Preparation method of manganese difluoride and graphite nanocomposite for cathode material of lithium ion battery

A technology of lithium-ion batteries and nanocomposites, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of simple and safe process, high yield and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

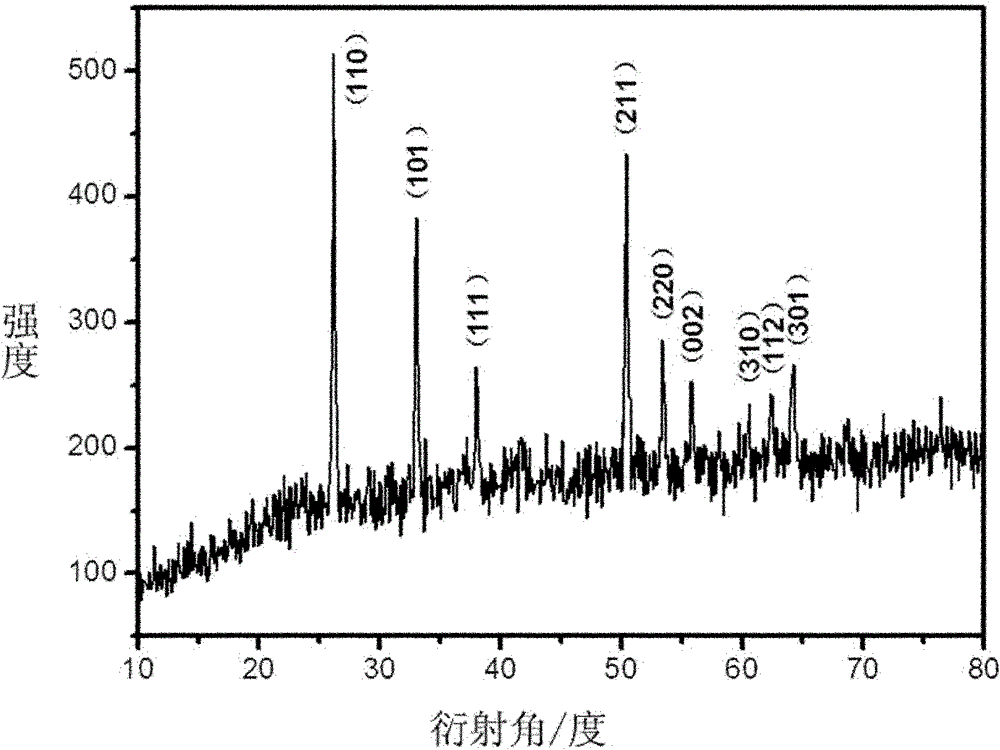

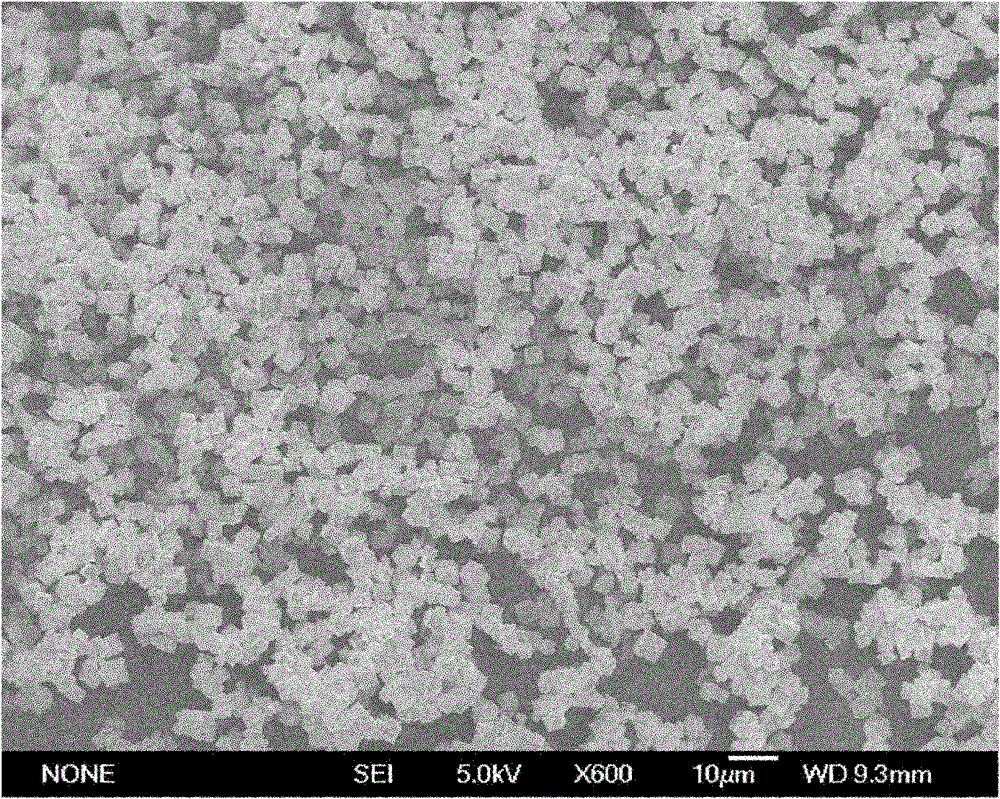

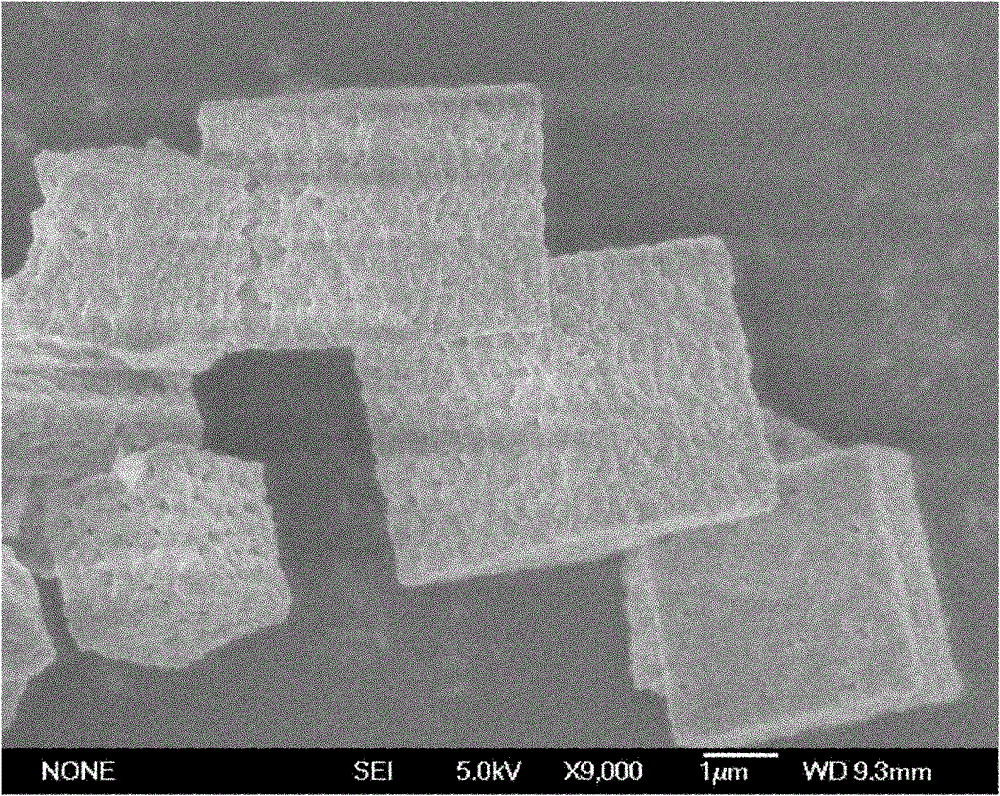

Embodiment 1

[0022] The 50% manganese nitrate solution of 1.7mL is dissolved in 150mL dehydrated alcohol and is made into solution, in this solution, add 3.0g Polyethylene Glycol 2000 as tensio-active agent, stirring and dissolving forms colorless solution, is solution (1 ); Dissolve 2.8g of ammonium fluoride in 150mL of distilled water to form a colorless solution, which is solution (2); gradually add solution (2) dropwise to solution (1) while stirring to form a white precipitate ; The obtained white precipitate was centrifugally washed, dried in a vacuum oven at 80°C to obtain a white powder; the obtained white powder was calcined in a tube furnace, and burned at 420°C under the condition of feeding argon to isolate the air. After 2 hours, manganese difluoride powder was obtained; the obtained manganese difluoride powder was mixed with graphite in a mass ratio of 1:1, and mechanically ball milled for 6 hours under the condition of feeding argon to obtain the negative electrode of lithium...

Embodiment 2

[0025] The 50% manganese nitrate solution of 4.4mL is dissolved in 150mL dehydrated alcohol and is made into solution, in this solution, add 3.0g Polyethylene Glycol 2000 as tensio-active agent, stirring and dissolving forms colorless solution, is solution (1 ); Dissolve 5.6g of ammonium