A kind of preparation method of water-soluble concrete silane emulsion waterproofing agent

A technology of silane emulsion and concrete, which is applied in the field of preparation of concrete silane emulsion waterproofing agent, which can solve the problems of difficulty in preparation of silane emulsion and poor stability, and achieve the effects of excellent fluidity, improved waterproof effect, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

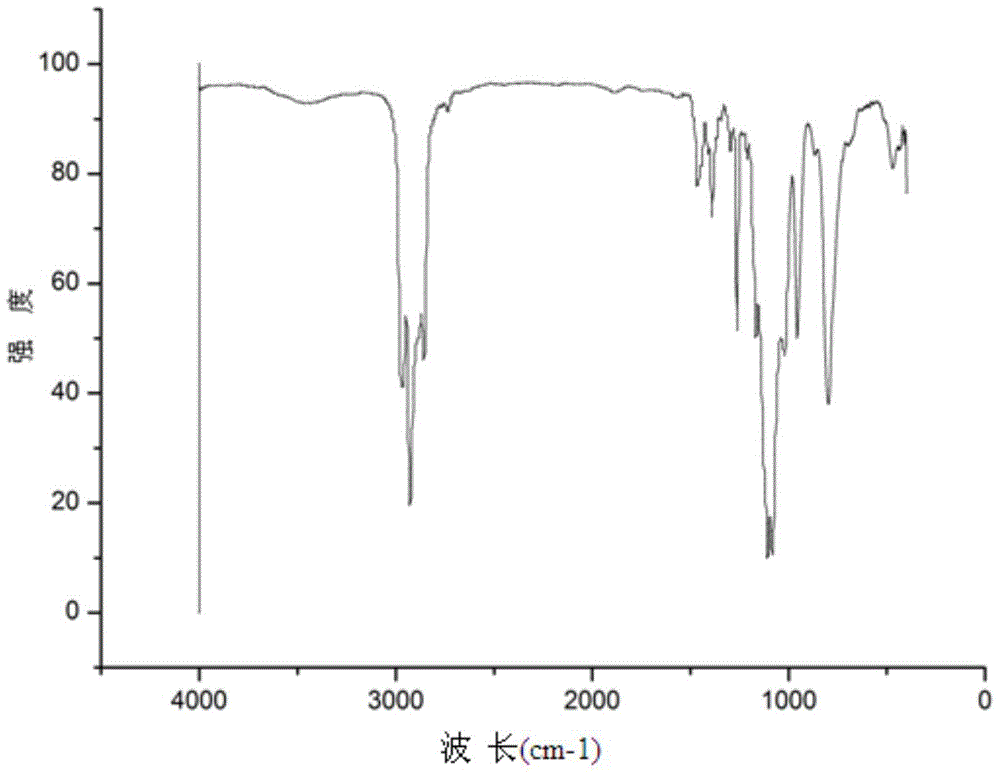

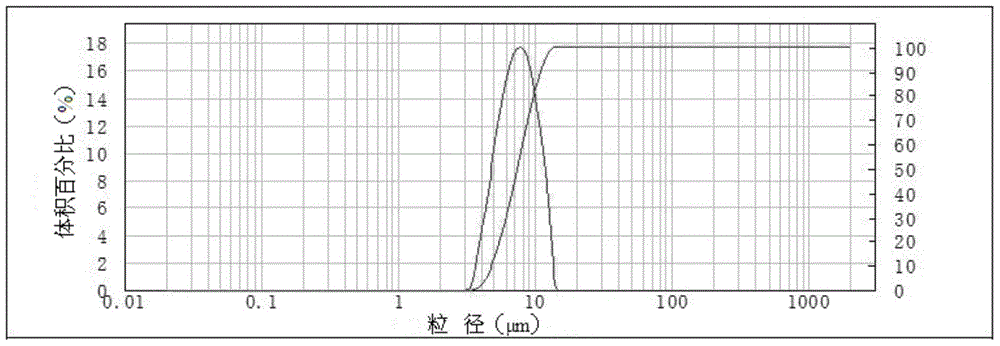

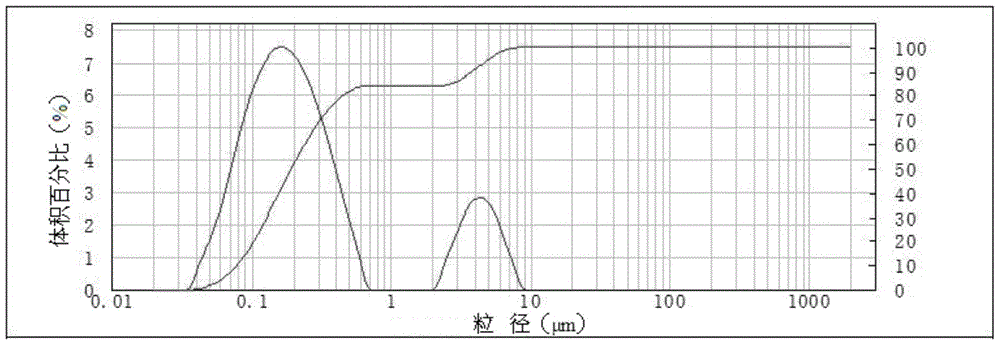

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the preparation method of a kind of water-soluble concrete silane emulsion waterproofing agent of the present embodiment is carried out according to the following steps:

[0025] 1. Preparation of polymer base material: Add compound emulsifier to distilled water, turn on the magnetic stirrer at 400-600rpm, and heat to 60-80°C at the same time, until the compound emulsifier is completely dissolved in water and becomes a transparent solution, then adjust the temperature To 90 ° C, add amino silicone oil, then add 5 drops of triethylamine as a catalyst, then control the temperature of the system at 60 ~ 80 ° C, use a peristaltic pump to add the reaction monomer n-octyl triethoxy at a rate of one drop per second Silane and reflux, then add acrylic synthetic resin emulsion, react for 6 to 8 hours, cool to obtain a white emulsion; wherein, the mass ratio of the distilled water to the composite emulsifier is 5 to 10:1; the composite emulsifier consists ...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the distilled water and the compound emulsifier described in step 1 is 10:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the composite emulsifier described in step one is made of 18 amine polyoxyethylene ether, iso-13 alcohol polyoxyethylene ether and dodecylsulfonic acid Sodium is composed in a mass ratio of 1:1:2. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com