Air bag restraint system gas generant based cracking barrel and near-people blasting method thereof

A gas generating agent and safety airbag technology, which is applied in the direction of compressed gas generation, blasting, and blasting cylinders, can solve the problems of toxic and harmful substances, environmental pollution, etc., and achieve the effects of easy handling, reduced safety hazards, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

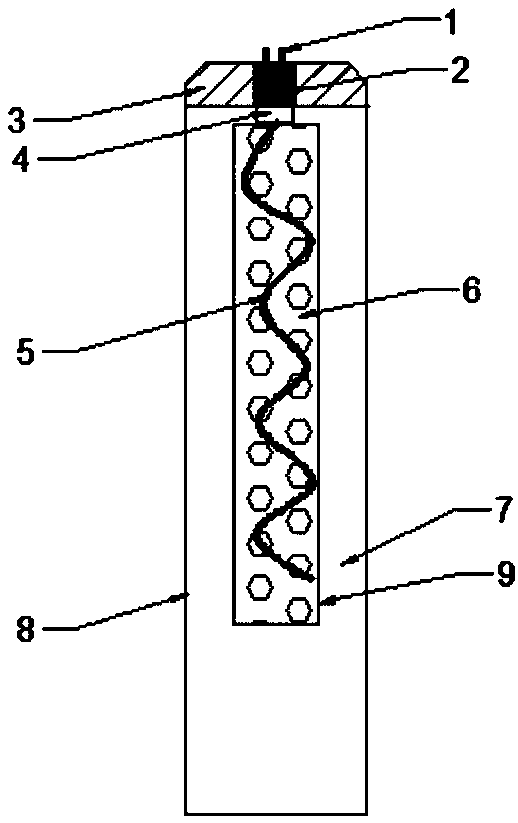

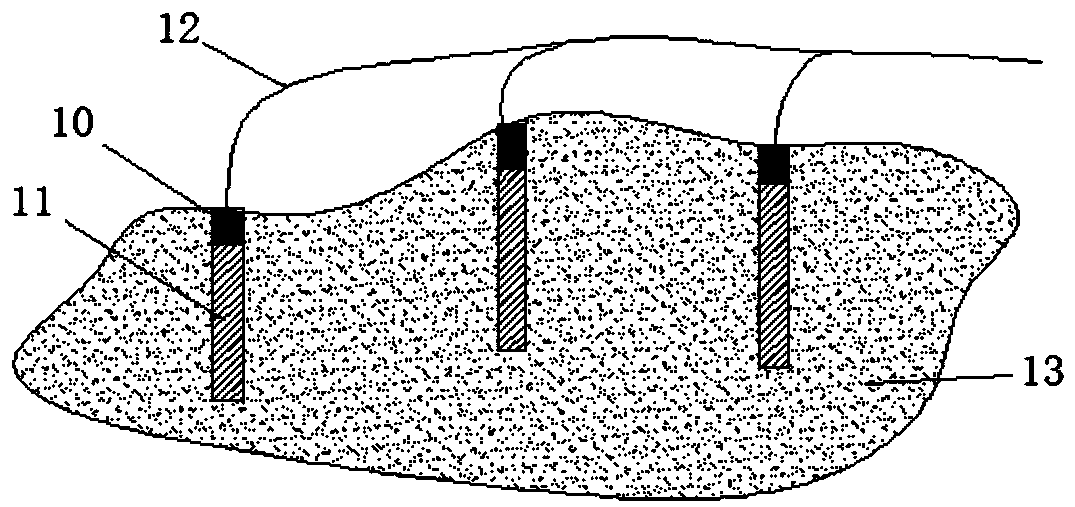

[0026] The cracking cylinder based on the airbag gas generating agent as shown in the figure includes a gas generating agent housing 9 and a gas generating agent 6. The gas generating agent 6 needs a certain pressure to trigger ignition. The gas generating agent includes an oxidant, Acrylate crosslinking agent, plasticizer, vinyl tri-2-methoxyethoxysilane lubricant, combustion agent guanidine nitrate and catalyst iron oxide; a certain pressure is set in the gas generating agent housing 9, and a There is a resistance wire 5, and the resistance wire 5 is connected to the plug 2 through the delay device 4 outside the gas generating agent casing, and the plug 2 is also provided with a pin 1 for connecting an external circuit. The gas generant housing 9 is also provided with a cylindrical combustion chamber housing 8, the combustion chamber hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com