Deburring machine for round billet and working method of deburring machine

A deburring machine and round billet technology, which is applied in the field of continuous casting production, can solve the problems of manual deburring and removal of burrs, and the deburring rate cannot reach 100%, and achieve the effect of low noise and guaranteed billet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the accompanying drawings.

[0029] The reciprocating hydraulic oil cylinder used in the present invention is Qiangfeng hydraulic YG003 type reciprocating hydraulic oil cylinder, and the motor is the LSD / Leisun 5IK90RGU-CF forward and reverse motor produced by Dongguan Laishidun Electromechanical Technology Co., Ltd.

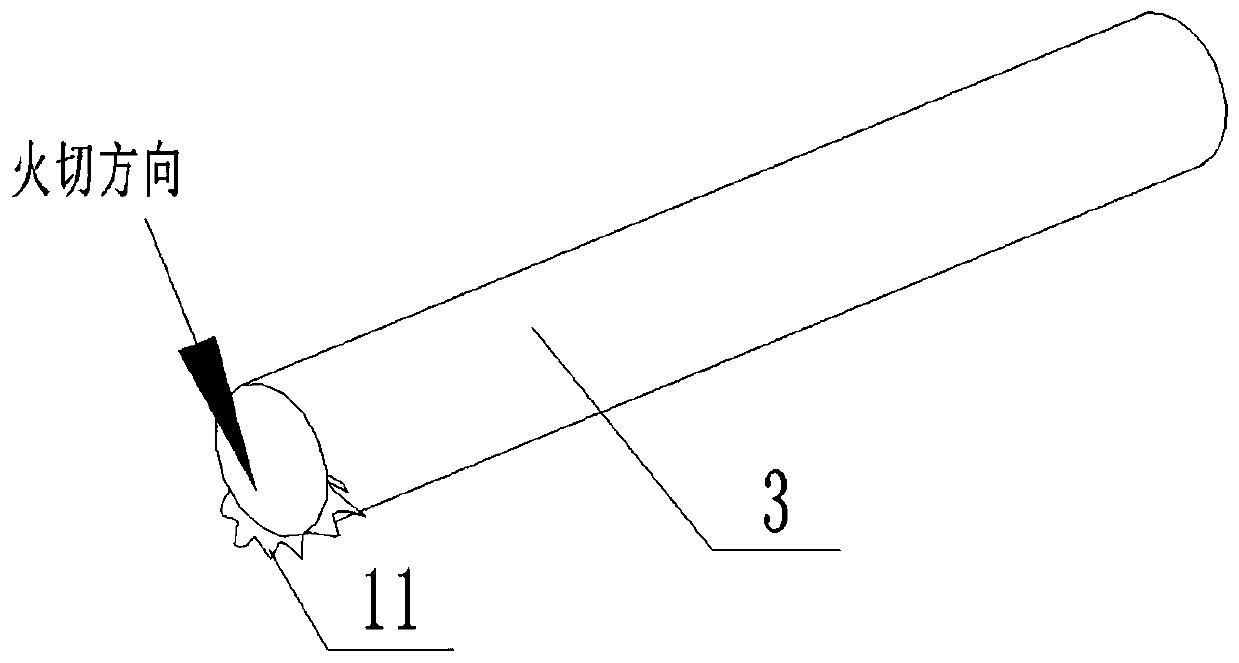

[0030] figure 1 It is a schematic diagram of the position of the burr after the round billet is cut by fire. As shown in the figure, the round billet continuous casting machine uses flame cutting to cut the round billet 3 into a fixed length. Flame cutting will inevitably form a slag burr 11 at the lower part of the cut.

