A kind of preparation method of magnetic clay nanocomposite material

A technology for composite nanomaterials and clay, which is applied in the field of preparation of nanocomposite materials, can solve the problems of inability to achieve adsorption efficiency and effective recycling, and achieve the effects of high yield, simple and safe process, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

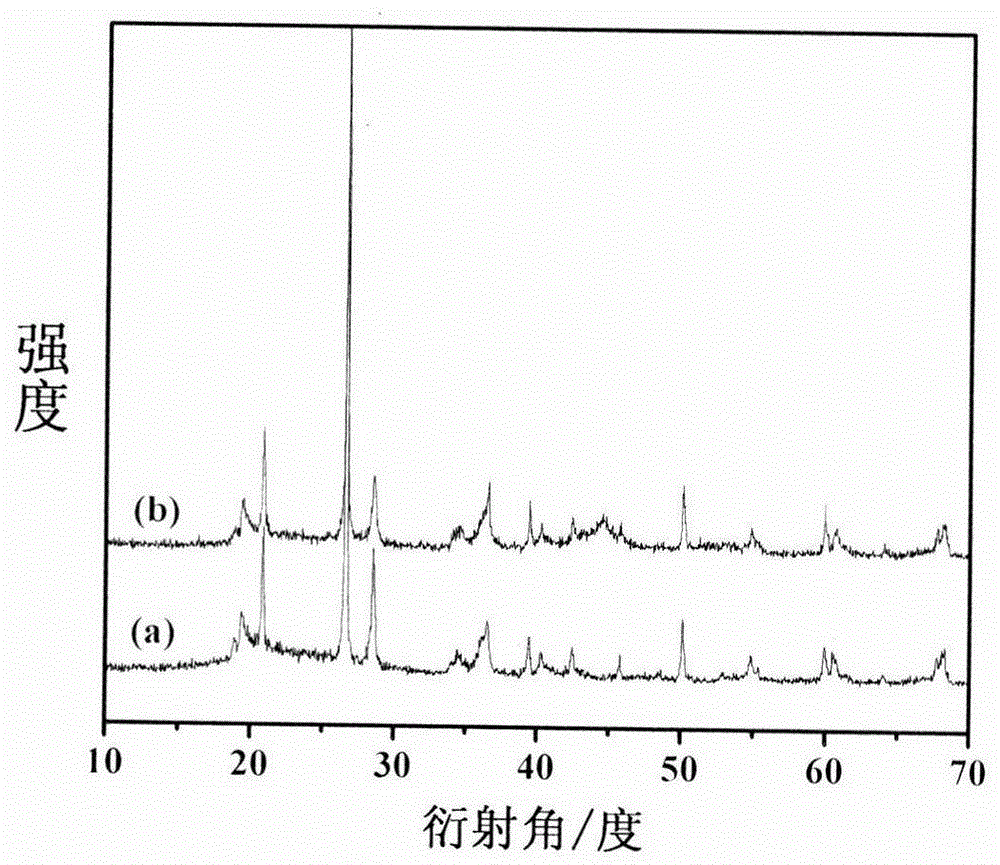

Image

Examples

Embodiment 1

[0025] 1) Weigh 10 g of attapulgite and 1 g of nickel nitrate, mix them and fully ball mill for 4 hours;

[0026] 2), putting the solid mixture obtained after ball milling in step 1) into a tube furnace and calcining for 2 hours under a nitrogen gas atmosphere at 350°C;

[0027] 3), weighing the solid mixture obtained after calcining in step 2) and sucrose by 2g and 10g respectively, and fully ball milling for 4h after mixing;

[0028] 4) Putting the solid mixture obtained by grinding in step 3) into a tube furnace and calcining for 2 hours in a nitrogen gas atmosphere at 550° C. to obtain a magnetic clay nanocomposite material.

Embodiment 2

[0030] The preparation steps are as follows:

[0031] 1) Weigh 20 g of attapulgite and 1 g of nickel nitrate, mix them and fully ball mill for 5 hours;

[0032] 2), putting the solid mixture obtained after ball milling in step 1) into a tube furnace and calcining for 3 hours under an argon gas atmosphere at 400°C;

[0033] 3) Weigh the solid mixture obtained after calcining in step 2) and maltose by 2g and 20g respectively, and fully ball mill for 5 hours after mixing;

[0034] 4) Put the solid mixture obtained by grinding in step 3) into a tube furnace and calcinate for 3 h in an argon gas] atmosphere at 600° C. to obtain a magnetic clay nanocomposite material.

Embodiment 3

[0036] 1) Weigh 15g of sepiolite and 1g of nickel nitrate and mix them and fully ball mill for 4h;

[0037] 2), putting the solid mixture obtained after ball milling in step 1) into a tube furnace and calcining for 4 hours under a nitrogen gas atmosphere at 450°C;

[0038] 3), weighing the solid mixture obtained after calcining in step 2) and glucose by 2 g and 30 g, respectively, and fully ball milling for 6 hours after mixing;

[0039] 4) Putting the solid mixture obtained by grinding in step 3) into a tube furnace and calcining for 4 hours in a nitrogen gas atmosphere at 650° C. to obtain a magnetic clay nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com