fluoride in 150mL of distilled water to form a colorless solution, which is solution (2); gradually add solution (2) dropwise to solution (1) under vigorous stirring to form a white Precipitation; the obtained white precipitate was centrifuged and washed, and dried in a vacuum oven at 80°C to obtain a white powder; the obtained white powder was calcined in a tube furnace at 420°C under the condition of feeding argon to isolate the air Burn for 2 hours to obtain manganese difluoride powder; mix the obtained manganese difluoride powder with graphite in a mass ratio of 1:1, and mechanically ball mill for 4 hours under the condition of feeding argon to obtain a lithium-ion battery The negative ele...

Embodiment 3

[0029] The 50% manganese nitrate solution of 3.5mL is dissolved in 150mL dehydrated alcohol and is made into solution, in this solution, add 3.0g Polyethylene Glycol 2000 as tensio-active agent, stirring and dissolving forms colorless solution, is solution (1 ); Dissolve 3.3g of ammonium fluoride in 150mL of distilled water to form a colorless solution, which is solution (2); gradually add solution (2) dropwise to solution (1) under vigorous stirring to form White precipitate; the obtained white precipitate was centrifuged and washed, and dried in a vacuum oven at 80°C to obtain a white powder; the obtained white powder was calcined in a tube furnace, and in the case of feeding argon to isolate the air, 420 Burn at ℃ for 4 hours to obtain manganese difluoride powder; mix the obtained manganese difluoride powder with graphite at a mass ratio of 1:1, and mechanically ball mill for 5 hours under the condition of feeding argon gas to obtain lithium ion A nanocomposite of manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com