Method for solidifying powder paint on lumber component surface

A powder coating and surface curing technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of inability to be absorbed by powder coating, unsuitable for baking paint process, and inability to apply baking paint process, etc. The effect of not easy to fade, long service life and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

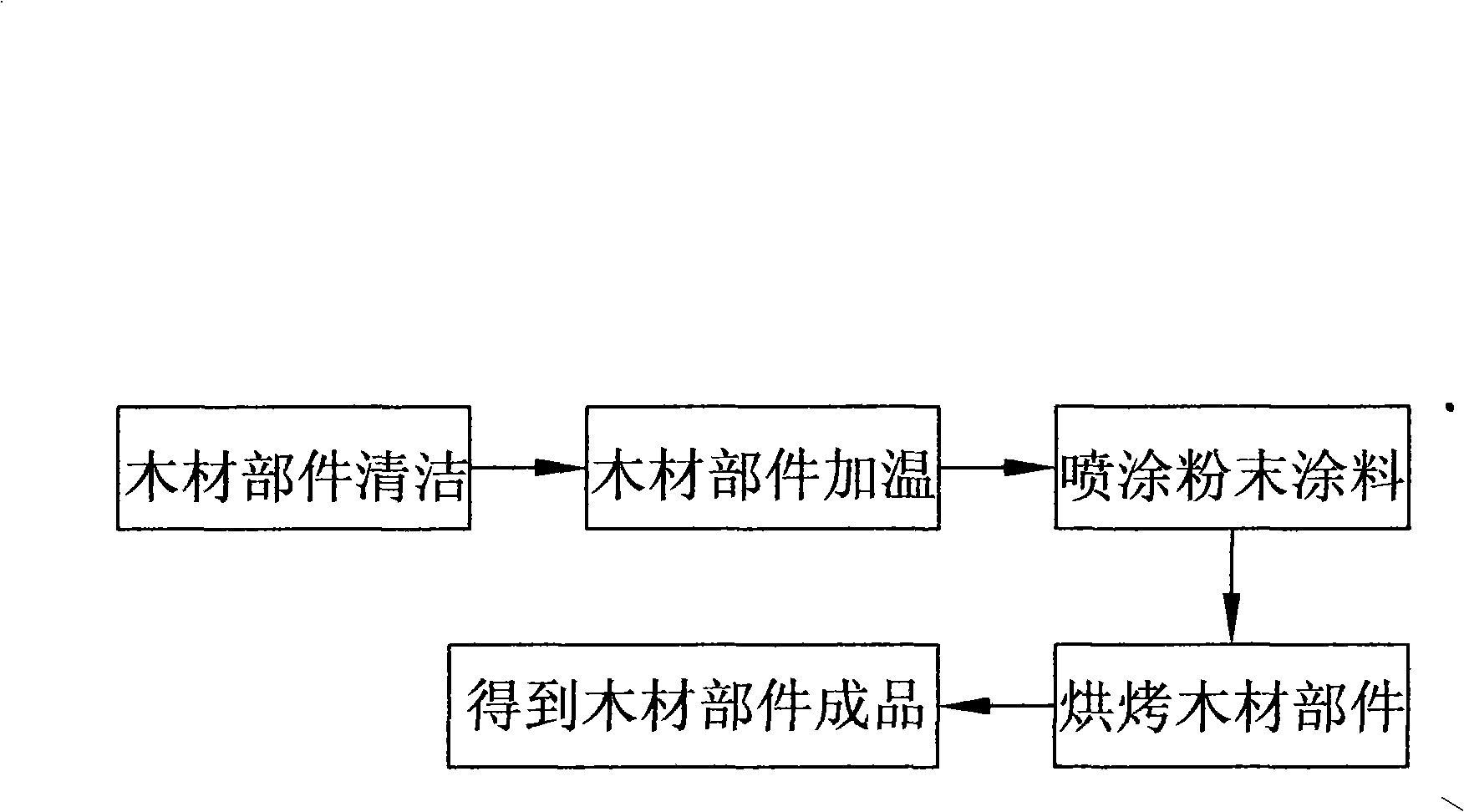

[0016] like figure 1 Shown, a kind of method of solidifying powder coating on the wood part surface of the present invention, it comprises following method step:

[0017] First, the pre-prepared wood parts are blown and cleaned to remove the residual dust on the surface of the wood parts. As we all know, wood generally cannot be cleaned with water. Washing with water will make the wood parts absorb a lot of water, making it difficult to dry. It not only greatly affects the quality of the subsequent baking varnish process, but also affects the future service life of the wood parts and the quality of the wood parts application. Therefore, the present invention skillfully uses blowing equipment (such as a high-pressure air gun) that can blow out a certain wind speed and pressure to carry out wind blowing cleaning to each wood part, which can not only effectively clean the remaining dust on the surface of the wood part, but also prevent Moisture is attached to the wood parts to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com