Aluminum alloy surface phosphatizing fluid and phosphatizing method

A technology of aluminum alloy surface and phosphating treatment, applied in the direction of metal material coating process, etc., to achieve the effect of easy management and control, good corrosion resistance, and fast film forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, the formula that adopts phosphating solution is (containing per liter): Zn 2+ 5.0g, PO 4 3- 20g, F - 1.5g, Ni 2+ 0.7g, 1.0g ammonium molybdate, 0.6g guanidine nitrate, 0.4g salicylic acid; the phosphating treatment solution was prepared with deionized water, and the pH value of the phosphating treatment solution was adjusted to 3.5-3.7 with 30wt.% NaOH solution.

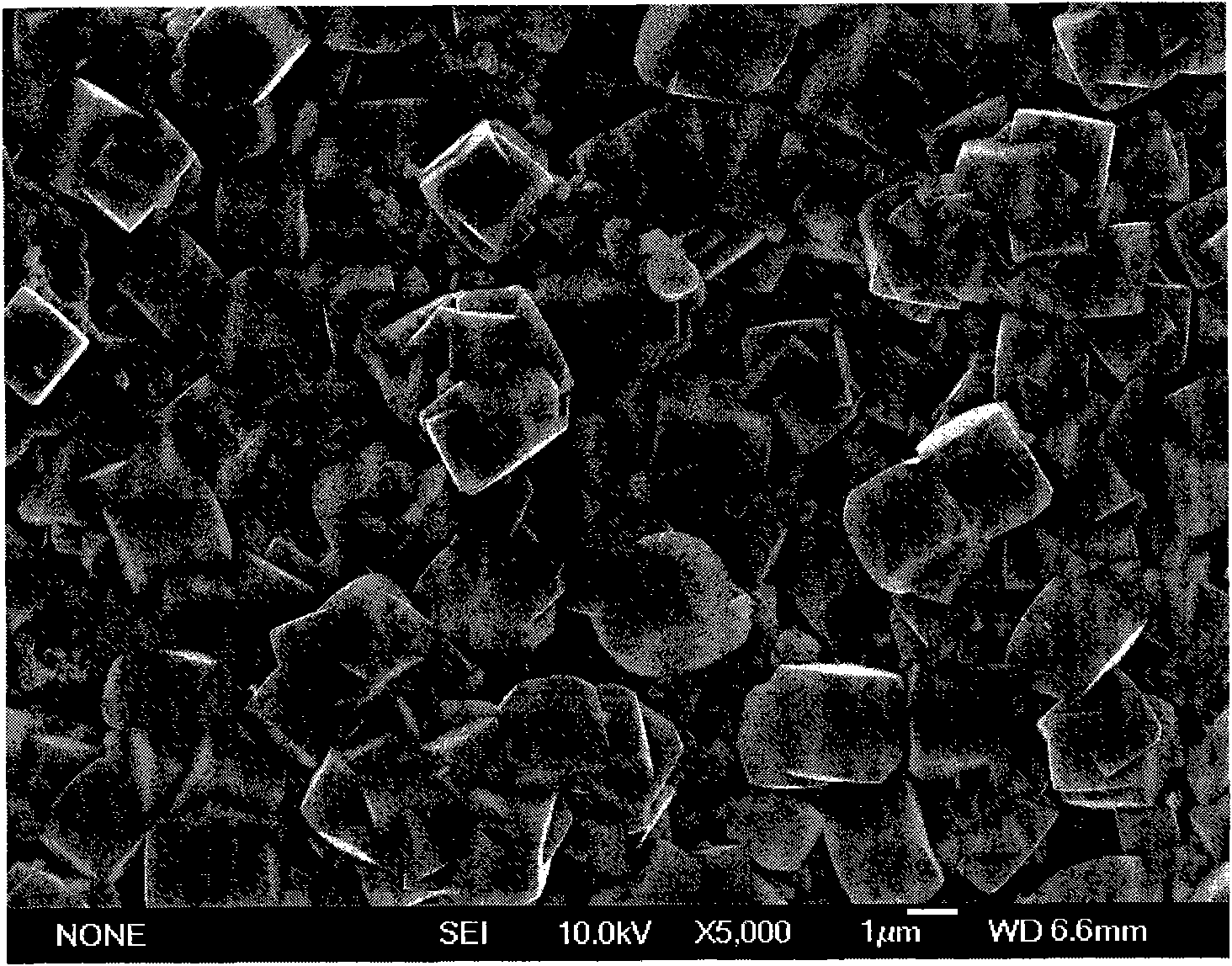

[0035] Polish the aluminum alloy sheet with No. 1-6 metallographic sandpaper first, then put the test piece into acetone and ultrasonically clean it for 10 seconds, and rinse the surface with deionized water; then use 0.1mol / L sodium hydroxide Solution etching, after alkali etching, it should be cleaned with running water in time; then the aluminum alloy sheet should be immersed in 5g / L titanium (IV) polyphosphate surface adjustment solution for surface adjustment for 1-2min; the aluminum alloy sheet after surface adjustment should be placed Put it into the phosphating solution p...

