A waste chemical combustion system, method and device

A technology of combustion device and combustion system, applied in the direction of combustion method, combustion type, application, etc., can solve the problems of combustion, explosion, rapid aging, and high friction sensitivity, and achieve the purpose of reducing rising speed, reducing operating cost, and reducing temperature resistance requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

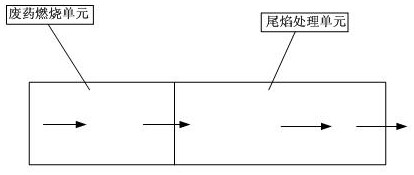

[0050] This embodiment provides a waste chemical combustion system, such as figure 1 As shown, the waste medicine combustion unit is included, and the waste medicine combustion unit has an ice cave structure, and waste medicine is placed in the ice cave structure, and the waste medicine combustion unit is connected with the tail flame processing unit; the ice cave structure is made of ice; the waste medicine is placed in the waste The tail flame produced by combustion in the ice cave structure of the drug combustion unit is introduced into the tail flame processing unit, and the tail flame processing unit treats the tail flame harmlessly.

[0051]During the burning process of waste medicine, because the surface where waste medicine participates in combustion is uncontrollable, the burning rate changes too much, which is easy to cause deflagration, which is very dangerous. In this embodiment, the waste medicine is burned in the ice cave, which can greatly suppress the rapid bur...

Embodiment approach 2

[0062] This embodiment discloses a method for burning waste medicine, such as figure 2 As shown, the waste medicine is placed in the ice cave for burning, and the hole of the ice cave can be connected with the tail flame processing unit, and the tail flame processing unit can process the tail flame produced by the waste medicine combustion. The waste medicine is any one or more of powdery waste medicine, crushed granule waste medicine, and fragmented waste medicine. Specifically, the waste drug can be a single powdery waste drug, crushed granule waste drug or crushed block waste drug, and of course it can also be a mixture of powdery waste drug and crushed granule waste drug, crushed granule waste drug and crushed block waste drug Mixed medicines, mixed medicines of powdered waste medicines and broken pieces of waste medicines, powdery waste medicines, mixed medicines of broken granule waste medicines and broken pieces of waste medicines, etc.

[0063] It should be emphasize...

Embodiment approach 3

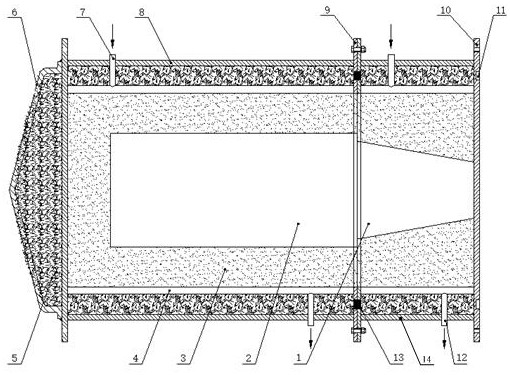

[0070] This embodiment discloses a waste medicine burning device, such as image 3 As shown, it includes: a waste medicine combustion assembly for burning waste medicine. The waste medicine combustion assembly includes a shell 8 and a heat insulator 3 installed in the inner cavity of the shell 8. The material of the heat insulator 3 is ice, and the heat insulator 3 is provided with the ice cave 2 as combustion chamber, and waste medicine is placed in ice cave 2 from the mouth of ice cave 2, and waste medicine burns in ice cave 2.

[0071] There is also a cooling channel 4 between the shell 8 and the heat insulator 3, and the cooling channel 4 is used for cooling liquid to flow. The purpose of cooling liquid flowing in the cooling channel 4 in this embodiment is to prevent the ice from melting too quickly, and the cooling liquid is preferably ethylene glycol or salt water at minus 5°C to minus 10°C. An insulating layer 5 is also filled between the shell 8 and the cooling chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com