Suspension assembly for laundry machine

A technology for suspension devices and washing machines, applied to washing devices, other washing machines, washing machines with containers, etc., can solve the problems of not having, reducing vibration, and not being able to provide optimal suspension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

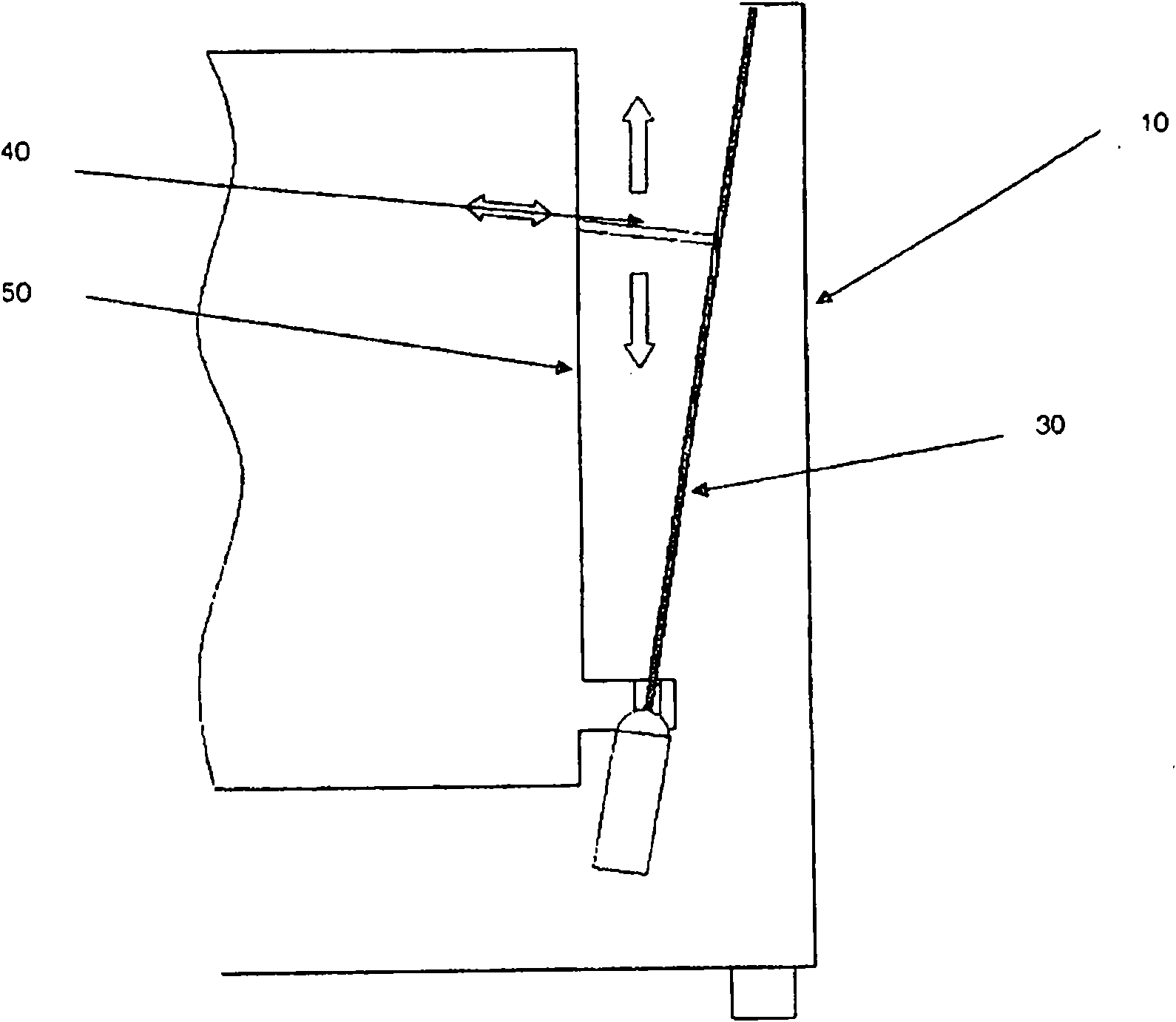

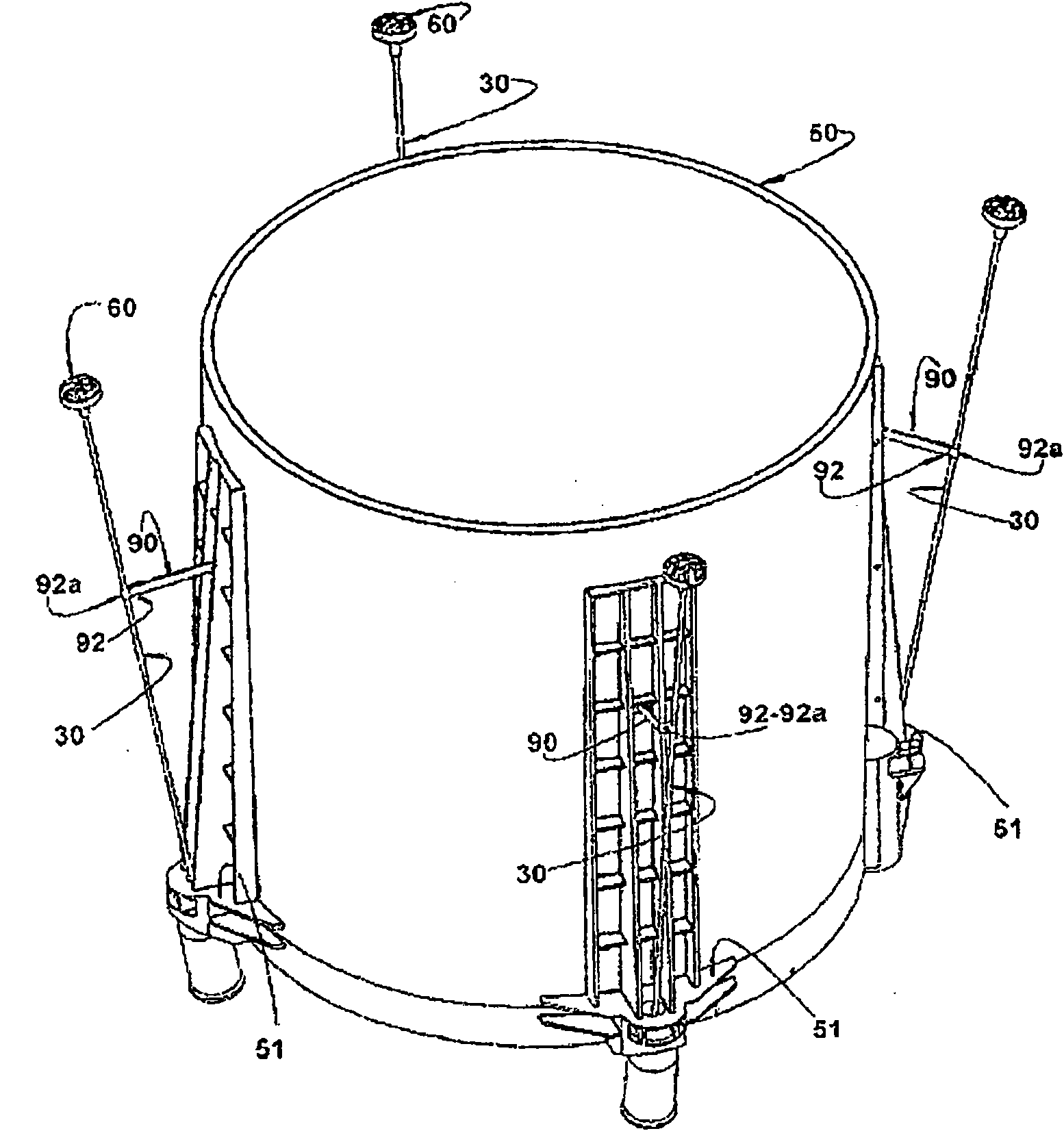

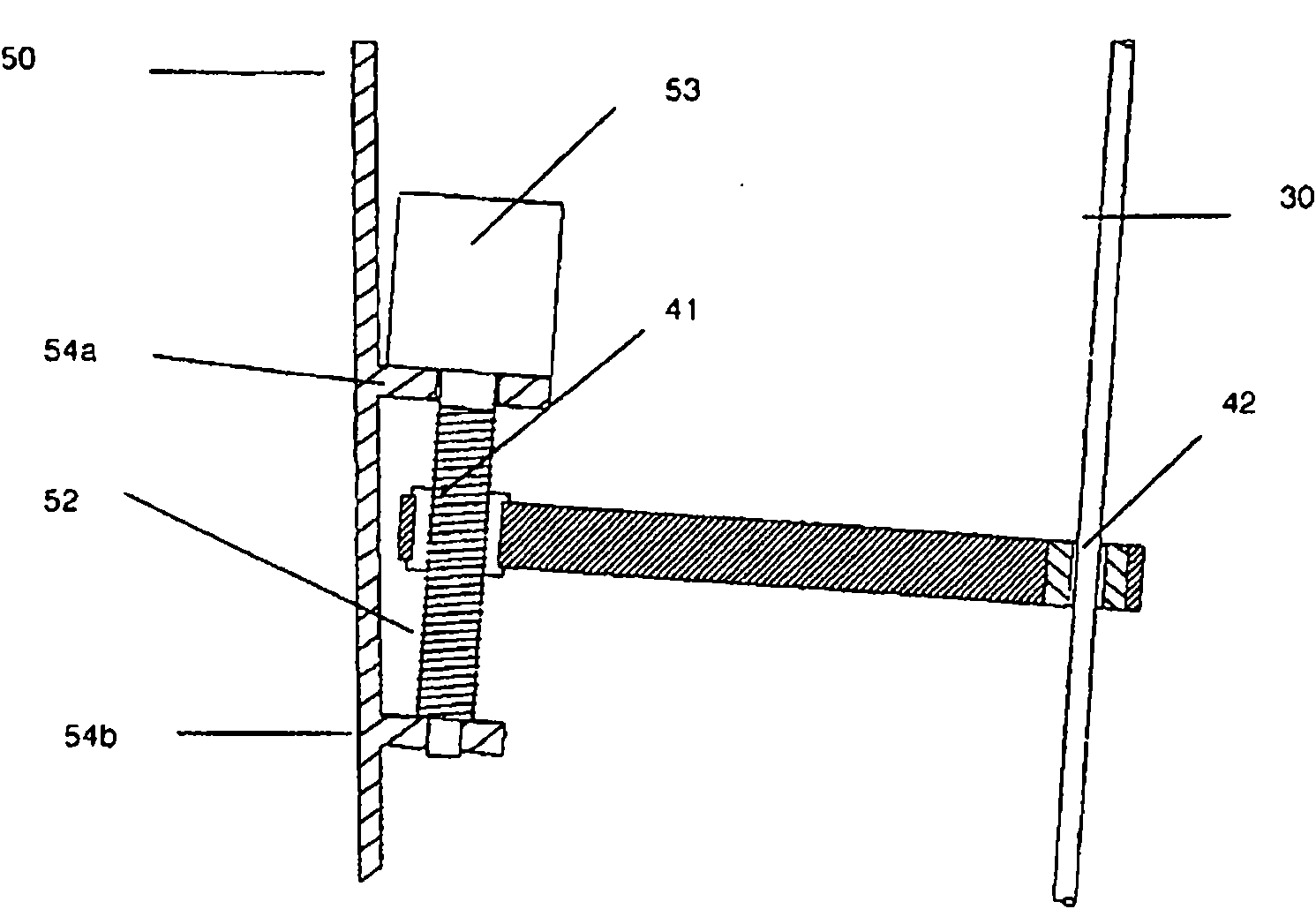

[0022] Hereinafter, the present application will be described in more detail based on working examples shown in the drawings. Although the following description exemplifies a suspension device of a vertical-axis washing machine with a top-loading door, those skilled in the art can imagine that the present invention can be applied to other types of washing machines, such as a horizontal-axis washing machine with a front-loading door.

[0023] figure 1 A schematic sectional view of a washing machine comprising the suspension device of the present invention is shown. The washing machine comprises a structural casing 10, the construction of which is well known in the art. A tub 50 containing washing liquid is provided inside the housing. Said structural housing 10 and bucket 50 are widely known in the prior art, wherein, for the purposes of illustration and description, Brazilian patent application PI 0705172-7 is used herein as an example structure.

[0024] In this structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com