Cable winding device for electric power construction

A winding device and electric power construction technology, applied in the field of electric power, can solve problems such as low winding quality and loose cables, and achieve the effect of improving winding quality and increasing winding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

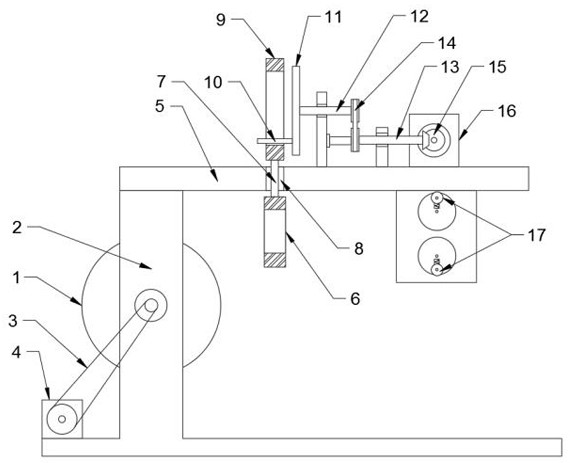

[0022] see Figure 1-5 , in an embodiment of the present invention, a cable winding device for electric power construction, including a winding reel 1 and a mounting seat 2; A winding motor 4 is connected, and the winding motor 4 is fixedly connected with the mounting base 2; the winding drum 1 is driven to rotate by the winding motor 4, and the cable is wound.

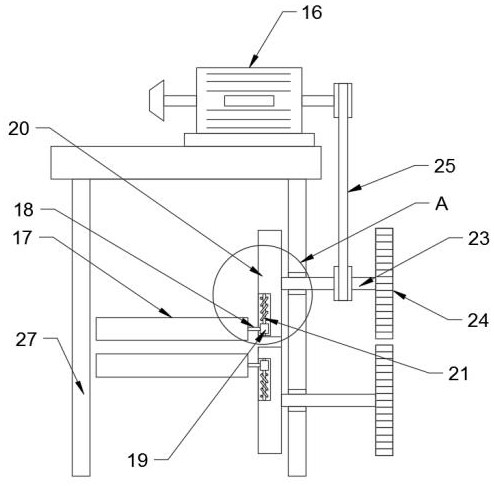

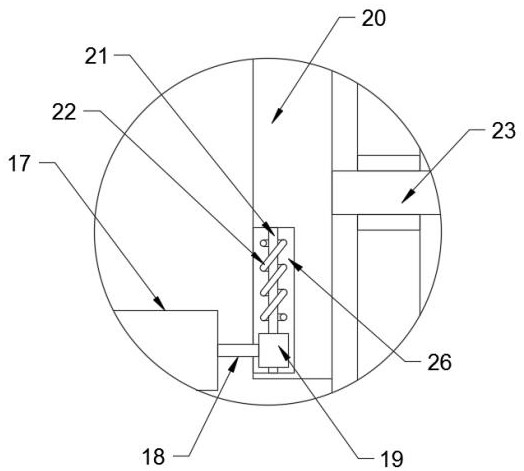

[0023] The front end of the reel 1 is provided with an elastic traction mechanism. The traction mechanism includes a set of traction rollers 17 arranged up and down oppositely. A set of traction rollers 17 are respectively connected to slide blocks 19 through rotating shafts 18, and slide blocks 19 are nested with turntables. 20, the turntable 20 is provided with a radial groove 26, the slider 19 is nested in the radial groove 26 and is slidably connected with the radial groove 26; the radial groove 26 is provided with a guide rod 21, and the guide rod 21 runs through the slider 19 and is slidably connected with the ...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that a guiding mechanism is provided between the reel 1 and the elastic traction mechanism. The guiding mechanism includes a guiding ring 6 and a longitudinal reciprocating mechanism. Sliding bar 7, top plate 5 is provided with longitudinal chute 8, and sliding bar 7 runs through longitudinal chute 8 and is slidably connected with longitudinal chute 8; The upper end of described sliding bar 7 is fixed with vertically arranged rectangular frame 9, rectangular frame 9 An eccentric column 10 is nested inside, and the eccentric column 10 is fixedly connected with an eccentric disc 11, and the eccentric disc 11 is fixedly connected with a support shaft 12, and the support shaft 12 is rotatably connected with a mounting plate, and the mounting plate is fixedly connected with the top plate 5; the support shaft 12 The transmission shaft 13 is connected with the transmission belt 14, and the transmission shaft 13 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com