A complete set of high concentration flotation machine

A complete set of equipment and flotation machine technology, applied in flotation, solid separation, etc., can solve the problems of flotation machine configuration not reflected, no stirring system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

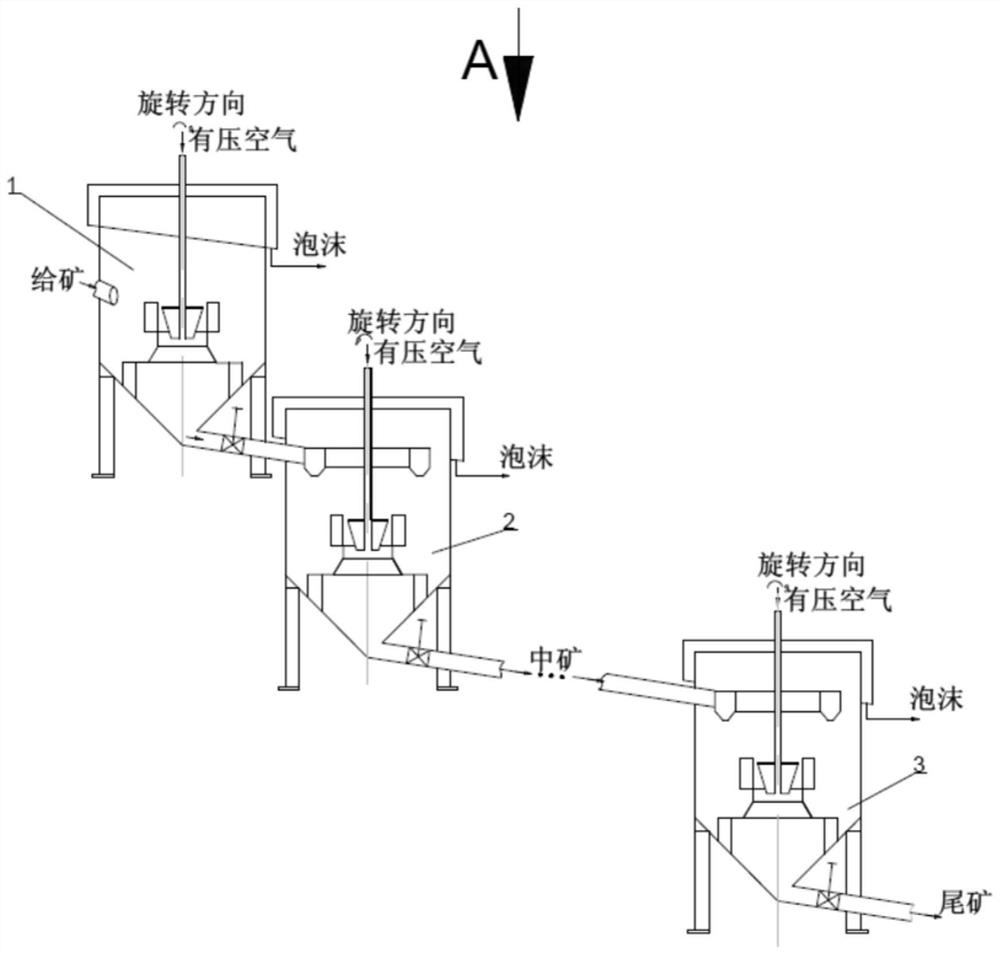

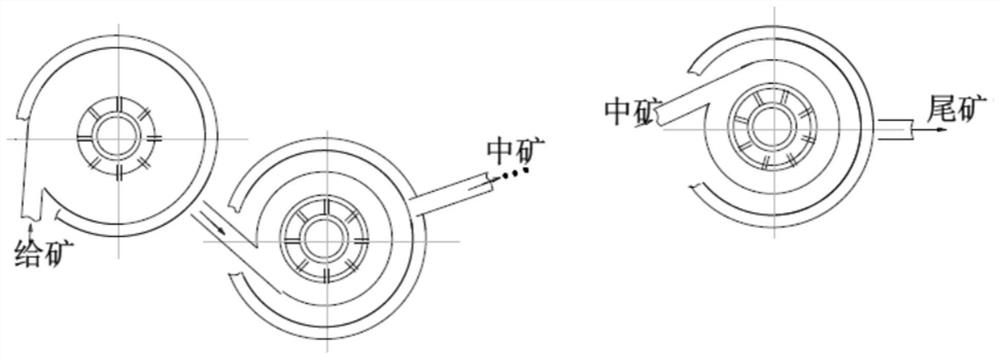

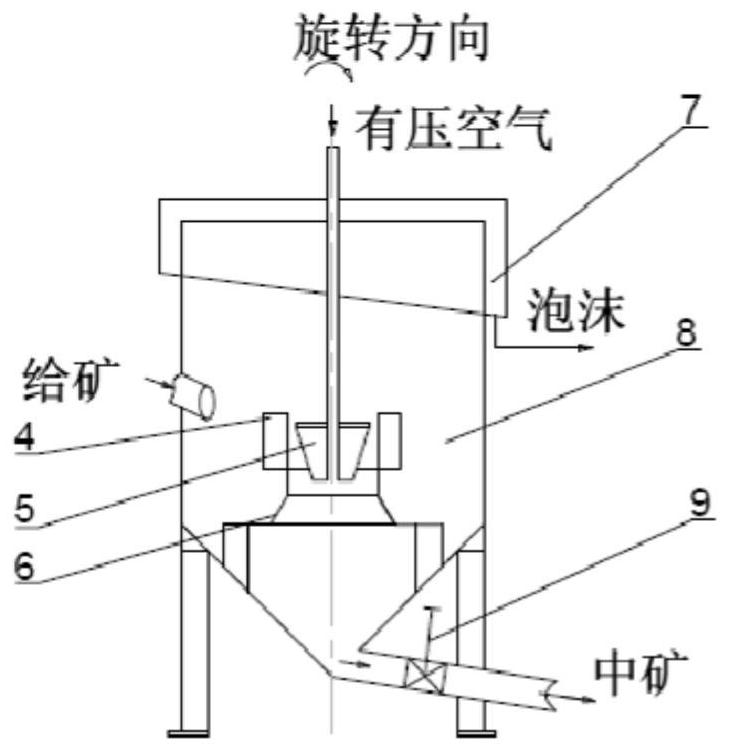

[0042] Such as figure 1 , figure 2 As shown, it includes an ore feeding flotation machine 1, a middle selection flotation machine 2 and a tailing flotation machine 3. Generally, it consists of 1 feeding flotation machine 1, 2-5 flotation machines 2 for middle selection (determined by the flotation time), and 1 tailing flotation machine 3. The fresh ore pulp is generally fed to the side of the inner impeller of the flotation machine along the tangential direction of the ore feeding flotation machine 1, and the bottom flow of the flotation machine for the ore feeding is fed into the slurry distributor of the middle selection flotation machine 2 as the middle ore tangentially. From the bottom of the previous flotation machine, it is tangentially fed into the next intermediate flotation machine, and multiple intermediate flotation machines are arranged tangentially in a staggered direction; the bottom flow of the last intermediate flotation machine is tangentially fed into the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com