Efficient cyclone-type powder selecting machine

A cyclone type, powder separator technology, applied in the direction of solid separation, separation of solids from solids with air flow, chemical instruments and methods, etc., can solve the problems of unstable screening range, low sorting efficiency, single structure, etc. , to achieve the effect of stable screening range, high sorting efficiency and excellent structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

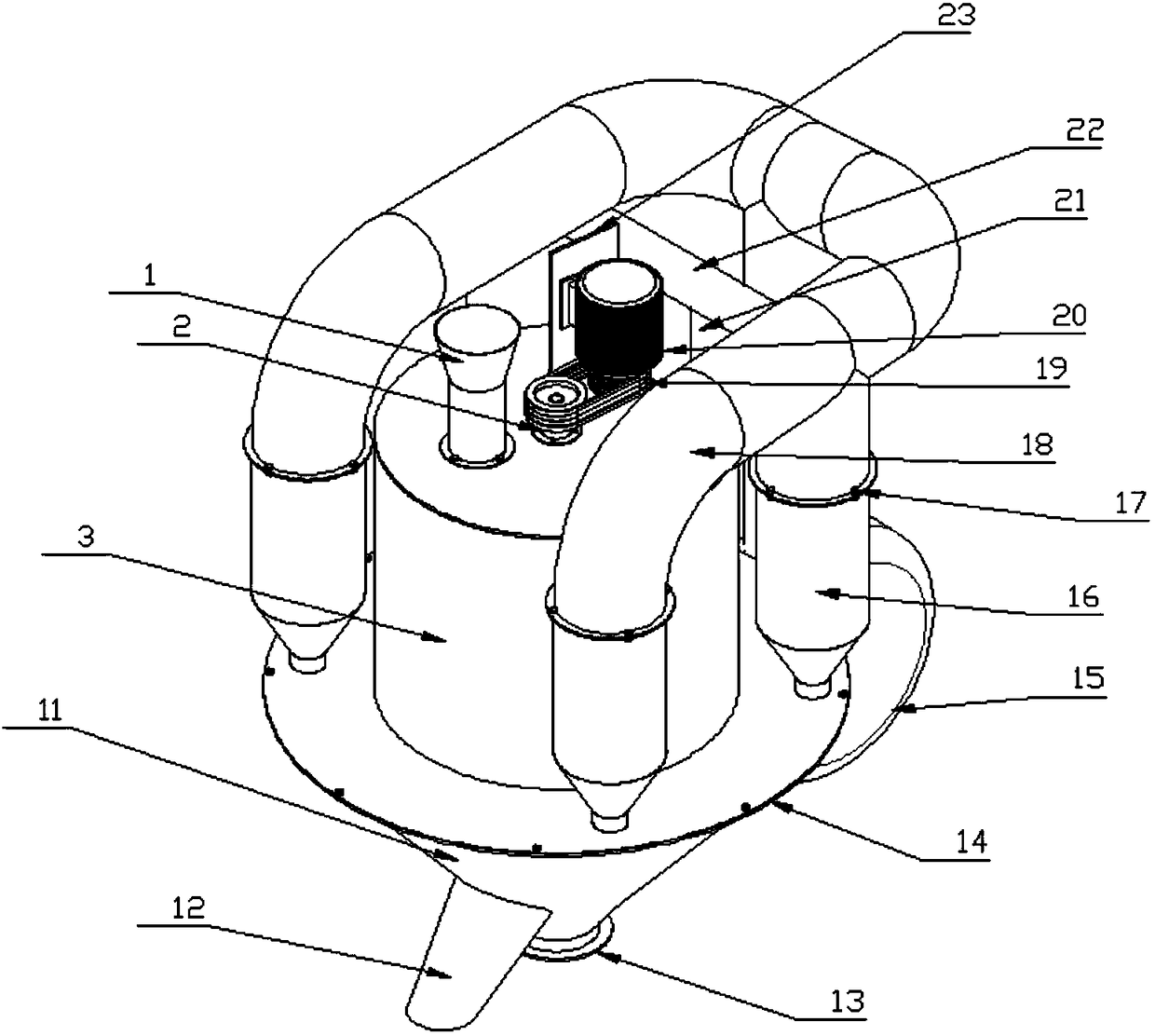

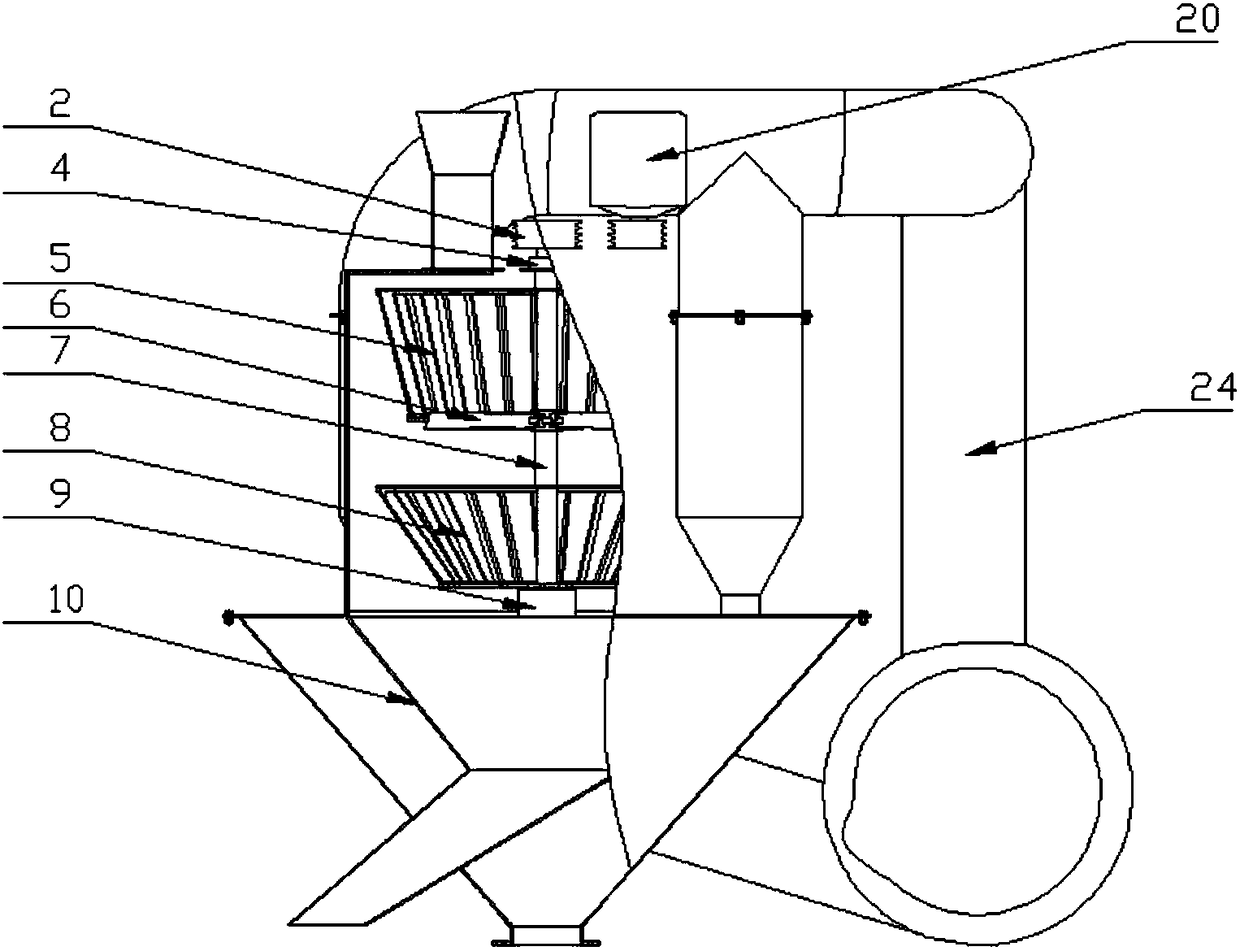

