A kind of preparation method of monodisperse cobalt-nickel composite mof-74

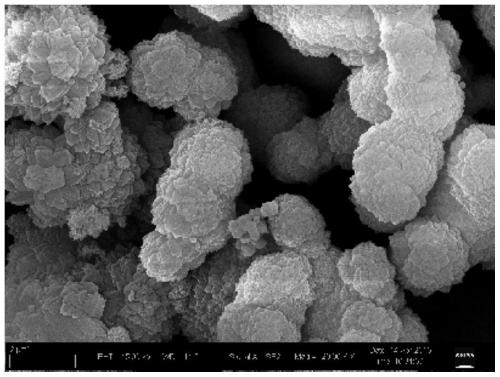

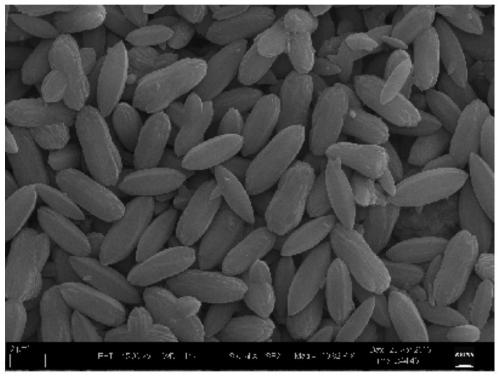

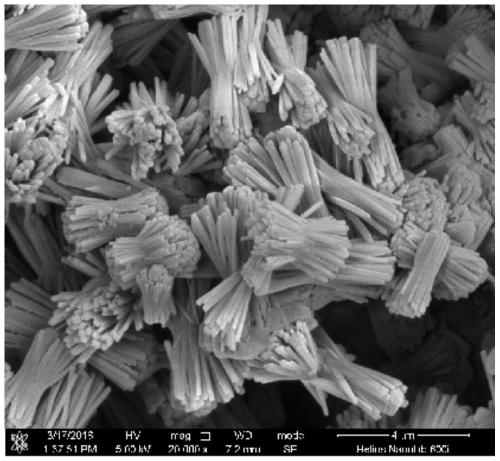

A MOF-74, monodisperse technology, applied in the direction of cobalt organic compounds, chemical instruments and methods, compounds containing elements of group 8/9/10/18 of the periodic table, etc., can solve the problem of poor stability of MOF and uneven MOF particles and other problems, to achieve the effects of narrow size dispersion, high atom utilization, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: This embodiment is a method for preparing monodisperse cobalt-nickel composite MOF-74, which is completed according to the following steps:

[0031] 1. Preparation of MOF-74Ni:

[0032] Dissolve 2,5-dihydroxyterephthalic acid and nickel nitrate hexahydrate into solvent I to obtain a mixed solution of 2,5-dihydroxyterephthalic acid and nickel nitrate hexahydrate; Acetic acid and polyvinylpyrrolidone aqueous solution with a mass fraction of 1% to 30% are added to the mixed solution of phthalic acid and nickel nitrate hexahydrate to obtain a reaction solution; the reaction solution is reacted at a temperature of 100°C to 180°C for 12h to 72h, Obtain MOF-74Ni;

[0033] The concentration of 2,5-dihydroxyterephthalic acid in the mixed solution of 2,5-dihydroxyterephthalic acid and nickel nitrate hexahydrate described in step 1 is 5mmol / L~30mmol / L;

[0034] The concentration of nickel nitrate hexahydrate in the mixed solution of 2,5-dihydroxyterephthalic acid a...

specific Embodiment approach 2

[0050] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the solvent I described in step 1 is one of acetone, tetrahydrofuran, methanol, N,N-dimethylacetamide, absolute ethanol and water or a mixture of several of them. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0051]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solvent I described in step 1 is acetone, N,N-dimethylacetamide and absolute ethanol at a ratio of 1:1: The mixed solution mixed with a volume ratio of 1, the mixed solution mixed with water, N,N-dimethylacetamide and absolute ethanol at a volume ratio of 1:2:1 or tetrahydrofuran, N,N-dimethylacetamide and A mixture of absolute ethanol at a volume ratio of 1:2:1. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com