Continuous synthesis process of guanidine nitrate

A technology of guanidine nitrate and chemical synthesis, which is applied in the field of chemical industry, can solve problems such as unstable product quality and yield, damage to raw material ratio, and difficulty in reaction control, and achieve the effects of reduced operating intensity, stable operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

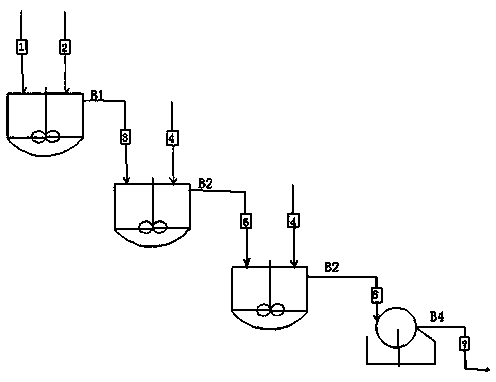

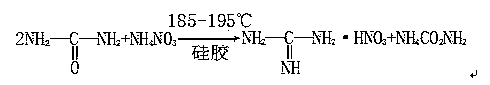

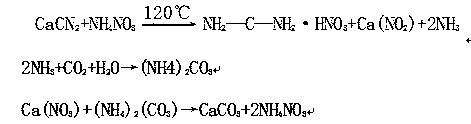

Method used

Image

Examples

Embodiment 1

[0033] In a melting kettle equipped with a thermometer, stirring, and a 500 ml feeding funnel, add 288 g of ammonium nitrate (3.6 mol) and 151.2 g of dicyandiamide (1.8 mol) respectively, start heating and melting at 120 ° C, and continue to heat up to 130 ° C , and the continuous reaction was started after holding for half an hour. In the reaction process, the feeding speed is controlled by two small screw feeders, and the raw materials are added to the melting kettle stably and evenly. The speed of adding dicyandiamide is 150g / h, and the speed of ammonium nitrate is 300g / h. The temperature is 130 ± 5 degrees, the average residence time is 1 hour, and the melted material overflows into the 500ml first-level reactor from the opening on the side of the melting kettle, and the temperature of the control first-level reactor is 180 ± 5 degrees, and the average residence time is 1 hour. , the speed of feeding ammonia is 15g / h, and the reacted material overflows from the opening on ...

Embodiment 2

[0035] In a melting kettle equipped with a thermometer, stirring, and a 500 ml feeding funnel, add 288 g of ammonium nitrate (3.6 mol) and 151.2 g of dicyandiamide (1.8 mol) respectively, start heating and melting at 120 ° C, and continue to heat up to 130 ° C , and the continuous reaction was started after holding for half an hour. In the reaction process, the feeding speed is controlled by two small screw feeders, and the raw materials are added to the melting kettle stably and evenly. The speed of adding dicyandiamide is 200g / h, and the speed of ammonium nitrate is 400g / h. The temperature is 130 ± 5 degrees, the average residence time is 1 hour, and the melted material overflows into the 500ml first-level reactor from the opening on the side of the melting kettle, and the temperature of the control first-level reactor is 180 ± 5 degrees, and the average residence time is 1 hour. , the speed of feeding ammonia is 15g / h, and the reacted material overflows from the opening on ...

Embodiment 3

[0037] In a melting kettle equipped with a thermometer, stirring, and a 500 ml feeding funnel, add 288 g of ammonium nitrate (3.6 mol) and 151.2 g of dicyandiamide (1.8 mol) respectively, start heating and melting at 120 ° C, and continue to heat up to 130 ° C , and the continuous reaction was started after holding for half an hour. In the reaction process, the feeding speed is controlled by two small screw feeders, and the raw materials are smoothly and evenly added into the melting kettle. The speed of adding dicyandiamide is 100g / h, and the speed of ammonium nitrate is 200g / h. The temperature is 130 ± 5 degrees, the average residence time is 1 hour, and the melted material overflows into the 500ml first-level reactor from the opening on the side of the melting kettle, and the temperature of the control first-level reactor is 180 ± 5 degrees, and the average residence time is 1 hour. , the speed of feeding ammonia gas is 7.5g / h, and the reacted material overflows from the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com