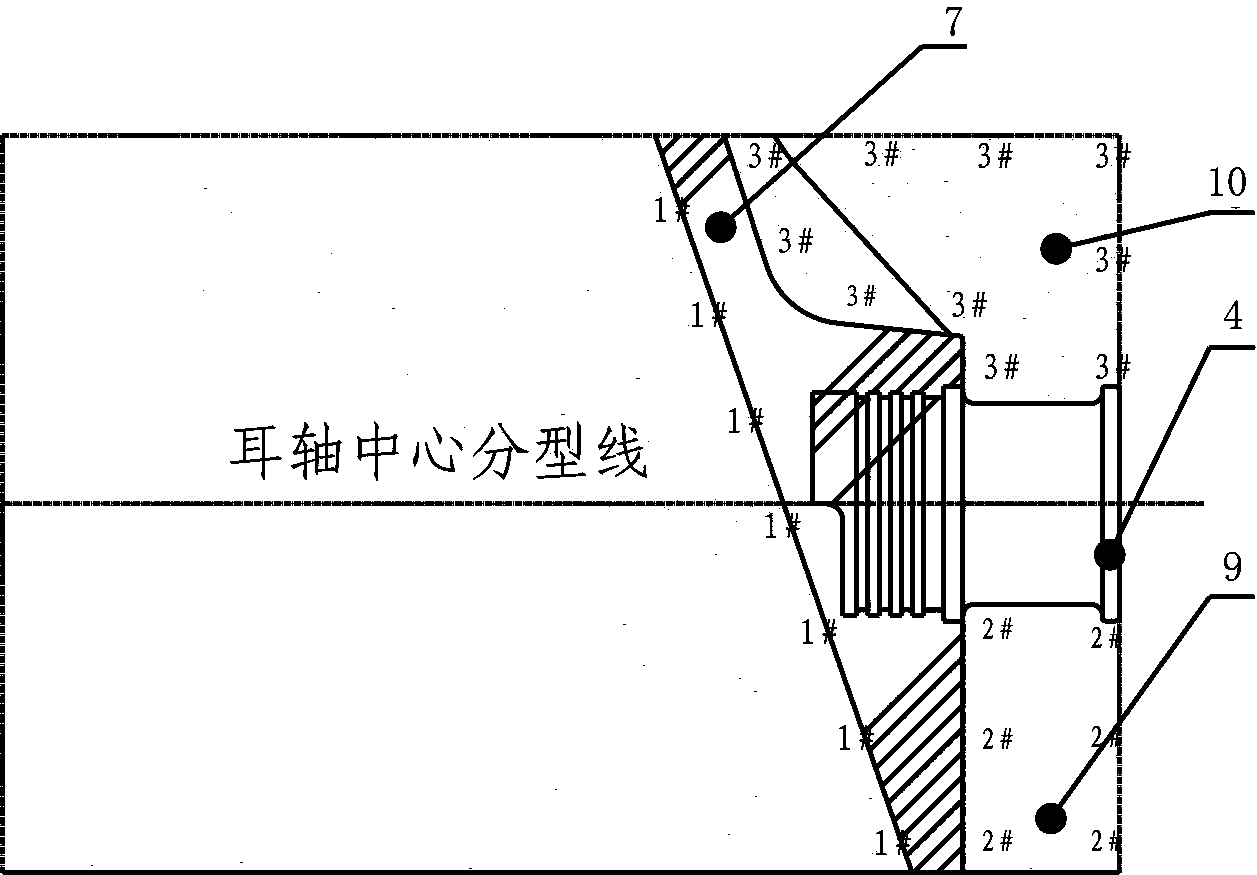

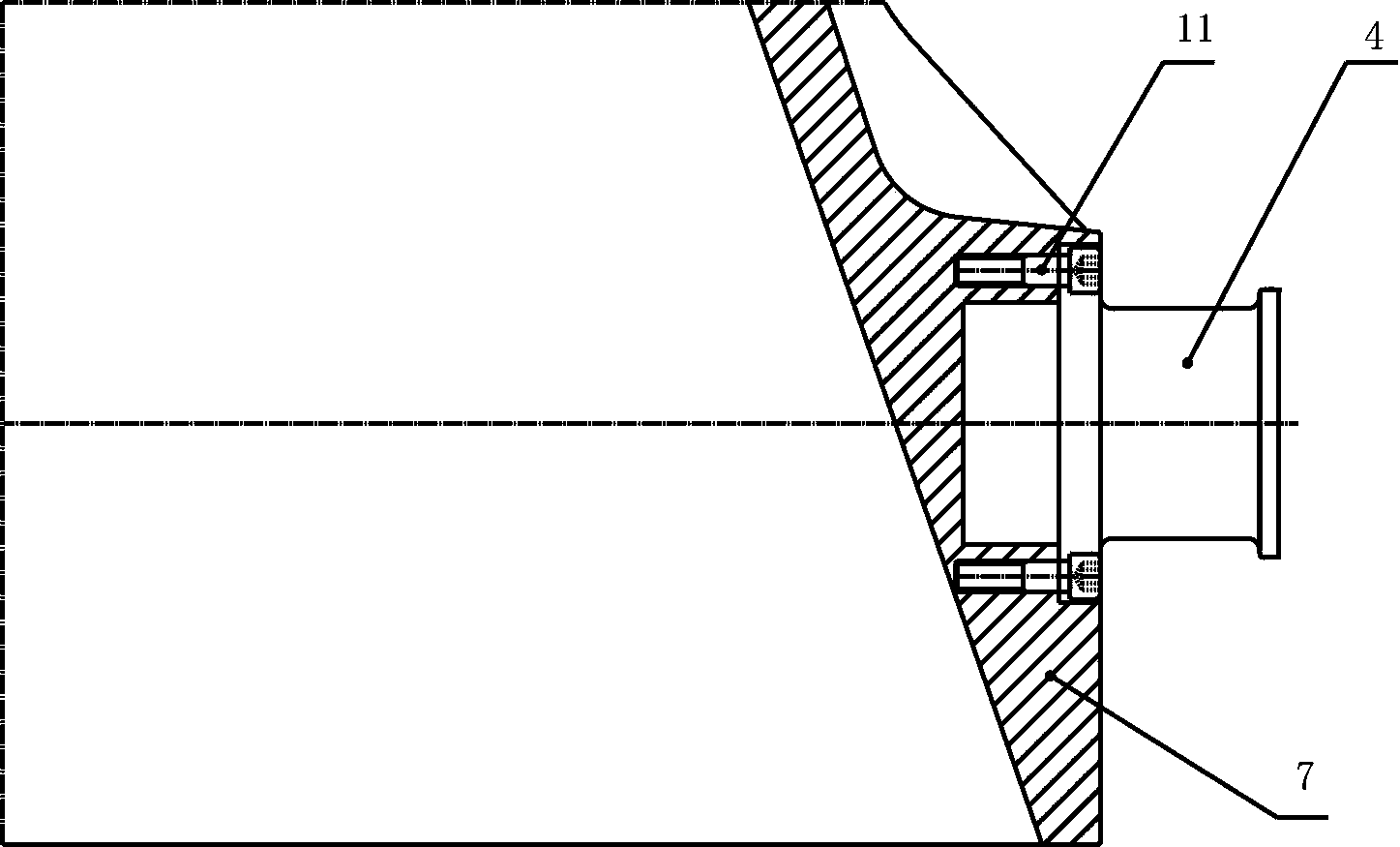

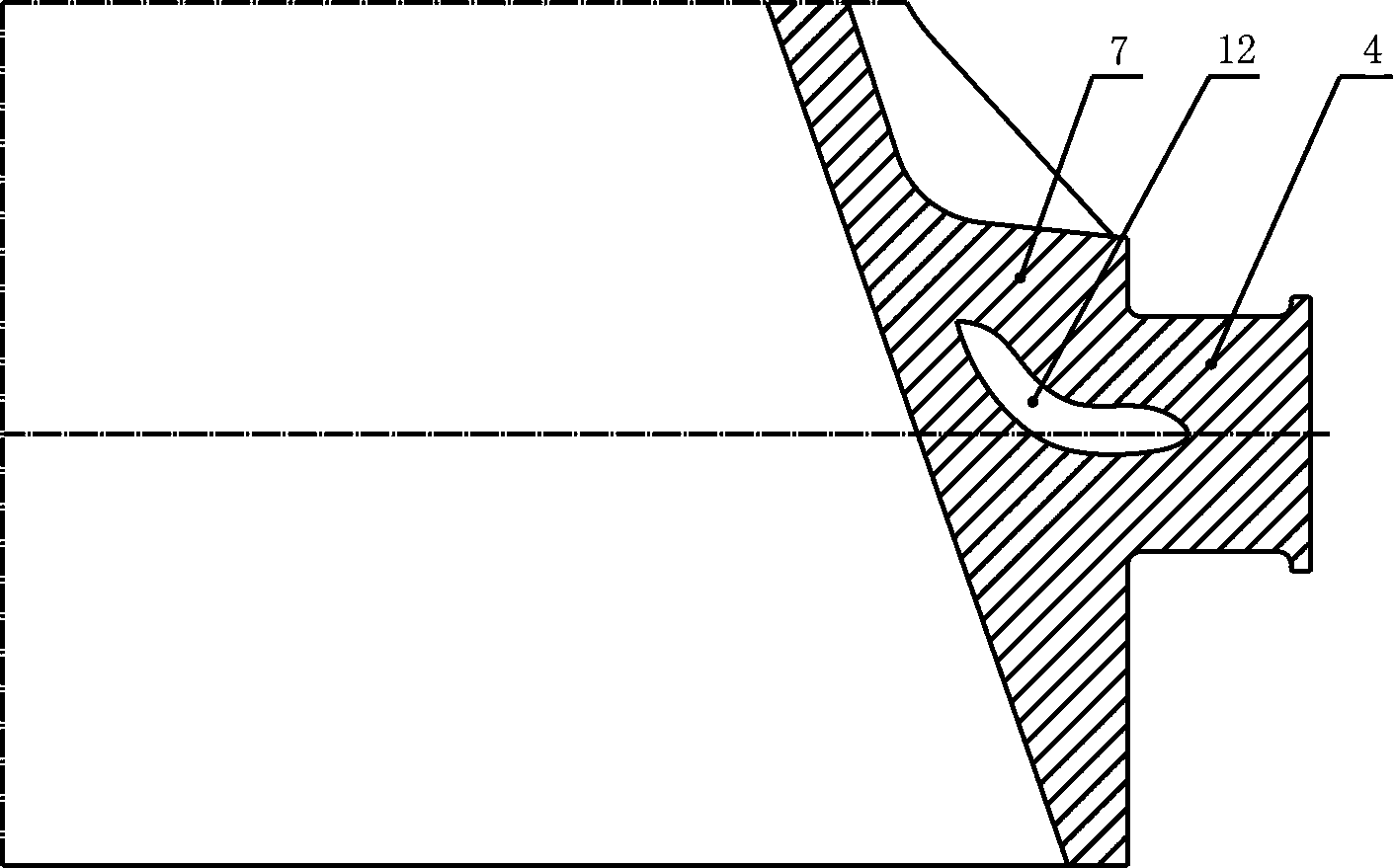

[0031] Step (1), preparation of the outer sand mold, which includes burying the processed trunnion 4 in the sand mold horizontally, and the inner end of the trunnion 4 extends into the outer sand mold cavity;

[0032] The specific steps are: use the outer sand box 5, the inner metal mold 1 and the trunnion seat wooden mold 3 sleeved on the inner end root of the trunnion 4 to prepare the outer sand mold, and the trunnion 4 and the trunnion seat wooden mold 3 are buried horizontally In the sand mold between the sand box 5 and the metal mold 1, the inner end of the trunnion 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com