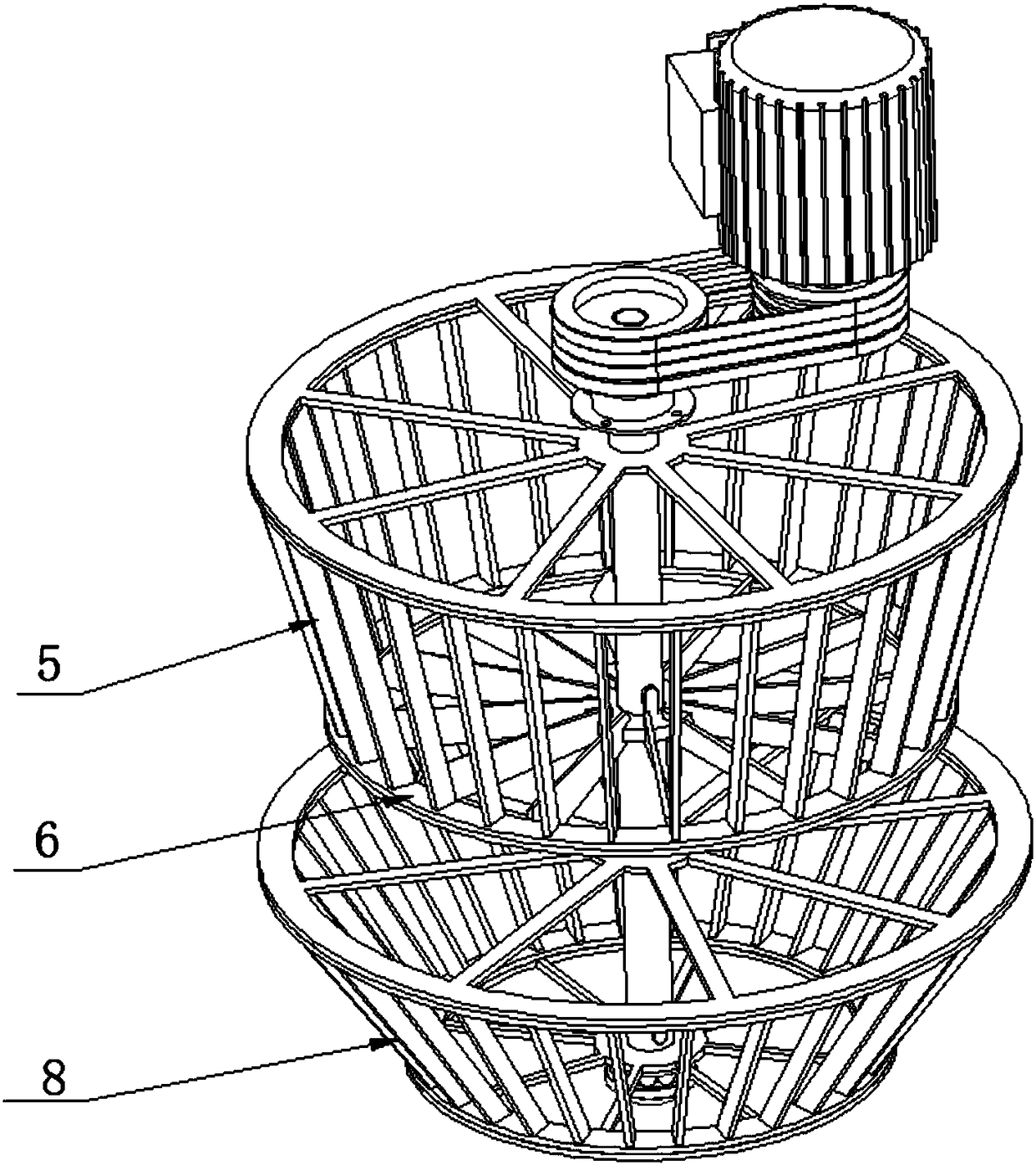

[0030] A high-efficiency cyclone-type powder separator, including: feed inlet 1, driven pulley 2, powder selection box 3, bearing cover 4, upper cage rotor 5, spreading disc 6, rotating shaft 7, lower cage rotor 8. Rotary shaft support 9, coarse material guide pipe 10, fine powder collection cylinder 11, coarse material discharge port 12, fine powder discharge port 13, collection cylinder cover 14, blower 15, fine powder settling cylinder 16, separation chute Pipe bolt 17, fine powder guide pipe 18, driving pulley 19, motor 20, screening pipe 21, shunt pipe 22, motor bracket 23 and fixed pillar 24; feed port 1 is arranged on the powder selection box 3 through flange connection The left side of the upper end and the right side of the upper end of the powder selection box 3 are provided with a motor bracket 23 connected by welding; the front side of the motor bracket 23 is provided with a motor 20 connected by bolts, and the lower side of the motor 20 is provided with a The driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com