Anaerobic pressure-controlled heating agent and use thereof

A heat-generating agent, anaerobic technology, applied in the direction of explosives, etc., can solve the problems of slow heating, inability to achieve instantaneous rapid heating, small heating energy, etc., and achieve the effect of simple formulation, excellent thermal stability, and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

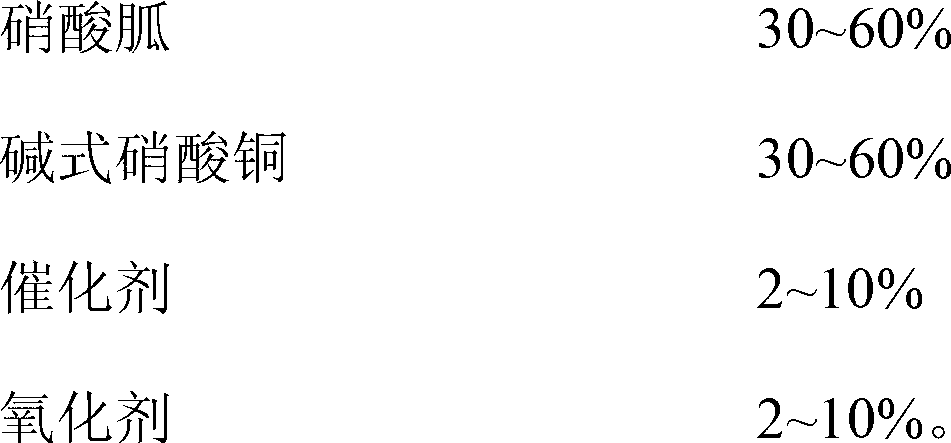

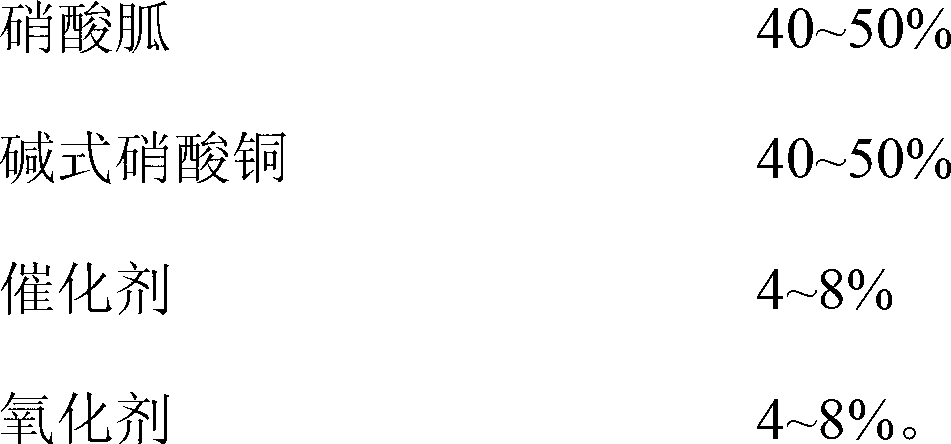

Method used

Image

Examples

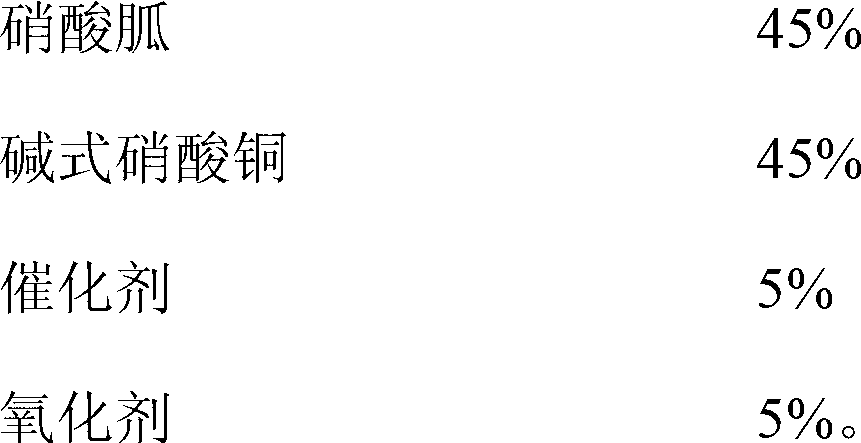

Embodiment 1

[0035] Fully mix 45g of guanidine nitrate, 45g of basic copper nitrate, 5g of ferric oxide and 5g of ammonium perchlorate with the binder in a mixer to form a uniform powder, and then granulate to obtain anaerobic pressure-controlled Fever.

[0036] The anaerobic pressure-controlled heating agent is tested, 40g of the drug is placed in a drug tube with an inner diameter of 18mm and a length of 300mm, and the drug is filled with the drug tube; the drug tube is placed in a carbon dioxide environment with an ambient pressure of 7.0Mpa; ignited Agent, the burning speed of test agent is 15~30m / s.

Embodiment 2

[0038] Fully mix 30g of guanidine nitrate, 60g of basic copper nitrate, 2g of manganese dioxide and 8g of ammonium perchlorate with the binder in a mixer to form a uniform powder, and then granulate to obtain anaerobic pressure-controlled heating agent.

[0039] The anaerobic pressure-controlled heating agent is tested, 40g of the drug is placed in a drug tube with an inner diameter of 18mm and a length of 300mm, and the drug is filled with the drug tube; the drug tube is placed in a carbon dioxide environment with an ambient pressure of 7.0Mpa; ignited Agent, the burning speed of test agent is 3~7m / s.

Embodiment 3

[0041] Fully mix 60g of guanidine nitrate, 30g of basic copper nitrate, 8g of copper oxide and 2g of potassium perchlorate with a binder in a mixer to form a uniform powder, and then granulate to obtain an anaerobic pressure-controlled heating agent.

[0042] The anaerobic pressure-controlled heating agent is tested, 40g of the drug is placed in a drug tube with an inner diameter of 18mm and a length of 300mm, and the drug is filled with the drug tube; the drug tube is placed in a carbon dioxide environment with an ambient pressure of 7.0Mpa; ignited Agent, the burning speed of test agent is 5~8m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com