Full-automatic cooking processor

A processing machine, fully automatic technology, applied in the direction of cooking utensils, household utensils, applications, etc., can solve the problems of shortening the service life of the machine, unscientific structural design, damage to the upper cover or shell, etc., to reduce housework and scope of application Wide, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

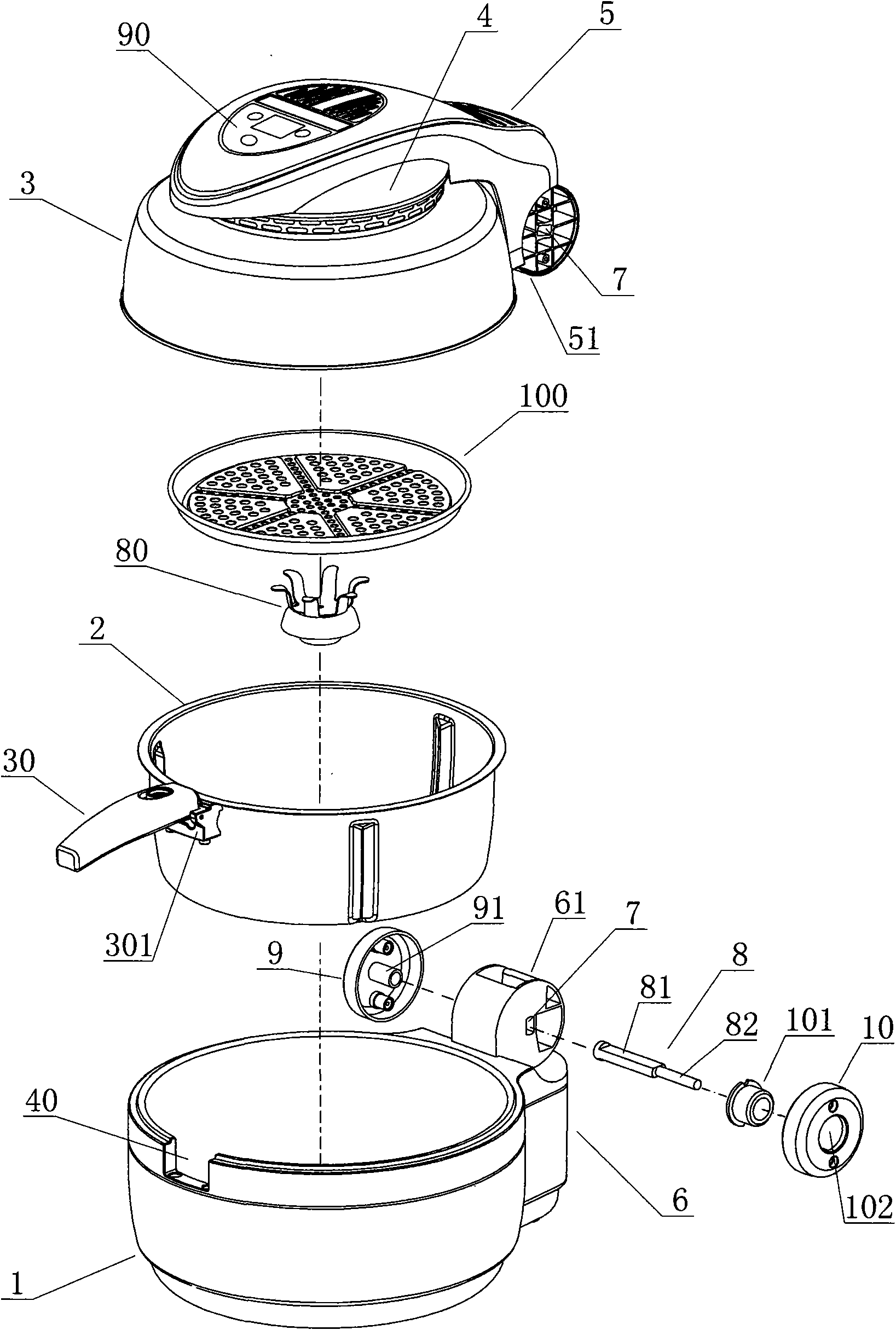

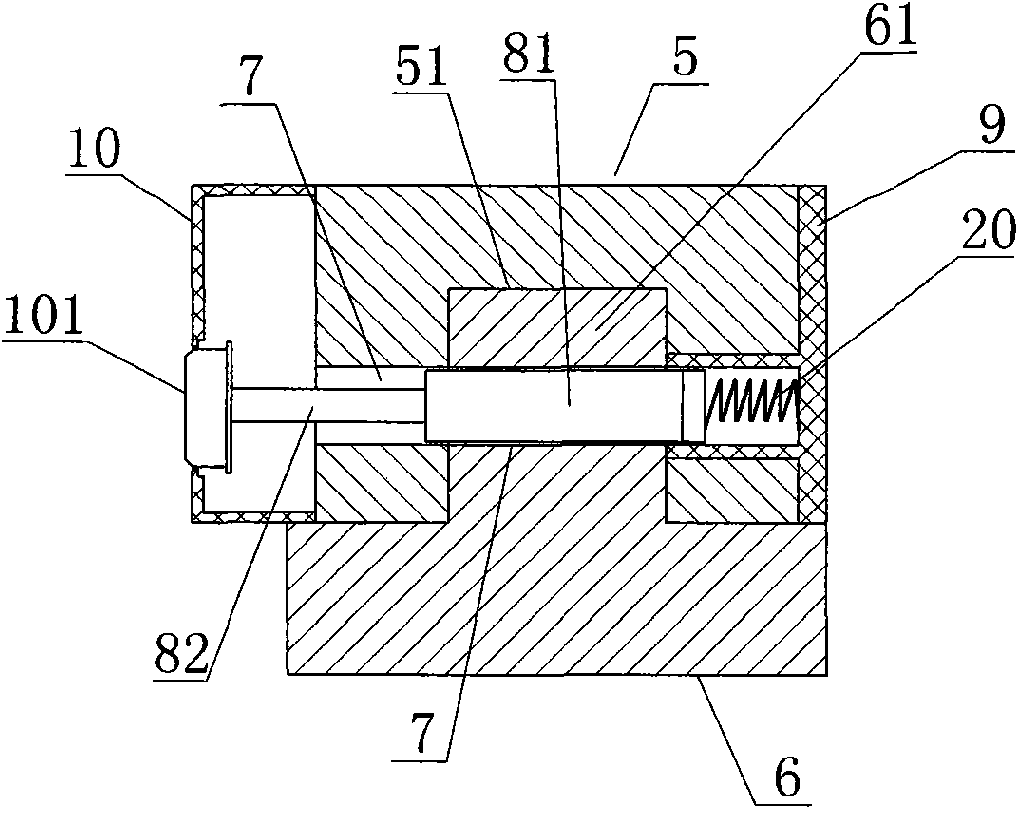

[0027] Such as figure 1 As shown, a fully automatic cooking processing machine according to the present invention includes a pot base 1, a pot body 2 and a pot cover body 3, wherein the pot cover body 3 is provided with a heating device capable of transmitting heat to the inner cavity of the pot body 2 4. The heating device 4 is generally a burner of a light-wave cooking machine. For the specific structure and working principle of the burner of a light-wave cooking machine, those skilled in the art can refer to the patent No. ZL03126826.9, which was applied by the applicant and has been published. Patent documents such as ZL200620063304.3 and ZL200720053738.X are not described in detail because they belong to the disclosed technology. During the cooking process, in order to facilitate the user to visually observe the processing process of the food in the pot body 2, the pot lid body 3 is generally made of high temperature resistant glass material. The pot body 2 is set in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com