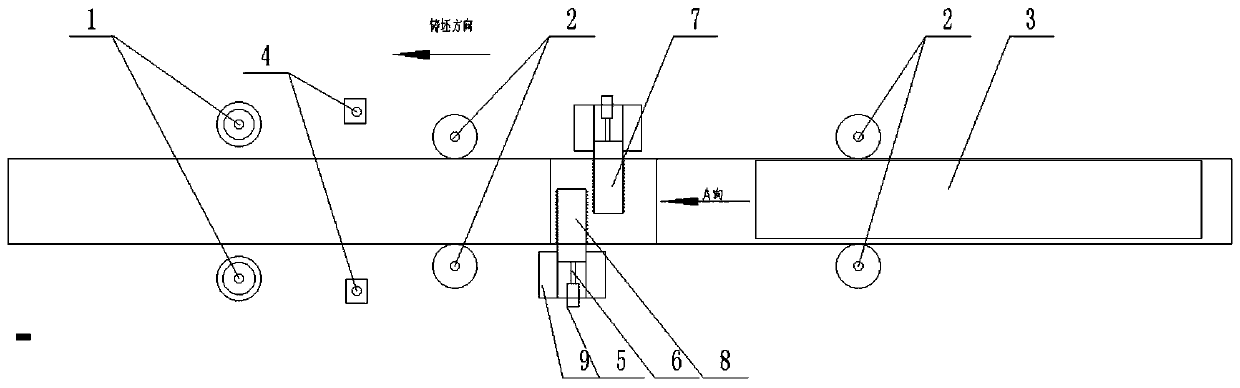

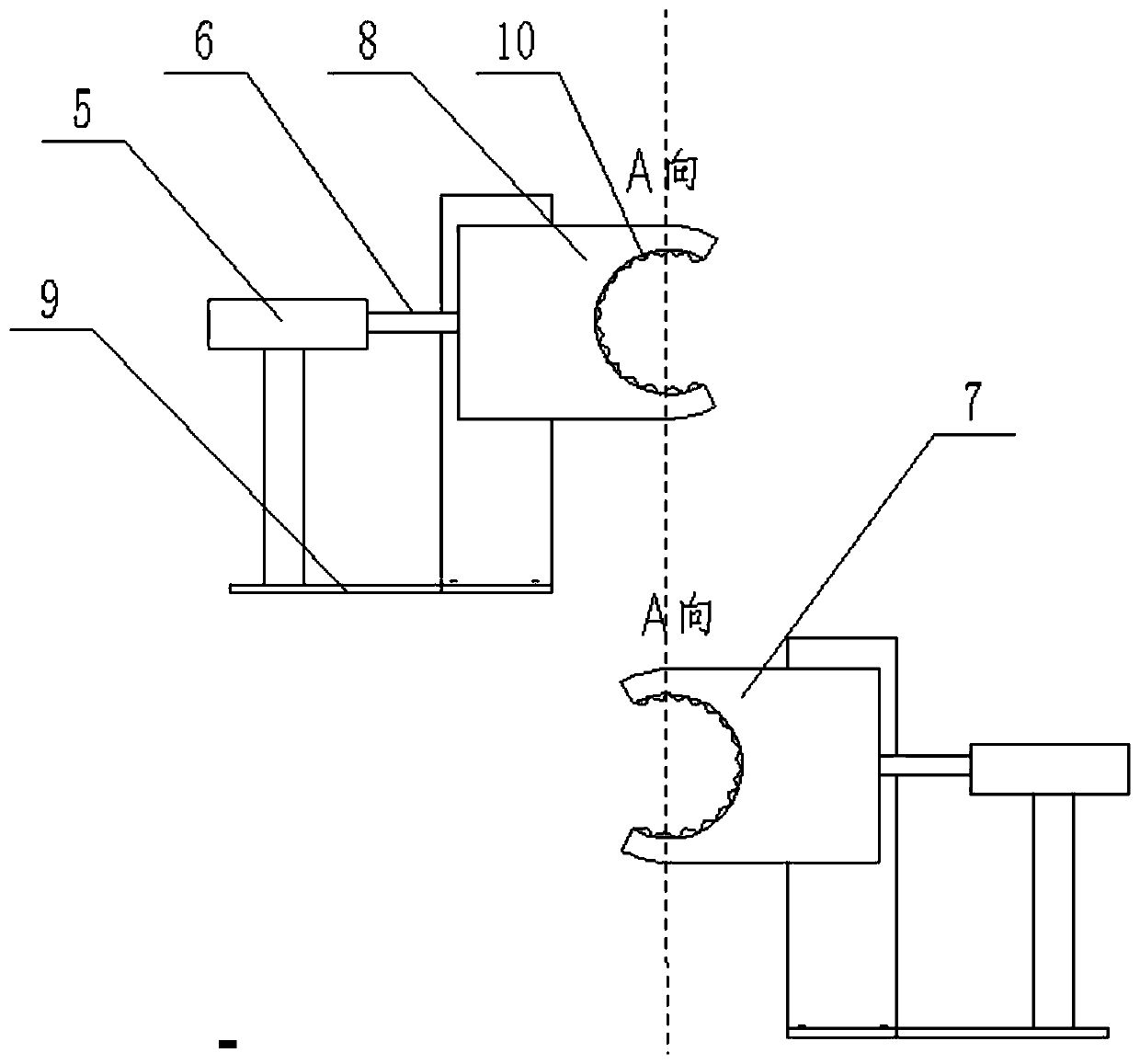

[0031] figure 2 It is a top view of the deburring machine of the present invention, image 3 It is a cross-sectional schematic diagram of the right arc-shaped toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com