Preparation method of mesoporous carbon/ graphene oxide compound

A technology of mesoporous carbon and graphene, which is applied in the field of preparation of mesoporous carbon/graphene oxide composites, can solve the problems of difficult to realize industrial production, cumbersome preparation process, complicated processing, etc., and achieve easy surface modification, simple process, Effect of fluffy thin-walled structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

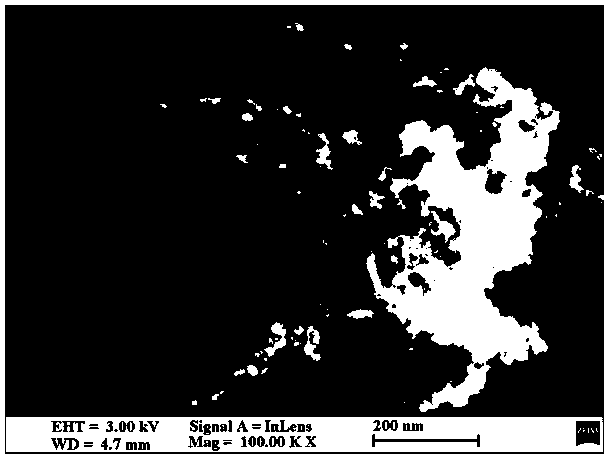

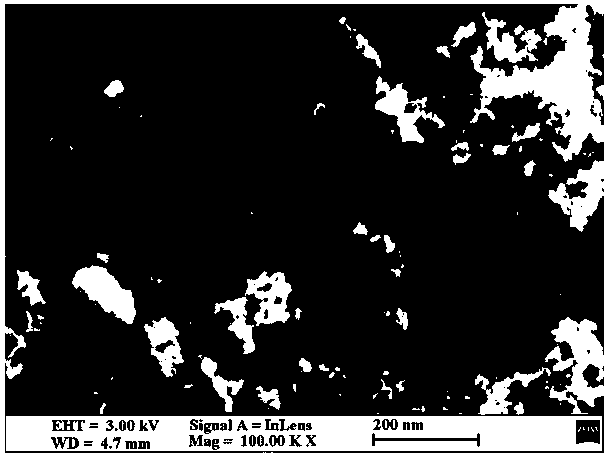

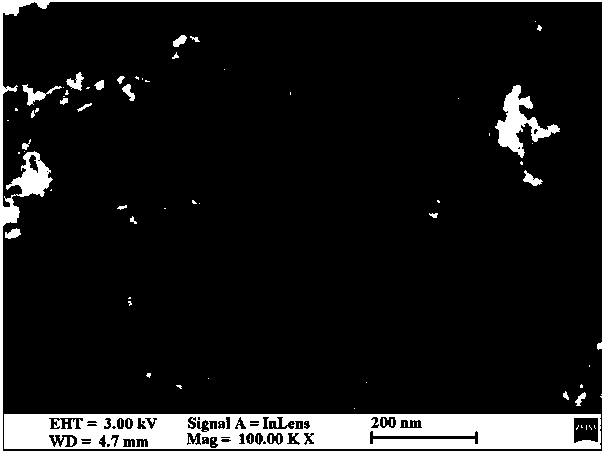

Image

Examples

Embodiment 1

[0033] A preparation method of mesoporous carbon / graphene oxide composite, comprising the steps of:

[0034] 1) Preparation of mesoporous carbon

[0035] The coal tar pitch and aluminum sulfate were weighed and mixed according to the mass ratio of 1:3, using isopropanol as the solvent, and the mass ratio of the mixture to the solvent was 1:3. The two were mixed uniformly by mechanical stirring, and nitrogen gas was introduced, the stirring temperature was 150° C., and the stirring time was 2 h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven (1.0×10 -1 Pa) Dry for 8h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, heated to 1000°C at a rate of 10°C / min, kept for 5 hours, cooled to room temperature and taken out for later use.

[0036] 2) Preparation of mesoporous carbon / graphene oxide composites

[0037] The mesoporous carbon was prepared by the improved hummers...

Embodiment 2

[0040] A preparation method of mesoporous carbon / graphene oxide composite, comprising the steps of:

[0041] 1) Preparation of mesoporous carbon

[0042]The petroleum pitch and aluminum isopropoxide were weighed and mixed according to the mass ratio of 1:1, and isopropanol was used as the solvent, and the mass ratio of the mixture to the solvent was 1:2. The two were mixed uniformly by mechanical stirring, and nitrogen gas was introduced, the stirring temperature was 110° C., and the stirring time was 1 h. After stirring evenly, the solvent was distilled off under reduced pressure, and placed in a 50°C vacuum oven (1.0×10 -1 Pa) Dry for 3h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, first heated to 600 °C at 15 °C / min, kept for 1 h, then raised to 1600 °C at 5 °C / min, kept for 2 h, cooled to room temperature and taken out for use.

[0043] 2) Preparation of mesoporous carbon / graphene oxide composites

[0044] The...

Embodiment 3

[0047] A preparation method of mesoporous carbon / graphene oxide composite, comprising the steps of:

[0048] 1) Preparation of mesoporous carbon

[0049] The natural asphalt and aluminum nitrate were weighed and mixed according to the mass ratio of 4:1, n-butanol was used as the solvent, and the mass ratio of the mixture to the solvent was 1:5. The two were mixed uniformly by mechanical stirring, and nitrogen gas was introduced, the stirring temperature was 90°C, and the stirring time was 2h. After stirring evenly, the solvent was distilled off under reduced pressure, and placed in a 90°C vacuum oven (1.0×10 -1 Pa) Dry for 5h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, heated to 800 °C at 10 °C / min, kept for 1 h, then raised to 1200 °C at 8 °C / min, kept for 2 h and kept for 4 h, cooled to room temperature and taken out for use.

[0050] 2) Preparation of mesoporous carbon / graphene oxide composites

[0051] The me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com