Embodiment 2

[0038] In the present embodiment, the formula that adopts phosphating solution is (containing per liter): Zn 2+ 5.8g, PO 4 3- 24g, F - 1.5g, Ni 2+ 0.8g, 1.2g ammonium molybdate, 0.6g guanidine nitrate, 0.4g salicylic acid; the phosphating treatment solution was prepared with deionized water, and the pH value of the phosphating treatment solution was adjusted to 3.5-3.7 with 30wt.% NaOH solution.

[0039] The pretreatment process and phosphating treatment process of the aluminum alloy sheet are exactly the same as the above-mentioned embodiment 1.

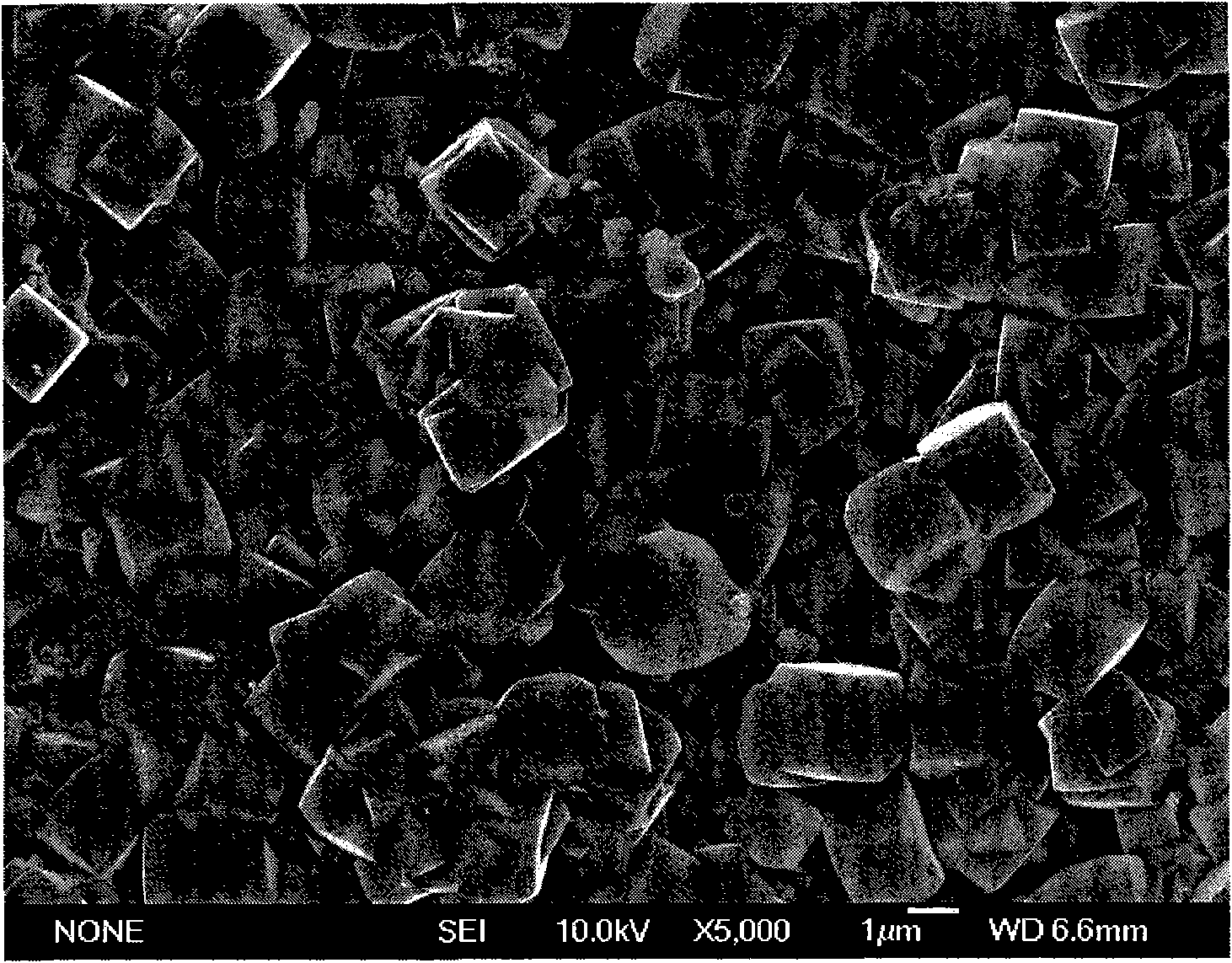

[0040] The phosphating film is gray black, the film layer is uniform and dense, and the film weight is 3.56g / m 2 . The copper sulfate spot corrosion test result was 137 seconds; the adhesion of the phosphating film reached the first grade.

Embodiment 3

[0042] In the present embodiment, the formula that adopts phosphating solution is (containing per liter): Zn 2+ 6.0g, PO 4 3- 24g, F - 1.8g, Ni 2+ 0.9g, 1.2g ammonium molybdate, 0.6g guanidine nitrate, 0.4g salicylic acid; the phosphating treatment solution was prepared with deionized water, and the pH value of the phosphating treatment solution was adjusted to 3.5-3.7 with 30wt.% NaOH solution.

[0043] The pretreatment process and phosphating treatment process of the aluminum alloy sheet are exactly the same as the above-mentioned embodiment 1.

[0044] The phosphating film is gray black, the film layer is uniform and dense, and the film weight is 3.77g / m 2 . The copper sulfate spot corrosion test result is 129 seconds; the adhesion of the phosphating film reaches the first grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com